When looking at pumps, the one question every HVAC and Plumbing engineer will ponder is “which pump do I choose?” There are several factors that lead to the answer to this question. Today and next week, R.L. Deppmann Monday Morning Minutes (MMM) looks at seven steps to decide which pump to choose. This blog will focus on closed hydronic system selections, but the basic concepts can be used in plumbing and industrial selections. This will be one you want to reference often, so keep the link handy.

Today we will look at:

- The Type of Pump

- NPSH

- Pump Speed

Let’s with the capacities of the pump. The assumption is that the engineer has the capacities and understands whether the application will require constant or variable speed pumping. We will have links to past MMM which will help fill in more detail on the seven steps.

Step One: Type of Pump to Select

One of the first decisions will be the selection of the type of pump. We assume the brand you want to select will be Xylem Bell & Gossett since that is the manufacturer R. L. Deppmann (RLD) represents in Michigan and Ohio.

Capacities:

The pump you select may be inline pipe mounted, inline floor mounted, end suction, or double suction. There are other types but, in the HVAC world, these are the common offerings. The first consideration is capacity. Historically, inline pipe mounted pumps are used for small capacities. Double suction pumps are used for large capacities. End suction pumps are used for most of the applications we would call “in the middle.” Inline does not mean mounted in the piping in the air. It means the pump inlet and outlet are “inline” with each other. The inline floor mounted covers both the large capacities and middle capacities.

How to Pick an HVAC Centrifugal Pump: Types of Pumps & Seismic Activity

Here are some guidelines to get started. Please note that many of the pump models overlap in capacity and horsepower, so feel free to explore.

Pump Selection - Starting Point

| Type of Pump | Horsepower* | Pipe Size** | Life Expectancy (Years)*** | Comments |

|---|---|---|---|---|

| Inline Pipe Mounted | 1/12 HP to 5 HP | ½” – 3” | 8 - 16 | Lower First Cost, Lower Installation Cost |

| Inline Floor Mounted | 5 HP to 75 HP | 3” to 8” | 13 - 16 | Lower First Cost |

| End Suction – Base Mounted | 5 HP to 75 HP | 3” to 8” | 20 - 23 | Longer Life, Easier Overall Service |

| Double suction – Base Mounted | 75 HP and Up | 6” and up | 40+ | Highest First Cost, Longest Life |

** Once again, the pumps are available in capacities much greater than shown, but this is what R. L. Deppmann normally sees for usage.

*** DOE estimates and referenced this article: https://www.csemag.com/articles/faq-doe-2020-what-engineers-need-to-know/. DOE did not rate the double suction and inline boosters. This is an RLD experience.

The chart above is a starting point R. L. Deppmann uses. The inline pump, in general, has fewer parts and will cost less to purchase. The inline pump configuration has the inlet and outlet in the same direction and will cost less to install. One caveat to this is the larger inline pumps. Often, the larger 30 HP and above, inline pumps will require some overhead rigging to service the motor. This will increase the installation cost. The inline pump has a shorter expected life so the lifetime cost of an inline pump may be greater than an end suction base mounted style.

HVAC Centrifugal Pump Coupling Types – Close, Split, Flexible

Life Cycle Cost:

It is all about the client. If the owner expects to sell the building in 5-7 years and the initial construction cost, or first cost, is more important than the life of the pump, then lean toward the inline. If your client has a university building and expects your grandchildren to attend in the same building you went to, then think base mounted end suction and even double suction.

How to Pick an HVAC Centrifugal Pump: Designing for Owner Satisfaction

Picking a Centrifugal Pump: Choosing Single or Double Suction

The life expectancy is shown in the chart above. Notice the base mounted end suction life vs. the floor mounted inline life. Here is an example of why life is different. The base mounted end suction pump has a set of bearings in the motor and a set of bearings in the pump. The inline floor mounted has a set of bearings in the motor and a bushing in the pump.

Mechanical Room Floor Space:

Obviously, the inline pipe mounted pump itself will use less floor space. The double suction base mounted pump will take the most floor space, but it is also the largest capacity.

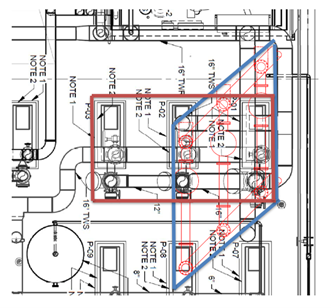

There are marketing discussions back and forth about the space used by base mounted vs. floor mounted inline pumps. There is no question that the inline pump itself is smaller than the base mounted end suction pump. The engineers should look at the installation space for both including manufacturer’s instructions. You will find the space saved for either type is normally so small as to not be a consideration. Look at the sketch above which shows the base mounted end suction space in the red box and the inline in the blue box. It would be hard to make a space argument for either installation.

Large Centrifugal Inline Pump Installation

Choosing an HVAC Centrifugal Pump – Mechanical Room Space

Step Two: NPSH or Net Positive Suction

NPSH is especially important when it is important. The net positive suction head is the required absolute pressure at the inlet to the pump to make sure the water does not vaporize in the pump impeller. Normally in closed systems there is little worry, but you need to be aware of it. It can be an issue with higher temperature water over 200°F and in open systems such as cooling towers and steam condensate pumps. This is an advanced subject but, when it is an issue, it will influence the type of pump selected as well as the model selected.

If you need to understand this now you can visit our five-part series:

Net Positive Suction Head (NPSH): Terms and Definitions

Net Positive Suction Head (NPSH): Safety Factors

Net Positive Suction Head (NPSH): NPSH Available

Net Positive Suction Head (NPSH): Gauge Readings

Net Positive Suction Head: Good Cooling Tower Pump Piping Practice

Step Three: Pump Speed or Motor Type

You are in a pump selection program such as the B&G ESP Systemwize program. Once you select the type of pump and enter the capacities you will see a series of selections. One choice at this point is speed. If you are looking at inline pipe mounted pumps you may also see an option for ECM motors.

ECM motors are available on many inline pumps. They are limited due to the maximum horsepower currently available. These pumps may give you variable speed function without a separate drive or VFD.

What are ECM Pumps & ECM Smart Pumps

How Can an ECM Smart Pump Save Energy?

Smart ECM Pump Applications – Variable Speed Heating & Cooling System

Using ECM Smart Pumps in Secondary Hydronic Systems

Using ECM Smart Circulator Pumps in Primary Pump Applications

If the ECM option is not available, the second thing you may see is pump speed in a premium efficiency motor. These are most of the motors we see in specifications and they are listed as IEC-3 type by the International Electrotechnical Commission (IEC).

In general, 1750 RPM motors will be quieter and last longer than 3500 RPM IEC-3 or premium efficiency motors. That said, 3500 RPM motor selections normally will have a smaller pump and less cost to the motor. If the first cost is the prime directive, you may choose to look at 3500 RPM selections.

How to Pick an HVAC Centrifugal Pump: Motors for HVAC Centrifugal Pumps

Finally, you may find selections with ultra-premium motors referred to an IEC-5 or PMAC. These will have enough efficiency increase to be looked at in many systems. Here is a three-part series on motor types.

Permanent Magnet Motors & Electronically Commutated Motors

Permanent Magnet & Electronically Commutated Motors in Hydronic Systems

The Advantages and Disadvantages of Permanent Magnet Motors

Next week we continue with part 2 including where on the pump curve to select, efficiency, room to move, and other considerations.