The cooling tower pump calculations are completed, the project is bid, the Bell & Gossett pumps scheduled are awarded and installed. There is a noise coming from the pump. The first thing you hear from everyone, “The pump is making noise so it must be cavitating!” Today, the R.L. Deppmann Monday Morning Minutes examines gauge readings to determine the actual available NPSHA.

The cooling tower pump calculations are completed, the project is bid, the Bell & Gossett pumps scheduled are awarded and installed. There is a noise coming from the pump. The first thing you hear from everyone, “The pump is making noise so it must be cavitating!” Today, the R.L. Deppmann Monday Morning Minutes examines gauge readings to determine the actual available NPSHA.

Gauge Readings Start with a Gauge

To read out a gauge on the cooling tower pump suction, we need a gauge. There is a chance the readings may be less than “0” PSIG so make it a compound gauge. Accuracy is also important so use a grade 2A ½% accurate gauge. The normal cooling tower pump head is typically low, so select the gauge with a lower maximum pressure that still works for the discharge reading. An example would be the Miljoco model P4509LX-004 with a range of 30” to 60 PSI. This will give you a readout in 1” Hg increments on the vacuum side.

How Do I Check NPSH Feet When the Gauge Reads Inches HG?

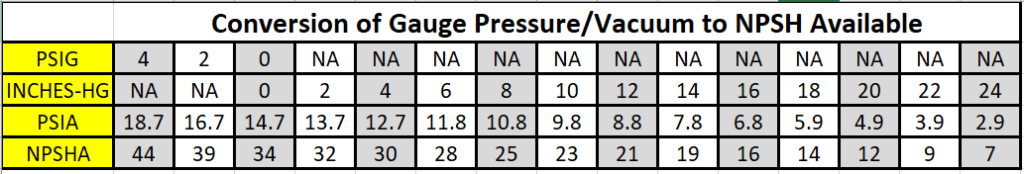

There are plenty of links to equations on the internet but here is a quick chart I made to convert a reading in inches of HG to absolute feet of head. But first there is a correction to think about when you take the reading.

When reading pressure gauges anywhere in the system, you should decide if a velocity head correction will make a difference. The link will take you to an explanation I made a while ago on this subject.

Good design practice keeps the suction piping velocity low in cooling tower applications. The low velocity should make any velocity head correction readings very low. The example pump from parts 2 and 3 had a 6” suction size and a design of 1000 GPM. Using the formula in the link above, we find the correction to be 1.9 feet. This is added to the NPSHa from above.

Example 1: The Miljoco 4509LX-004 compound gauge reads 8” on the example 6” pump. The chart above shows the 8” HG reading gives us 25 feet NPSHA. The velocity head correction is 1.9 feet. The actual corrected NPSHa is 25 + 1.9 or about 27 feet.

We could also use the system syzer and a simple subtraction to find the velocity head correction in feet.

Example 2: A gauge on a cooling tower pump with a 10” suction reads 4” HG. The flow is 3000 GPM. What is the reading including the velocity head correction?

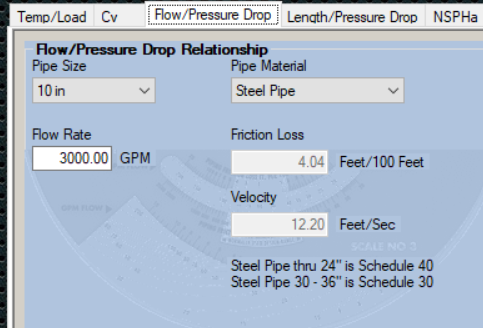

Step 1: Go to the electronic system syzer Flow/Pressure Drop tab. Change the temperature to 85⁰F. Select 10” steel pipe at 3000 GPM.

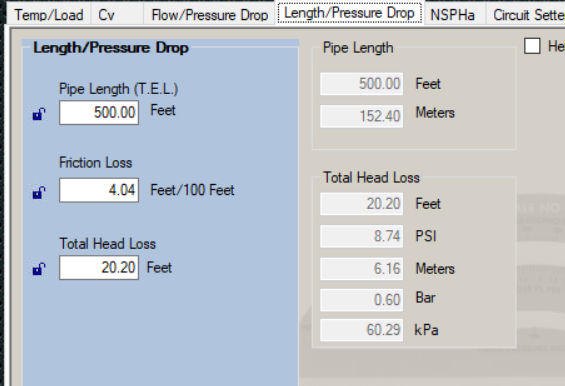

Step 2: Go to the Length/Pressure drop tab. It defaults to 500 feet with no fittings. This is fine for what we are doing here.

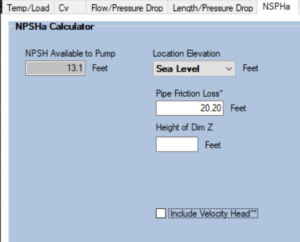

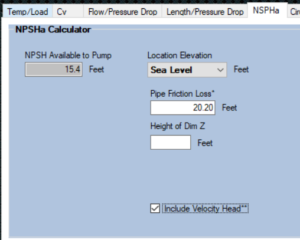

Step 3: Go to the NPSHa tab. The height defaults to nothing and that is fine. Notice the NPSHa reads 13.1 feet. Now check the “Include velocity head” button. Notice the NPSHa is now 15.4 feet. The correction is the difference: 15.4 – 13.1 = 2.3 feet.

Step 4: Take the gauge reading of 4” and look at the chart above. The chart indicates 30 feet of NPSHA. Add the 2.3 feet and the corrected NPSHa is 32.3 feet.

In part 5, we will complete this series by looking back at some cooling tower pump suction piping recommendations.

Check out the rest of the Net Positive Suction Head (NPSH) Series:

Part One – Terms and Definitions

Part Two – NPSH Safety factors

Part Three – Calculating NPSH Available

Part Five – Good Cooling Tower Pump Piping Practice