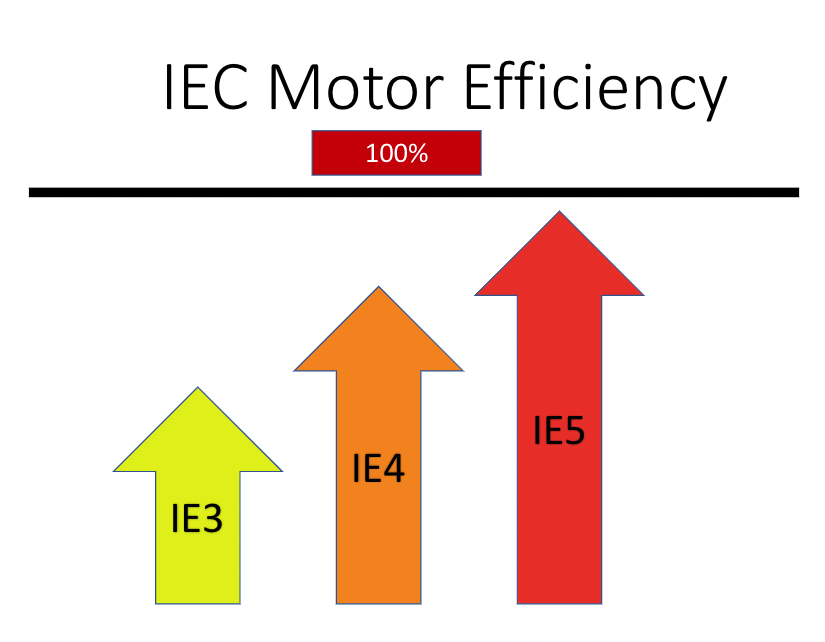

You understand the differences between premium efficiency (IE3) motors and PMAC or ECM motors (IE4&5). You understand the cost implications of both styles of motors. Is there anything you need to know about selection and commissioning of these motors? The R. L. Deppmann Monday Morning Minutes may offer a few tips.

You understand the differences between premium efficiency (IE3) motors and PMAC or ECM motors (IE4&5). You understand the cost implications of both styles of motors. Is there anything you need to know about selection and commissioning of these motors? The R. L. Deppmann Monday Morning Minutes may offer a few tips.

What is Special About Selecting Permanent Magnet Motors?

We engineers love lists. Here is a list of selection thoughts on PMAC motors for pumps.

- PMAC motors are only available to about 30 HP. Verify the motor is available in the HP you need and the approximate increase in cost before you specify them.

- PMAC motors tend to be a smaller frame size than standard premium efficiency motors. Make sure the pump frame and the motor frame match. These motors do not always follow the standard NEMA T-frame motor frame charts currently published.

- When replacing an existing motor, verify if the pump needs any modification since the frame size maybe smaller.

- These motors MUST have a variable frequency drive to work (VFD). They will not work with across the line or part load starters.

- You cannot use a drive with a manual or automatic bypass because the motor needs a VFD.

- When selecting the pump, use the true synchronous RPM curve. Example: 1800 RPM, not 1765 RPM.

Commissioning the VFD on a Permanent Magnet Motor Application

The startup of the variable speed drive (VFD) on a PMAC application requires some special knowledge about the drive and the motor. If the pump supplier is supplying the drive and the startup services, there may be less RFIs requesting information not shown in the submittals. Here are a few things of importance.

- The VFD should be supplied for use with a permanent magnet motor. Many PMAC motor manufacturers list drives they have tested with their motors. This might be a time to have the drive provided by the pump supplier for unit responsibility.

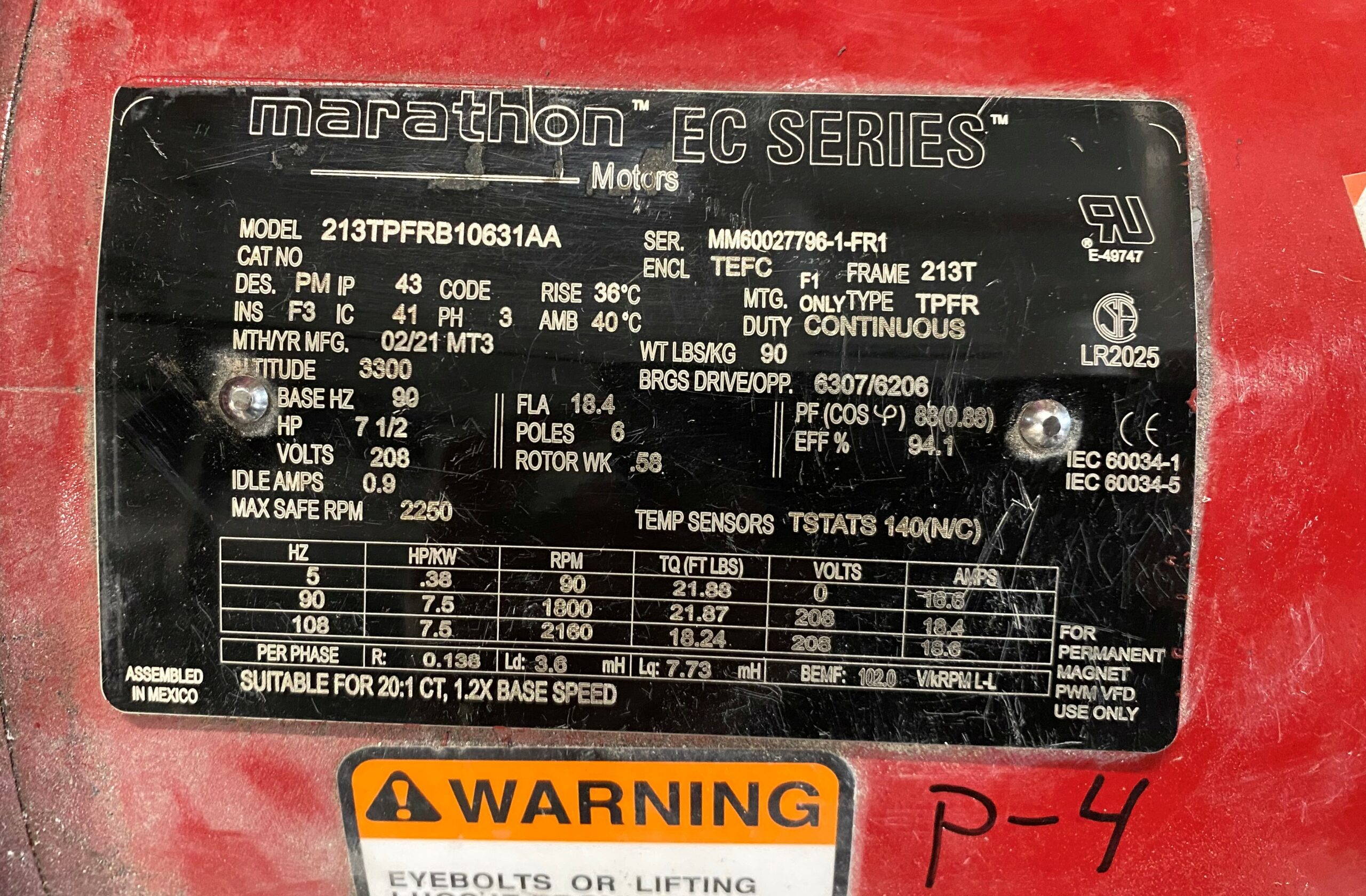

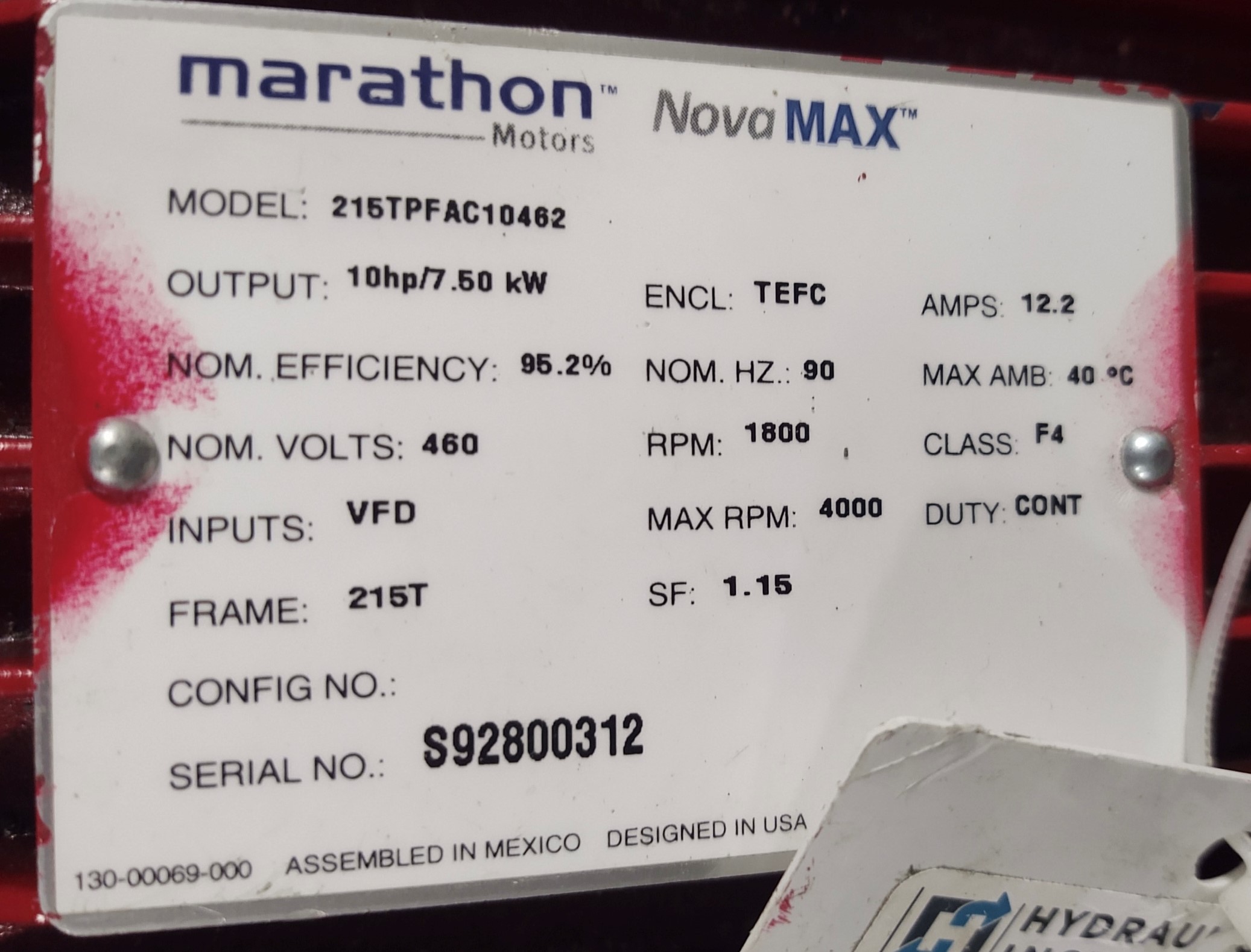

- I mentioned the hertz in the last article, and some people thought it was a typo. It was not. The design speed of the motor is NOT running at 60 Hz. The motor has a large speed range and the person setting up the VFD has to “tune” the motor to the correct speed. One motor may be 150 Hz to get 1800 RPM while another might be 90 Hz. This is motor specific and may or may not be on the motor tag.

- Some added points are the rotor resistance, the two inductive values of Ld and Lq, and the emf back voltage. The point is, there is a lot of information needed to set up the drive. It is not something a novice should tackle. The specifier should require a startup report for the owner with the PMAC specific values in the report.

Look at the two motor tags above. The same manufacturer has one tag with all the information needed and one tag without. The R. L. Deppmann Startup and Warranty Department technician would have the correct information available before getting to the project.

Advantages and Disadvantages of Permanent Magnet Motors?

Here is a brief and possibly incomplete listing of the advantages and disadvantages of using a PMAC motor over a premium efficiency motor.

ADVANTAGES

- The PMAC motor has a higher efficiency than the motors you currently specify. This efficiency is even more pronounced at lower speeds and lower horsepower.

- The higher efficiency produces lower electric bills for your client. Payback may be as low as 3 years.

- The PMAC motor is noticeably quiet. The motor is quiet at full speed and has much less “whine” at lower speeds.

- ECM motors are only available in lower horsepower, but they normally have a variable speed adjustment inside of them and they do not need a drive. Visit part 1 of this series for more detail.

- ECM “Smart pumps” also include some control functions for the pump. Again, visit part 1 of this series for more information.

- If you are an early adopter engineer, this is the latest and most efficient choice for you.

DISADVANTAGES

- These motors come with a first cost premium. They are not required by code so the owner and engineer should be on the same page before the value engineering options come forward.

- The project may have some pumps with PMAC motors and some where the PMAC is not available. The plans and specifications should be clear on this.

- VFDs must be supplied for these motors to work. The drive must be specified for use with PMAC motors.

- The startup of the VFD and pump will need more professional knowledge and motor information. Deppmann does their own startups with trained professionals.