We continue to look at air issues and swirling issues in this third segment of cooling tower pump suction piping. We also provide you …

Open Cooling Tower Pump Suction Piping Part 2

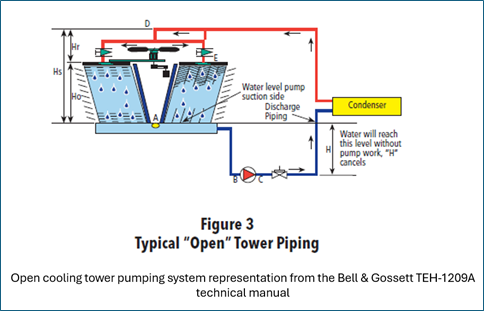

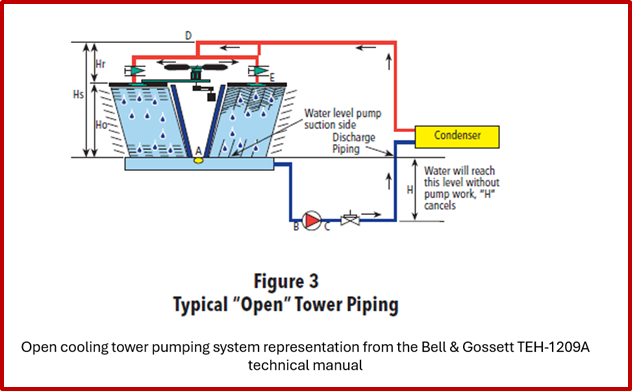

Centrifugal pumps find open cooling tower applications are the toughest duty there is in hydronic cooling systems. We are always concerned about the pressure at …

Open Cooling Tower Pump Suction Piping Part 1

Centrifugal pumps find open cooling tower applications are the toughest duty there is in hydronic cooling systems. Pumps do best with piping systems that provide …

Open System Curves in Hydronic & Plumbing Systems

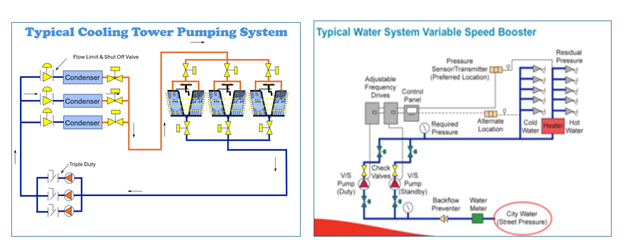

System curves give insight into energy analysis, pump operation, and control setting analysis. Unlike closed hydronic systems, open systems rarely have a system curve that …

Minimum Flow in a Variable Speed Pump: A Great Example

What is the minimum flow rate a variable speed pump can provide without damage to the pump? This is a question every engineer should ask …

Pump Suction Piping Rules – Cooling Tower Pumps and Piping – Part 8

Traditional hydronic piping system designers use tools such as the Xylem Bell & Gossett System Syzer for pipe sizing. You may find this program at http://completewatersystems.com. Tower manufacturers, the Hydraulic Institute (HI), and Bell and Gossett all suggest lower velocity for pipe selection in cooling tower pump suction piping. Bell and Gossett has several pipe sizing suggestions…

Pump Suction Piping Rules – Cooling Tower Pumps and Piping – Part 7

This week we continue our suggestions for tower pump suction piping. In order to minimize problems with air, noise, and NPSH at the tower pump, Bell and Gossett recommends you try to keep high pressure drop devices out of the suction piping and also keep the velocity low. Let’s examine high pressure drop device this week.

Pump Suction Piping Rules – Cooling Tower Pumps and Piping – Part 6

Over the last several weeks we discussed the feared NPSH and showed it is rarely an issue at design conditions. More often than not, noise and pressure problems are caused by air in the suction piping system. The suction pipe, in many cooling pumping systems, is under very little pressure. In fact, the suction of the pump could be under a vacuum.

It’s all about Pressure – Cooling Tower Pumps and Piping – Part 5

Last week the R. L. Deppmann Monday Morning Minute gave an example of a pump selection for which we applied the margin multipliers to arrive at 24.5 feet of net positive suction head required or NPSHR. Now let’s turn our attention to the cooling tower pump suction piping and net positive suction head available or NPSHA. [Read more…]

It’s all about Pressure – Cooling Tower Pumps and Piping

Last week the R. L. Deppmann Monday Morning Minute left you with a multiplier of 1.3, 1.5, or 2.0 to use with the pump NPSHR. Let’s look at an example this week using the suction energy formula we introduced last week and add one more margin to the formula.

- Page 1 of 2

- 1

- 2