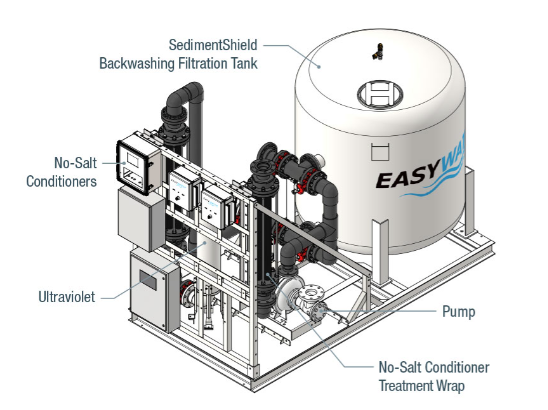

External water treatment in cooling tower systems will save labor and operational costs. It also saves the planet by reducing your clients’ dependance on chemicals …

Open Cooling Tower Systems — External Water Treatment Options

When people think of water treatment, they think of adding chemicals to the water to change it. That is the internal water …

Open Cooling Tower Systems — Internal Water Treatment Options

Cooling tower water will contain a variety of contaminants which are bad for the system and bad for people around the tower. Due …

Open Cooling Tower Systems — Water Treatment Options Overview

Dirt and Particulate are visible signs of trouble brewing in your open cooling tower system. Unfortunately, the things you cannot see brewing in …

A Cooling Tower Choice Solves Water Quality Issues and Saves the Planet

What’s lurking in your traditional open cooling tower basin? There is increasing concern about the sediment build-up, algae growth, and bacteria growth in open cooling …

Tired of Water Quality Issues with Cooling Tower Basins?

What’s lurking in your traditional open cooling tower basin? Today, there is a growing concern about the sediment build-up, algae growth, and bacteria growth in …

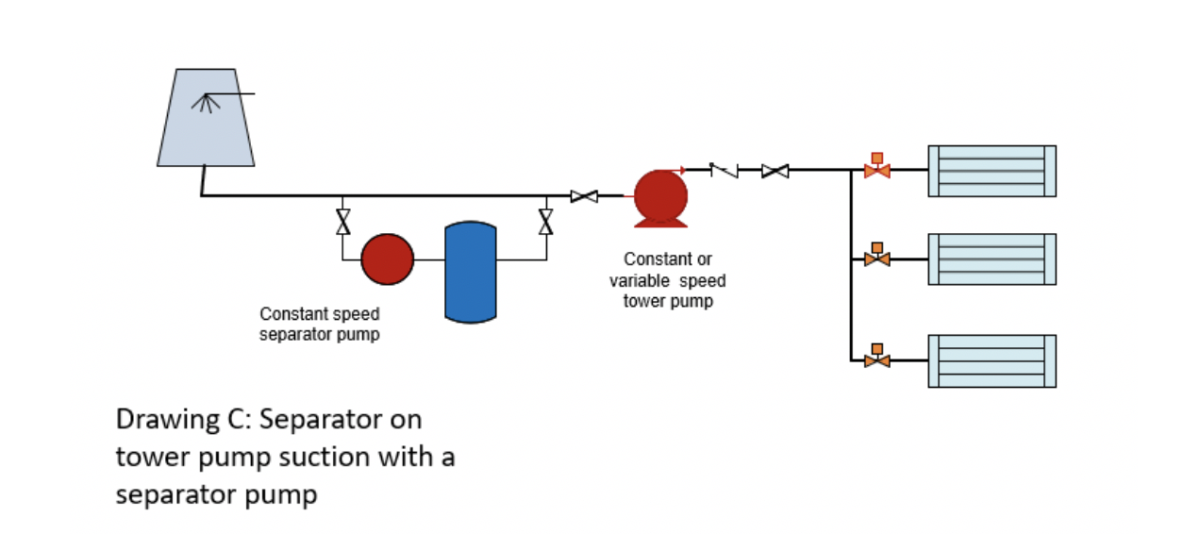

Primary – Secondary Sediment Separator Piping in Variable Flow Cooling Tower/Condenser Water Systems

The last R. L. Deppmann Monday Morning Minutes offered suggestions for the use of a Griswold sediment separator in a variable flow tower system. The …

Strategies for Water Use Efficiency – Cooling Tower Selection – Part V

Today’s building owner’s have many opportunities to improve water use efficiency. ASHRAE Standard 189.1 identifies a few areas to focus on reducing water use specific to cooling towers. The last four issues of Deppmann’s Monday Morning Minutes has discussed specific strategies to improve water use efficiency using current Cooling Tower and Advanced Water Treatment technology advancements in design. [Read more…]

Strategies for Water Use Efficiency – Cooling Tower Selection – Part IV

Most new chillers can now handle variable flow through the condenser providing many opportunities for operational savings. As the cooling tower is an integral part of this system, it is important to understand the effect of flow rate changes and how to insure your cooling tower can provide optimal savings while operating [Read more…]

Strategies for Water Use Efficiency – Cooling Tower Selection – Part III

In this issue, we will discuss the changing requirements specific to “cycles of concentration” in cooling tower applications. In addition, we will review the effect of increasing cycles of concentration and provide solutions to improving these results. ASHRAE Standard 90.1-2010 code change effective 10.18.2013 states [Read more…]

- Page 1 of 2

- 1

- 2