The Hydraulic Institute (HI) is a global authority on pumps and pumping systems. Think of them as the ASHRAE of pump design and testing. HI, in their publication of standards, defines NPSH as the suction pressure that will cause the total head of the pump to be reduced by 3%, due to flow blockage from cavitation. It does not say that NPSHR or net positive suction head required is where cavitation begins. What do we do with a statement like that!?

The Hydraulic Institute (HI) is a global authority on pumps and pumping systems. Think of them as the ASHRAE of pump design and testing. HI, in their publication of standards, defines NPSH as the suction pressure that will cause the total head of the pump to be reduced by 3%, due to flow blockage from cavitation. It does not say that NPSHR or net positive suction head required is where cavitation begins. What do we do with a statement like that!?

Testing a Pump for NPSH

The place where cavitation begins is called incipient cavitation and can be from 2 to 20% greater than the NPSHR reported on the pump curve. In addition, NPSHR is a tested value, the test is with clear un-aerated water; not dirty, highly aerated, tower water. Pumps also have manufacturing tolerances which may affect the number.

To reduce the chance of damage to the pump from cavitation, we need to use a larger number than the pump net positive suction head required. A few years ago, some HI contributors defined some margins to apply to the published pump NPSHR with different systems and pump types. The margin depended on the application and the SUCTION ENERGY of the pumps. Your pump representative can help you determine the exact margin, but I will offer some insight that gets you through 99% of the tower pump selections you may have.

Safety Factors to Use with NPSH Required

If your B&G cooling tower pump is under 100 HP and the motor is name-plated under 1800 RPM, use a margin or factor of 1.5. If the pump is larger than that, contact us to check the suggested margin.

In addition to the margin suggested by the Hydraulic Institute, I suggest another safety factor. When we are calculating the net positive suction head available, we may encounter other errors. The piping design may change slightly as the contractor installs the system. There are balancing tolerances to the flow rate which may result in slightly higher flows and, therefore, higher NPSHR. The tower elevation may change with different manufacturers. The water quality may not be perfect. All of these affect the calculated NPSHA. I suggest you add an additional 5 feet to the required NPSH to account for some slight variation from design to install. If you want more detail on suction energy, take a look at: Where Cavitation Begins – Cooling Tower Pumps and Piping and It’s all about Pressure – Cooling Tower Pumps and Piping.

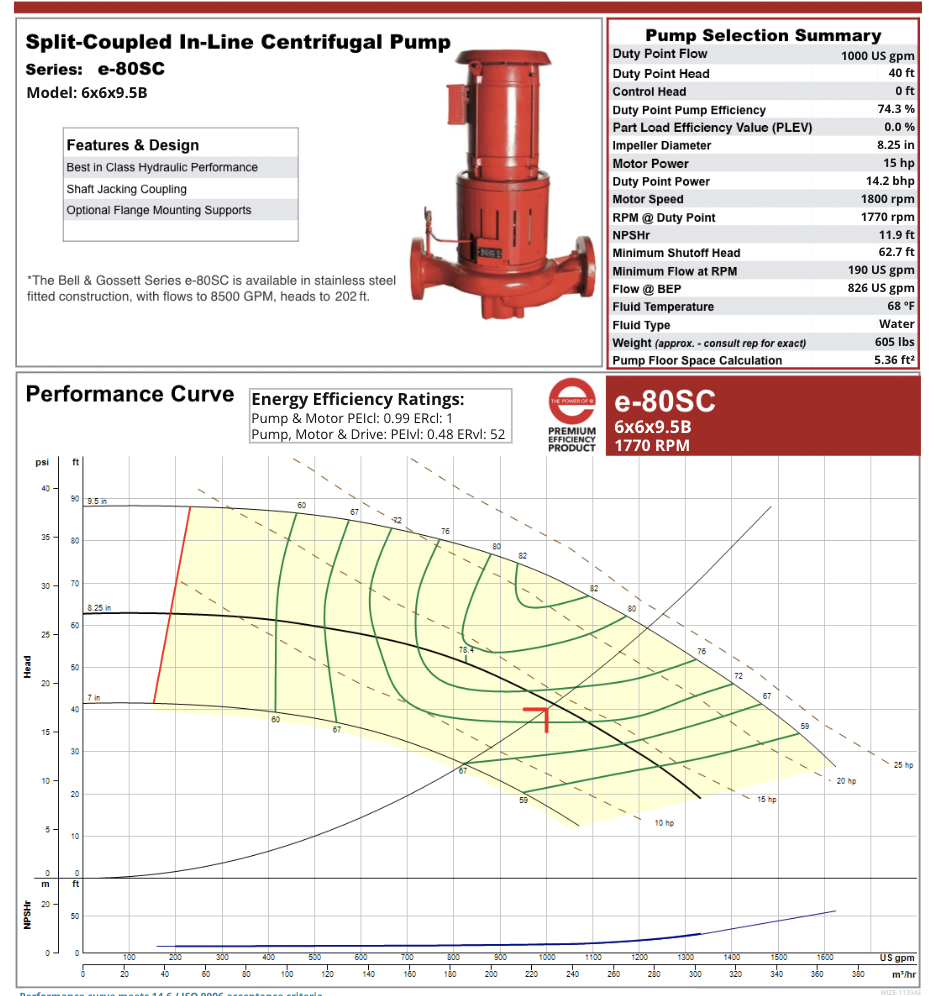

Example: Assume we have a required cooling tower pump capacity of 1000 GPM at 40 feet. The engineer wants to use a vertically mounted inline pump to reduce space requirements. They select a B&G e-80SC-6X6X9.5B with a constant speed 15 HP, 1770 RPM motor. The NPSHR required is 11.9 feet.

What is the minimum NPSH available I would suggest for this pump? Using the suggestions above: (11.9 X 1.5) + 5 = 22.85 or 23 feet absolute. This pump would be acceptable all the way down to 10” HG on a compound pressure gauge.

Next week the R. L. Deppmann Monday Morning Minutes will look at calculating the available NPSH.

Check out the rest of the Net Positive Suction Head (NPSH) Series:

Part One – Terms and Definitions

Part Three – Calculating NPSH Available

Part Four – Gauge Readings

Part Five – Good Cooling Tower Pump Piping Practice