Can I and should I specify permanent magnet motors (PMAC) on my hydronic system pumps? The last R. L. Deppmann Monday Morning Minutes showed the differences between PMAC, IE4, and premium efficiency motors, IE3. Today, we look at the economics of the choice.

Can I and should I specify permanent magnet motors (PMAC) on my hydronic system pumps? The last R. L. Deppmann Monday Morning Minutes showed the differences between PMAC, IE4, and premium efficiency motors, IE3. Today, we look at the economics of the choice.

A Huge Advantage of PMAC Motors in Hydronic Systems

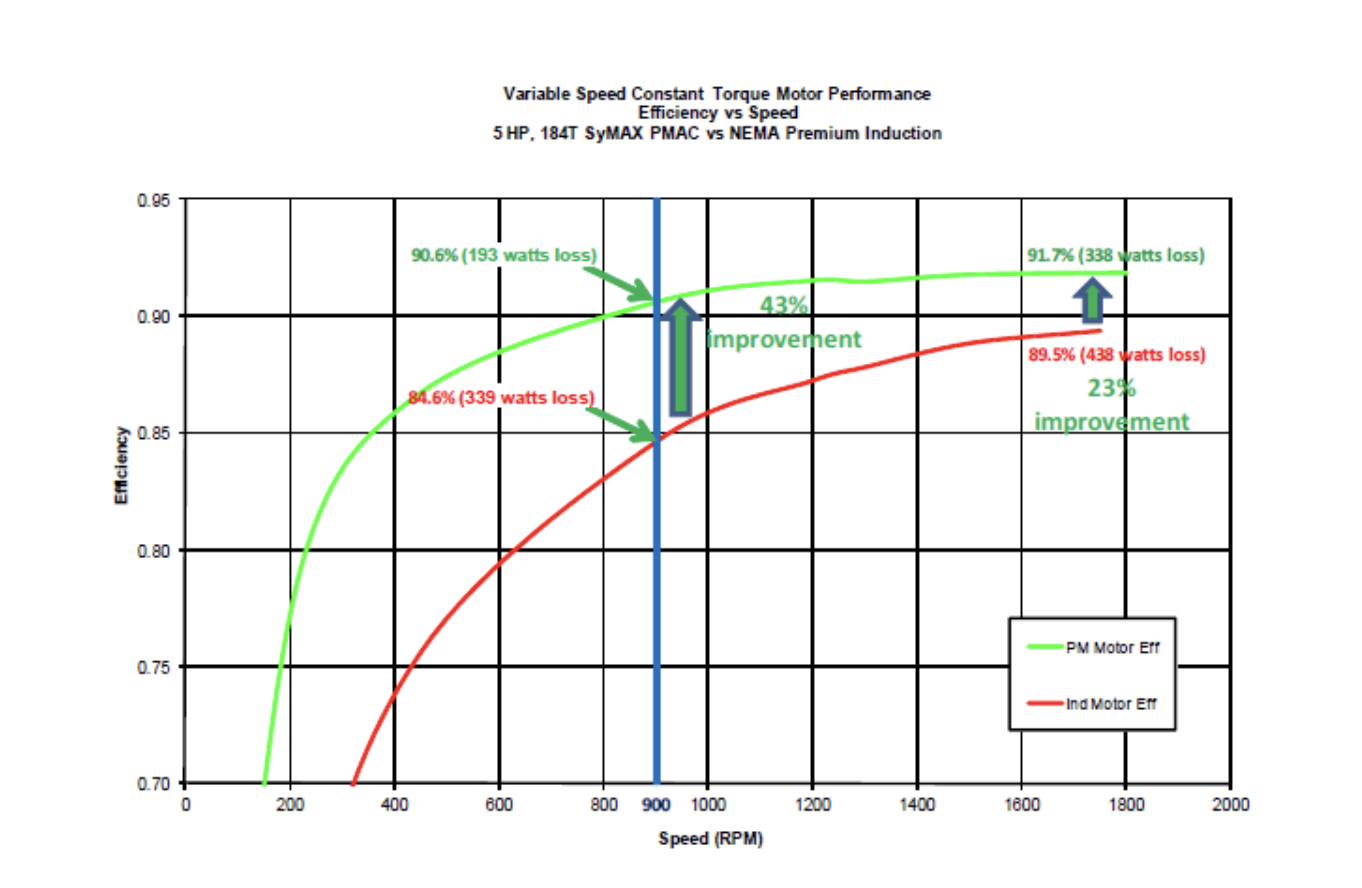

Our friends at Marathon®Motor, Regal Rexnord Corp., shared some information about their SyMAX®PMAC motor vs. their premium efficiency motor at part speed. We provided you a chart that showed a 1 to 3% efficiency increase at full speed. The attention-getter was the 6% efficiency increase at 50% speed. Particularly important since hydronic secondary or primary variable pumps spend most of their time at reduced speed. How much energy can we save using these ultra-premium efficiency motors?

Pump Operational Cost Savings using PMAC Motors

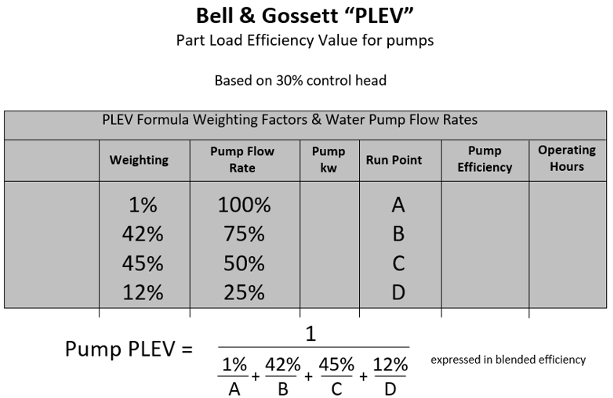

Most hydronic pumps operate at part load and part speed most of the time. The load analysis I am using is the Bell & Gossett Part Load Efficiency Valve or PLEV.

Briefly, this says that 87% of the time the pump will operate at 50 to 75% of the load. This also means that the speed of the pump will be just slightly higher than the same percentage subject to the control head used. That is the area where these PMAC motors save the most compared with the premium efficiency motors we currently specify.

Briefly, this says that 87% of the time the pump will operate at 50 to 75% of the load. This also means that the speed of the pump will be just slightly higher than the same percentage subject to the control head used. That is the area where these PMAC motors save the most compared with the premium efficiency motors we currently specify.

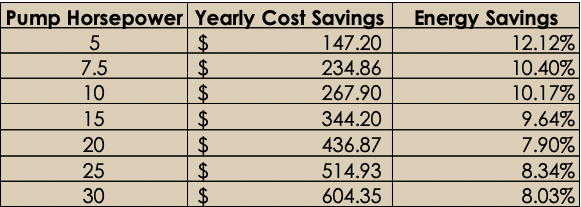

The numbers will change based on the pump selected and the load profile. For simplicity, I will use twelve cents per KWH and 365/24 hours. You can adjust as needed for your analysis. For both set of numbers, I am using the Bell & Gossett e-1510 high efficiency base mounted pump series which already save 10% over the lower efficiency competitors. Here are the numbers.

At first you may view the dollars as small. Look at the pump energy saved just because of the IE4 motor efficiency. Where else can you get 10% reduction in energy use? I limited the horsepower due to availability of the permanent magnet motors which currently stop at 30 HP given a reasonable cost. The percentage of energy saved goes down as the horsepower increases. That is because the higher horsepower premium motors you currently specify keep their efficiency at reduced speed. This is one reason the manufacturers have not produced the larger motors.

OK, I Save Energy, But At What Cost?

The sobering fact is that first cost is as important as operational efficiency. The question we at once think about is, what is the payback in years? These ultra-high efficiency motors will cost about 2-1/2 times the price of the current premium efficiency motors. The actual cost will depend on the horsepower, the brand, the construction, the frame, and availability. I compared two motors of the same manufacturer with similar construction.

The payback runs about 3 years running 365 days

per year and 24 hours per day at the PLEV load profile.

This will be enough to have a conversation with your client about the first cost vs. payback for energy. Obviously, if the pump only runs 6 months, the payback will jump to 6 years. Some may like this opportunity, and some may pass. If your design involves energy saving ideas, this may be one of the options you review.

Thinking About Specifying These PMAC Motors?

I suggest the following if you are thinking about specifications of these motors. First, remember that they are limited in size, speed, and frames available. They cannot be used for all horsepower. I suggest you have both the premium efficiency motors you currently specify and another, PMAC motor specification.

I suggest the following if you are thinking about specifications of these motors. First, remember that they are limited in size, speed, and frames available. They cannot be used for all horsepower. I suggest you have both the premium efficiency motors you currently specify and another, PMAC motor specification.

Because of limited frame options, they may not be available on all styles of pumps. I recommend you work with your B&G representative to check where they can be used. When you want a PMAC motor, name it in the schedule notes. This will tell the construction team which motor you intend to use on which pumps. It is simple and clear.

Also, remember that an ECM motor choice may be available in the smaller sizes.

If you are in Michigan or Northern Ohio, the R. L.Deppmann engineering team stands ready to help you. If you are not so lucky and live somewhere else, call your local B&G representative.

Next week, we will complete this series, and this year, with some special commissioning considerations for the contractors and engineers to be aware of.