Hydronic system pumps and other HVAC and plumbing equipment will often have a variety of motor choices to specify. One of the newer additions to motor options is the permanent magnet AC motor or PMAC. What is a PMAC motor? What is the difference between PMAC and the ECM pump motor? The R. L. Deppmann Monday Morning Minutes finished the year looking at these options.

Hydronic system pumps and other HVAC and plumbing equipment will often have a variety of motor choices to specify. One of the newer additions to motor options is the permanent magnet AC motor or PMAC. What is a PMAC motor? What is the difference between PMAC and the ECM pump motor? The R. L. Deppmann Monday Morning Minutes finished the year looking at these options.

When talking about motors, it is important to understand there are a variety of uses. The terms, products, and values of motors tend to change with the application. I want to focus today’s blog on motors used in hydronics and clean water plumbing. Some terms are used interchangeably in different industries so the examples I use today are all about, go figure, pumps.

ECM Motors and Pumps

First, both ECM motors and PMAC motors have permanent magnets built into them. ECM is an electronically commutated motor. The motor takes the AC voltage and converts it to DC inside of the motor. There is electronic circuitry which may allow the user to change the speed of the motor manually or automatically. Visit “What is an ECM Pump” for more information.

First, both ECM motors and PMAC motors have permanent magnets built into them. ECM is an electronically commutated motor. The motor takes the AC voltage and converts it to DC inside of the motor. There is electronic circuitry which may allow the user to change the speed of the motor manually or automatically. Visit “What is an ECM Pump” for more information.

The ECM technology can be incorporated into a pump. This does not make the pump a “Smart ECM” pump. It is a pump with an ECM motor. Yes, the motor is more efficient. Yes, the speed of the motor, and thus the pump, can be manually adjusted. Yes, the motor may have the ability to take a 0-10Vdc control signal and adjust the speed automatically. A Smart pump has all this and some internal brains to do things on its own. Visit “What are ECM Pumps and ECM Smart Pumps” for more information.

In this article we define the ECM motor as a permanent magnet motor with the electronic circuitry built in to vary the speed of the motor. We start with efficiency.

International Efficiency Standards – a Very Short History

In the 1990s, the United States of America took a leadership position by instituting energy policy standards to improve overall motor efficiencies referred to as EPAct. Our industry was introduced in two steps to the premium efficiency motors which are the standard of HVAC and plumbing specifications in the U.S. today. These standards were only required for motors manufactured or used in the U.S.A. What about the world?

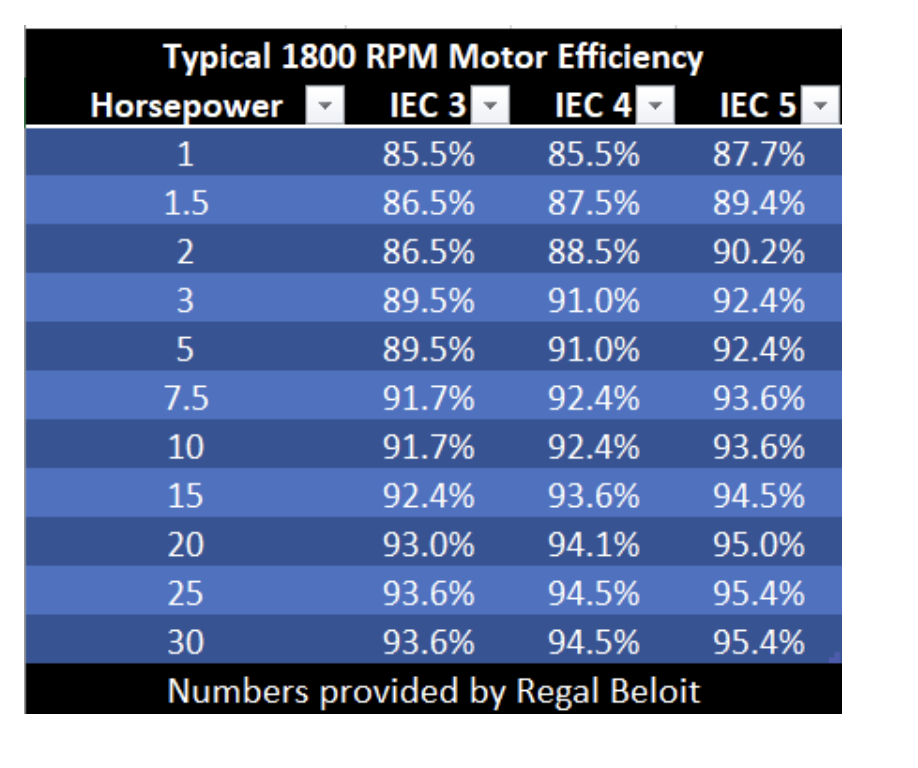

In 2014, the International Electrotechnical Commission(IEC) defined global efficiency classes for motors. That standard isIEC 60034-30-1 2014. Our premium efficiency motors meet the IE3 classification.

The IE4 super premium motors are permanent magnet AC motors or PMAC. They may also be some of the ECM motors and pumps. The IE5 Ultra-premium motors are mostly ECM motors.

The current requirement for motors is the IE3 efficiencies. We see that the IE4 PMAC motors will increase the full load and full speed efficiencies by 1-2%. The ECM motors will trump the PMAC motors by another 1% or so.

How Does a PMAC Motor Differ from the Epact Premium Efficiency Motors?

The motors you normally specify on pumps are Asynchronous induction AC motors. This means that the full speed of the motor is slightly less than the nominal speed. The motor uses a little of the AC power to create the magnetic field. An 1800 RPM premium efficiency motor’s full load speed “slips” and could be around 1765 RPM. This reduces the motor’s efficiency.

A permanent magnet motor is just that. It has a magnet in it and is always ready to start. No power is needed to create and maintain the magnetic field. This improves efficiency and makes the motor synchronous. The 1800 RPM motor can run at 1800 RPM. The rotor turns at the same speed of the changing magnetic field of the stator. There is no “slip”.

This synchronous operation supplies more torque at low speeds. This high torque is important in conveyer belts but of little value in hydronic pumps which are variable torque devices. What this does give you is lower motor temperatures. The motor runs much cooler than our traditional AC motors.

How Does a PMAC Motor Differ from the ECM Motors?

The ECM motors have electronics in them that allows you to change the speed manually or automatically. A PMAC motor requires a variable frequency drive (VFD). The PMAC motor cannot work without a VFD. Our industry uses VFDs on most applications, so this is not a major change.

The ECM motors have electronics in them that allows you to change the speed manually or automatically. A PMAC motor requires a variable frequency drive (VFD). The PMAC motor cannot work without a VFD. Our industry uses VFDs on most applications, so this is not a major change.

The drive is needed to change the speed of the pump motor to control the flow rate or pressure differential. In a PMAC motor, the VFD is also needed to set the motor to its rated speed. The premium efficiency asynchronous 10 HP motor you currently specify operates at 60 Hz at the nameplate 1765 RPM. A PMAC motor may use 150 Hz to dial the speed into 1800 RPM. I don’t want to get too far into the weeds here. Just know that the PMAC motor needs a drive, and the ECM motor is the drive.

Part of the efficiency advantage of the ECM motor is that the external VFD efficiency also adds to the electrical usage. The ECM motors today are limited to about 10 HP and get expensive above 5 HP. The PMAC motors are available up to 20-30 HP.

A Huge Advantage of PMAC Motors in Hydronic Systems

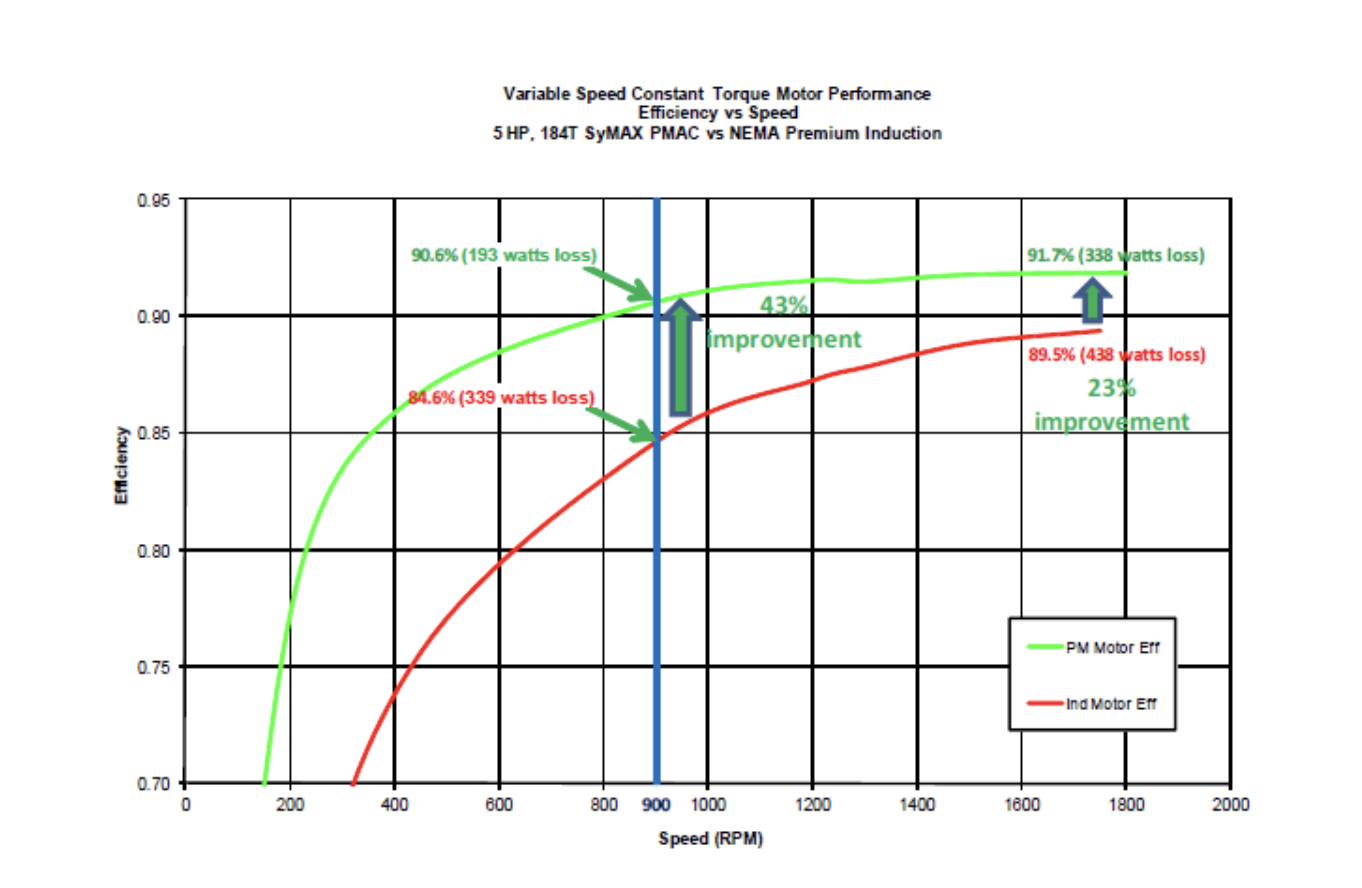

Our friends at Marathon® Motor, Regal Beloit Corp., shared some information about their SyMAX® PMAC motor vs. their premium efficiency motor at part speed. This may interest you more than the couple of percent efficiency increase at full speed. Look at the chart they showed us.

At the full 1765 RPM pump speed, the PMAC motor has a 23% improvement over the premium efficiency motor. When the motor is running at 50% speed, that efficiency improvement becomes 43%!

Hydronic pumps run in the 35% to 75% speed range most of the time. You can see the efficiency increase in the 700 to 1400 RPM range is noticeably big. For example, we have a pump at 250 GPM at 60 feet of head with this 5 HP motor. The PMAC motor will reduce the overall energy of both the pump and motor by over 7%.

When we look at energy saving, our industry also wants to understand the first cost. In Part 2 of this series. We look at costs, startup and selection items, and review the overall advantages and disadvantages of specifying these PMAC motors.