Pumps with ECM or Electronically Commutated Motors have the ability to vary the speed of the pump built into the motor. Can you control the speed to a signal or just set the speed of an ECM smart pump? Let’s find out in this week’s R. L. Deppmann Monday Morning Minutes.

In prior Monday Morning Minutes, we identified that the motors on ECM pumps are more efficient than standard motors. In addition, the motors have an electronic circuit built in that can be used to vary the pump speed.

Using the ECM Pump Motor for Balancing the Flow Rate

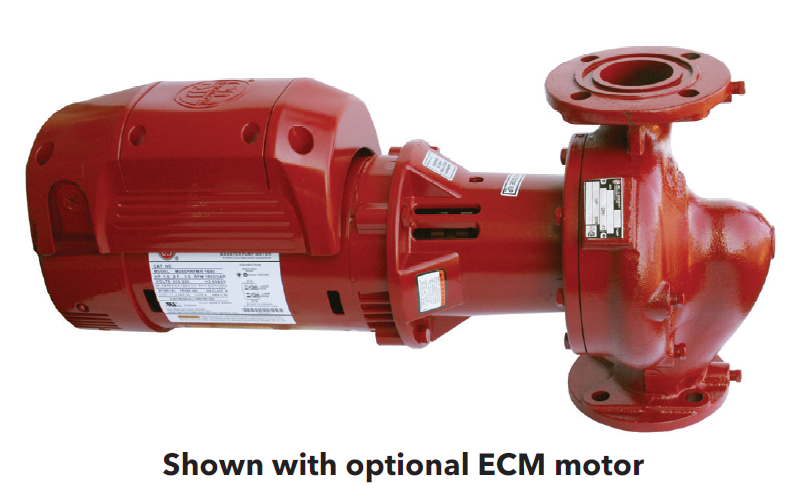

There is a difference between an ECM pump and an ECM “SMART” pump. Let’s use two Bell & Gossett pumps to explain the difference. The image below shows a B&G e60-ECM Inline Pump.

This pump allows you to manually adjust the speed through a potentiometer in the motor. The advantage is that once the pump is installed, the contractor can dial down the over heading or oversizing. This will save energy that would otherwise be wasted across a balance valve. The speed can be adjusted from 300 RPM to the full 1725 RPM.

The speed may also be set through an external 0-10vdc signal. The caution here is that there is no onboard circuitry in the motor to dampen signal fluctuations so if the signal is not steady, the pump life will be shortened.

ECM Smart Pump, Bell & Gossett Ecocirc®-XL, with Various Control Options

The e60-ECM pump is an example of a pump with an ECM motor but no control logic in the pump. There are plenty of reasons to use the e60-ECM pump to save energy but it is limited when it comes to control. An ECM “smart” pump example is the B&G Ecocirc®-XL. This inline pump looks different because it is different. It has an ECM motor for higher efficiency but it also has a vast control logic built into the pump.

Let’s look at some of the ways you can control this Bell & Gossett pump.

- Proportional Control Mode: The pump senses reduced flow and reduce the speed to save energy. (Think variable speed AHU coil pump)

- Constant Pressure Mode: This maintains the pump differential regardless of flow rate. (Think domestic water pressure boosting)

- Constant Speed Curve Mode: This is the traditional trimming of the impeller that ECM pumps do well via speed change.

- Night Mode: This will change the speed at night. (Think night setback)

- T-Constant Control Mode: This will vary the speed of the motor to maintain an internal pump temperature sensor. (Think domestic recirculation)

- ΔT Control Mode: This will vary the speed to maintain a constant differential temperature. (Think snowmelt)

- Analog Input Mode: This will accept a 0-10vdc or 4-20m A signal from your BMS. (Think everything)

In addition, the pump will protect itself against deadhead or no flow conditions so no bypass is needed. It can also link to the BMS system and send all sorts of information about its operation, status, flow, and temperature to name a few. Be careful with the list above. Not all manufacturers have invested the capital to create an ECM Smart Pump with all the controls options that B&G offers.

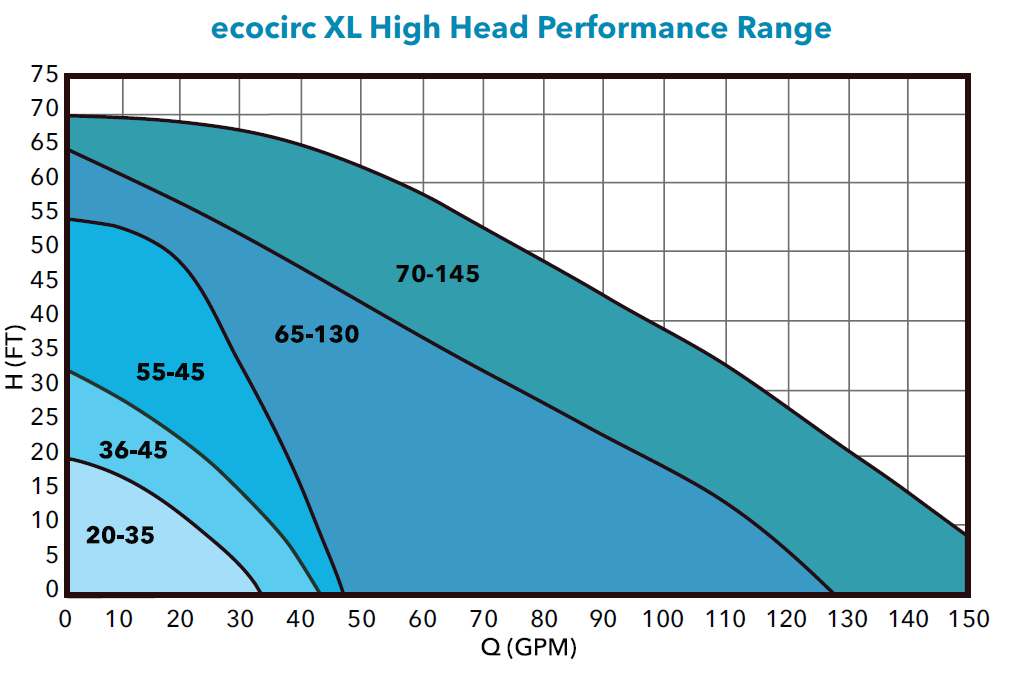

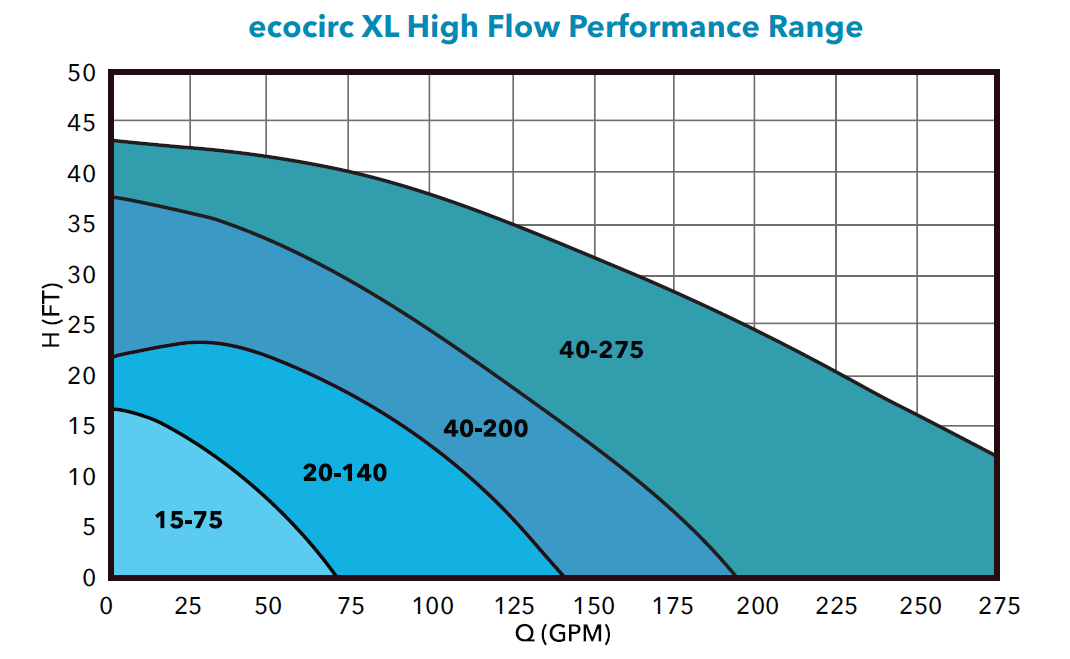

Smart ECM Pumps are Limited in Size

The bad news about these pumps is the limited size range available. The good news is that B&G offers the larger pumps in three phase where many others only offer single phase.