| In our last Monday Morning Minute, we suggested using the Base Mounted Bell and Gossett series 1510 series end suction or VSX series double suction pumps when the design capacity requires over 10 HP. We do occasionally see our series 80 and series 80-SC inline pumps specified in applications up to 100 HP. Often the reason used for this application is limited floor space. Today let’s examine floor space required by these pumps.

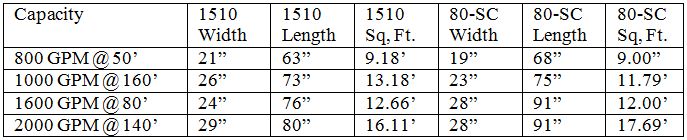

The length of a Bell and Gossett series 80-SC installed pump is a combination of a suction diffuser, the pump, and a long radius elbow on the discharge. Some competitors suggest a combination check, balance, and shut off valve with a spacer between the pump and valve, but that would take up even more space so we will default to the shorter long radius elbow for this example. The width of the series 80-SC is the pump body itself. Many times, the motor will be wider than the pump, but that would be true whether the installed pump was base mounted or inline style. The length of a Bell and Gossett series 1510 installed pump is a combination of a suction diffuser and the pump. The width is the base dimension or pump body, whichever is wider. Based on the Installation Instructions from B&G, I modeled four examples. Here is the floor space required.

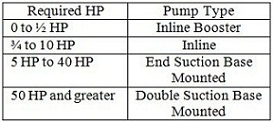

Clearly, space saving is not very significant for the floor mounted inline pump, and in cases where we use our double suction VSX-VSC pump, the space used by the inline style is even greater. Let’s return to the recommendation of R. L. Deppmann Company. A base mounted 1510 has 2 bearings in the motor and 2 bearings in the pump. An inline pump has two bearings in the motor but only a bearing bushing in the pump. A B&G 1510 is easier to service than our series 80-SC or our competitors’ versions. The space required for either is very similar. All of the Bell and Gossett pumps will provide the flow and head shown on the curve. All Bell and Gossett pumps are manufactured to the high quality standards of the Hydraulic Institute, as well as the tighter standards of ITT. There are advantages for your client when you select one pump type over another. We recommend you specify the following:

|

Disclaimer: R. L. Deppmann and it’s affiliates can not be held liable for issues caused by use of the information on this page. While the information comes from many years of experience and can be a valuable tool, it may not take into account special circumstances in your system and we therefore can not take responsibility for actions that result from this information. Please feel free to contact us if you do have any questions.

Archives – Click here for Past Articles