You may experience conversations about the use of magnets in today’s hydronic systems. The need for magnets depends on the pumps you use, the age of the system, and the quality of your air control. Why do you need a strong magnet in a hydronic system? What type of pumps require them? Why are the Detroit Lions so good? Today’s R. L. Deppmann Monday Morning Minutes will answer two of these three questions.

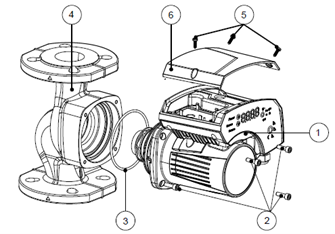

Permanent Magnet Motors and Close Coupled Smart Pumps

Many motors achieve the best efficiency today when the motor contains a permanent magnet. There are motors with a permanent magnet that require a variable frequency drive to operate. There are also electronic commutated motors (ECM) that convert the AC power to DC and can change speeds without a separate variable frequency drive.

Some of the ECM motors attached to pumps are close coupled to the pump impeller. Some are called wet rotors and use hydronic water to cool the motor. This is the case with many of the “ECM Smart Pumps” on the market today. When the fluid is in close contact with the motor, the permanent magnet in the motor will attract metal in the fluid. Bell & Gossett warns in one of their installation, operation, and maintenance manuals, P2002548 Rev F, “A strong magnetic field is created when the rotor is removed from or inserted into the motor housing. This magnetic field can be harmful to pacemaker wearers and others with medical implants. In addition, the magnetic field may attract metal parts to the rotor which can cause injuries and/or damage the bearing of the pump.”

“When using a Smart Pump where the ECM motor is close coupled to the impeller or near the fluid, RLD recommends using a strong magnet in the hydronic system.”

If your “smart pump” motor is separated from the pump by a coupler or an air space and the system is new, the use of a powerful system magnet is less critical. Learn more about best efficiency motors by reading:

- Permanent Magnet Motors & Electronically Commutated Motors

- Permanent Magnet & Electronically Commutated Motors in Hydronic Systems

- The Advantages and Disadvantages of Permanent Magnet Motors

- Smart Variable Speed Centrifugal Pumps: Part 2 (Base Mounted)

Learn more about ECM smart pumps at:

- What are ECM Pumps & ECM Smart Pumps

- What is an ECM Pump? – Part 1

- Variable Speed & ECM Smart Pumps

- Smart ECM Pump Applications – Variable Speed Heating & Cooling System (deppmann.com)

- How Can an ECM Smart Pump Save Energy?

- Smart Variable Speed Centrifugal Pumps: Part 1 (Line Mounted)

Renovations to Older Systems and Magnets

Metal particles and flakes are deadly to mechanical seals. If the metal gets to the seal, it will score the seal and the pump will leak. This may be the cause if there are issues with constant replacement of seals. Visit Hydronic System Centrifugal Pump Basics: Mechanical Seal Failure and Options for more information.

Specify a strong magnet and/or dirt separation when the system is older, and you are renovating or adding to an existing system. This will avoid meetings over equipment issues you inherit in the old system.

What Magnet Do I Specify and Where in the System to Install It?

Here at R. L. Deppmann we represent several options to provide a magnet in a hydronic system. Let’s look at three options in the order of efficiency.

BoilerMagXT for 100% Protection

BoilerMagXT is a full-flow, single-pass insurance against metal in the system. It installs in the 1-1/2” to 12” heating or cooling system main. It is best installed on the return before the system pumps. It is most efficient if installed with 5 pipe diameters upstream. There should be service valves at the inlet and outlet.

The BoilerMagXT is a low pressure drop device. For example, an 8” model BMXT/8 has a pressure drop under one foot when flowing 1100 GPM. Visit Commercial BoilerMag XT – BoilerMag for more information.

Metraflex LPD-Mag-Y Strainer

The Metraflex LPD-Mag Y strainer is a simple solution to full-pass magnet installation. Most systems have Y type strainers at the pump suction. In a new installation, you just use this model at the pump inlet. In an existing installation, you may remove the old strainer and install this in its place. The Metraflex LPD is normally the same size or smaller than other strainers face to face dimension.

There is a great reason to use the LPD strainer even when not requiring a strainer. It is an energy saving device with lower pressure drop than traditional Y strainer designs. Visit New LPD Strainer Design Saves Energy Usage vs Basket Strainers for more information.

Magnet in the Bell & Gossett CRS Separators

Bell & Gossett offers an optional neodymium 45H magnet in their CRS air/dirt separators. This is a low cost optional add when installing a new separator.

We hope this short but specific R. L. Deppmann Monday Morning Minutes will help you choose the right time and place to add a powerful magnet to your hydronic system.