Hydronic and plumbing system pump service is one of the most popular seminars R. L. Deppmann offers for contractors and owners. Questions in these seminars center around pump seals. The failure of the pump seal is normally an indication of another issue in the system. Knowing these issues will help engineers in the selection and operation of centrifugal pumps in building design.

Mechanical Seals in HVAC Pumps

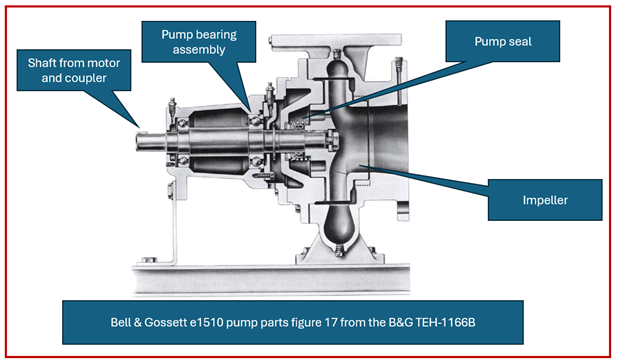

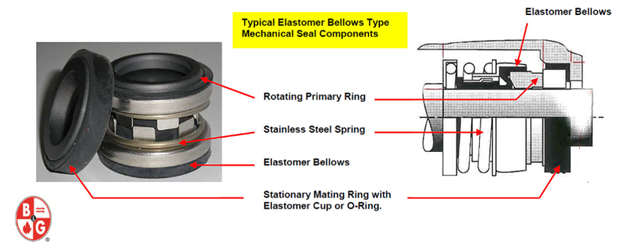

The mechanical seal is the part of the centrifugal pump that keeps the liquid, normally water, from leaking out around the shaft. It consists of a stationary seal surface and a rotating seal surface with a spring to keep the tension on the parts. The parts rotate at the speed of the pump and there is heat buildup potential, so the water helps to cool the seal. It is a work horse part of the pump.

Visit the B&G technical manual for more information on pump parts.

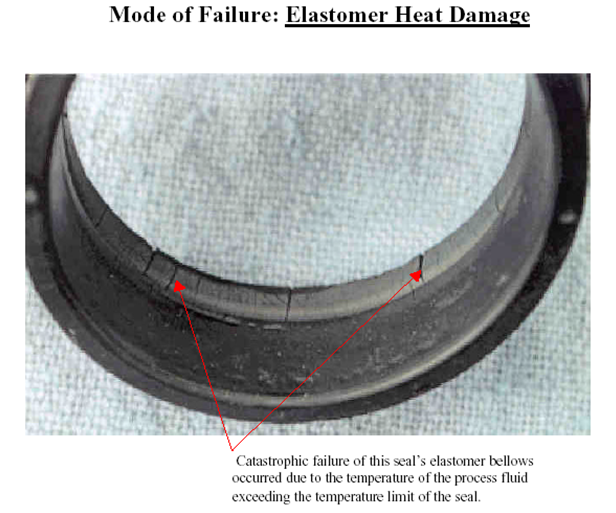

Mechanical Seal Failures Due to Temperature

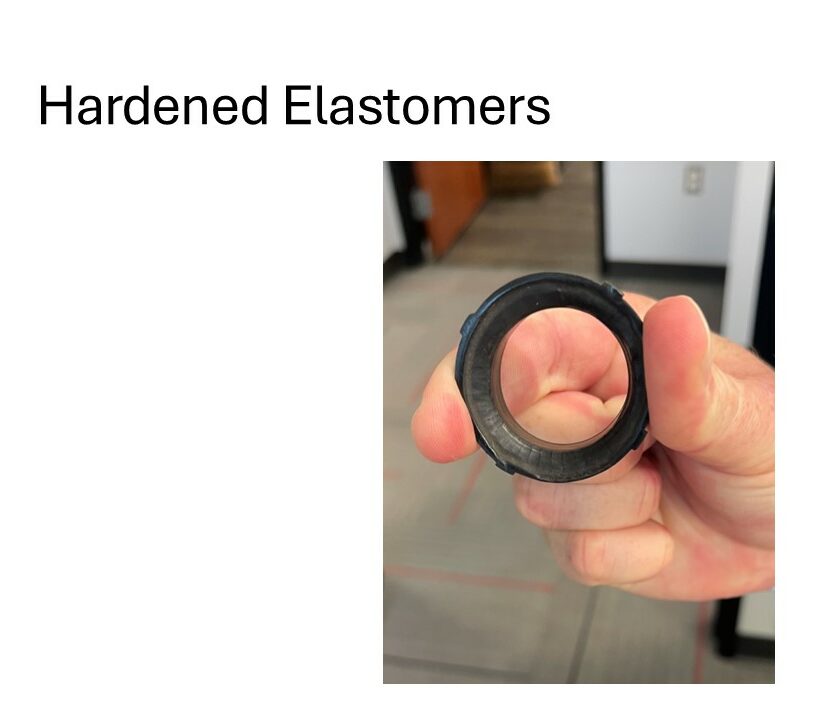

Temperatures outside of the specified range for a given seal construction will quickly damage the mechanical seal. Elevated temperature failures will show up in elastomers. These rubber-like parts will be hard and brittle.

One cause is too high a temperature fluid in the system. Not likely in a building hydronic system. The other places to look is prolonged operation too close to pump shut off or zero GPM.

Another problem may be lack of seal fluid. If there are seal flushing lines, check to see if they are plugged. Internally flushed seals will have less issues and you can read more about that here.

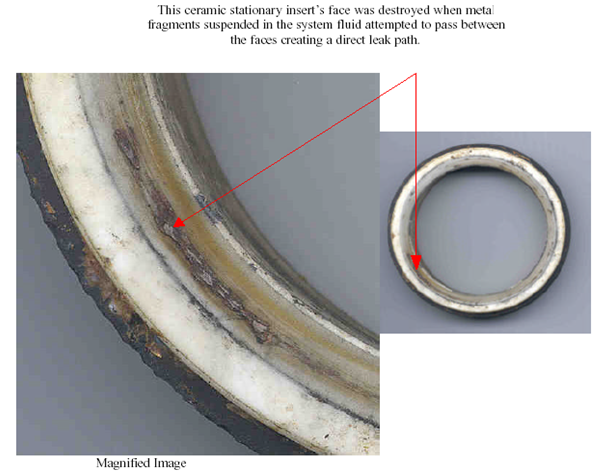

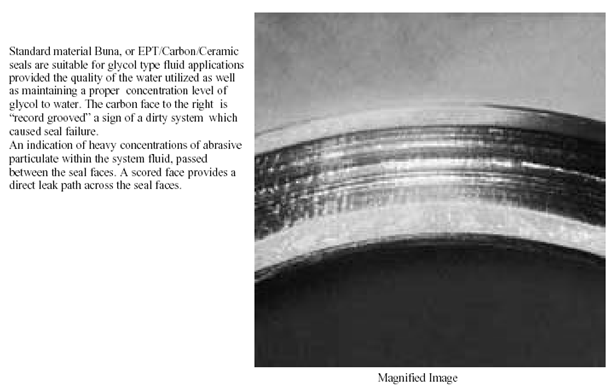

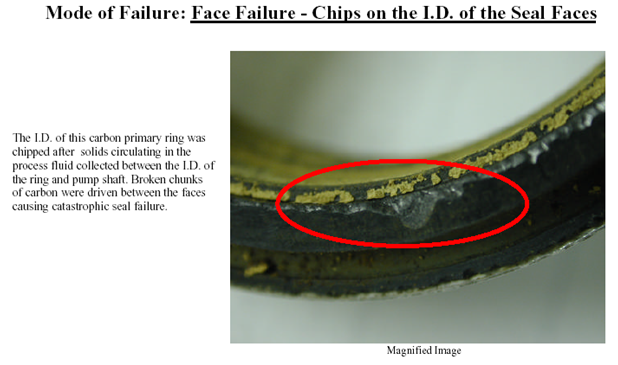

Mechanical Seal Failures Due to Particulate

Particulate in a hydronic system may be dirt, chemical solids from treatment, the higher particulate in glycol solutions, and even small iron deposits from the water or pipe. These solids will score a seal surface quickly. It may be a small circular groove in the seal surface or more of an uneven pit with pieces of the seal gone. The grooved damage will be caused by a general volume of abrasives in the system. The chipped damage is more likely some iron or copper or other larger pieces in the water.

Visit the links shown at the end of this blog for more information.

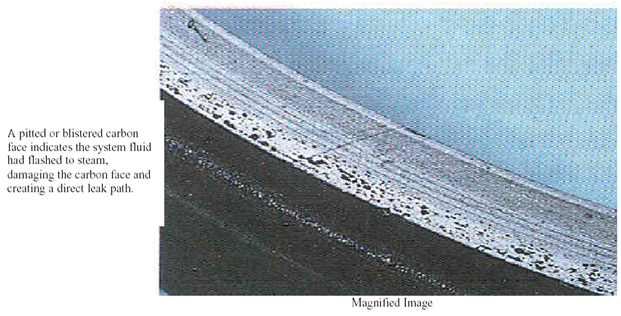

Mechanical Seal Failures Due to Loss of Lubricating Fluids

Pump seals are by nature very tight with little room for water to flow and leak out of the pump. That said, there is water around the seal and at the seal surfaces to lubricate and cool the two seal faces that are spinning against each other at the RPM of the motor. If we lose that lubrication, or lubrication is too low, the seal will fail. This may deal with the issues mentioned above regarding temperature problems.

If there is too little liquid or water available, the heat buildup may cause the water to flash into vapor or steam. This will damage the carbon ring in the seal by blistering or multiple pits. Flashing may also cause chipped edges of the seal.

This flashing may be caused by NPSH issues caused by too much flow for the available pressure.

Mechanical Seal Failures Due to Ph

Seal surfaces and elastomers will be damaged by pumping fluids with a Ph outside of the specified range for the seal materials. Make sure the seal materials are compatible with the fluid chemistry.

Mechanical Seal Failures Due to Poor Alignment

What happens if the rotating and the stationary portion of the seal are not mated perfectly? There may be one or two areas of the seal face that grind down as the seal tries to mate.

These failures may also be an “out of round” seal. One side wears more than the other. These issues could be attributable to improper installation. They are more likely caused by the failure of another component such as bearing damage or impeller damage. It is important to check other parts to make sure you are solving the entire issue.

What Do I Specify?

Standard sealing materials are great for most systems. Deviating and asking for special seals will affect price and availability. It is important to match the seal to the system. Visit our previous blog post for more information.

If you have not had enough about mechanical seals and need something to enhance your knowledge (or just tire you out for bedtime) enjoy the following from R. L. Deppmann Company:

- How Water Quality and Seal Selection Affect Hydronic System Performance

- Pump Mechanical Seal Failures – a Perspective from 1962

- Double Suction Pump Specification: Mechanical Seals

- Bell & Gossett 1510 Pump – Seal Replacement

- Replacing a Seal Kit and Bearing on a VSC Pump