When there is a concern about tower basin sediment build-up, there are several options. Traditionally, valuable maintenance personnel hours may be used shoveling the debris from the tower basin. Today, I offer one solution to significantly reduce that maintenance requirement.

When there is a concern about tower basin sediment build-up, there are several options. Traditionally, valuable maintenance personnel hours may be used shoveling the debris from the tower basin. Today, I offer one solution to significantly reduce that maintenance requirement.

Side Stream Tower Basin Separator Packages

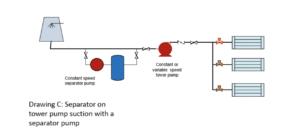

One option for removing sand and sediment from tower basins is to mount a separator so it circulates the tower basin. This side arm circulator will pull the water from the basin and put it through the separator and back to the basin.

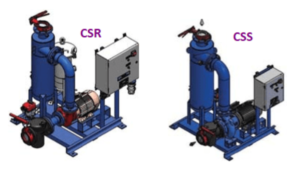

The systems include the pump, valves, and controls. The General Water Systems packages shown here do not use any plastic pipe. They also use a NEMA rated steel or stainless steel panel depending on whether the package is mounted indoors or outside.

The systems may even include a Wave3.1™ chemical-free water treatment system.

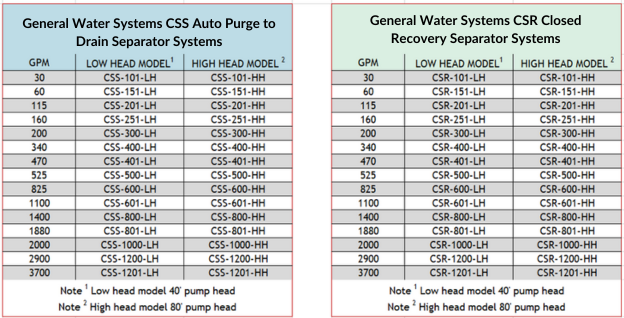

General Water Systems model CSS separator system and model CSR closed recovery separator system. The CSS will blowdown the separator and purge the solids on a timed basis. Open cooling towers must purge water regularly. Because of this we do not recommend the closed recovery CSR model for this application. The CSR system is a great option for closed systems.

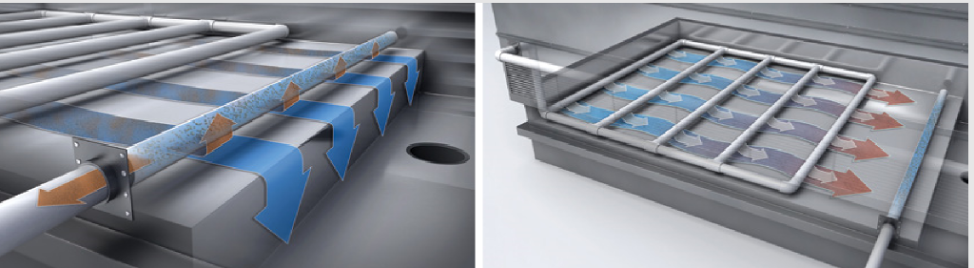

Tower Basin Sweeper System

The separator system is only one part of the effective removal of particulate. The tower basin must have a piping array to pull the heavy sand and debris into the pipe. The OPTIONAL General Water Systems also offers a Sweeper Centrifugal Separator System to achieve the high efficiency required. The traditional system uses a system of nozzles and eductors piped into the basin. The difference between the traditional sweeper system and the General Water Systems is all about energy. The traditional nozzles and eductor system requires a pump with 65 to 80 feet of head. Our Sweeper System operates with a total pump head of 40 feet; Over 35% energy savings!

Selecting the Tower Basin Sediment Separator System

Step 1: Decide whether you wish to use a system with an automatic blowdown to drain (model CSS) or the water conserving recovery system (CSR) Again, on open cooling towers we recommend the CSS model.

Step 2: Multiply the tower flow rate by 10%

Step 3: Multiply the area of the basin without the trough or pump pit times 1.5. This number is the minimum GPM suggested

Step 3: Select a flow rate from the charts below which is at or above the largest of the GPM determined in steps 2 &3

Step 4: Choose the pump head required. If you are using the traditional tower sweeper system with nozzles and eductors, select 80 feet. If you are using the General Water Systems CleanSweep™ basin piping system, use 40 feet. (Both selections allow about 3 feet of friction loss for the piping to and from the tower to the separator system). Contact your representative if more connecting piping friction loss is anticipated.

Step 5: Choose model from chart below

Give Deppmann or your local General Water Systems representative a call to verify selection, provide a detail, and obtain a specification of this great solution for keeping your cooling tower system clean and operating efficiently.

In addition to dirt in the basins, cooling towers may sometimes get a great deal of press when legionella health issues are being discussed. Next R. L. Deppmann Monday Morning Minutes will offer more about open cooling towers.