The sizing and selection of expansion and compression tanks is straightforward when the engineer has the proper information. Today, we list the seven things you need before sizing a tank and offer a sample problem for you to try while reading.

As you read this blog and check out the various links, you will notice a sample problem example. If you want to work along as you read, visit Expansion & Compression Tanks in Hydronic Systems: Take a Quiz . The steps below will result in the numbers needed in the expansion tank formula.

Step 1: Identify the System Fluid

Different fluids have different properties at different temperatures. It is important to note the type of fluid. Will the system have water or glycol? If glycol, is it propylene or ethylene and at what percentage?

Step 2: The System Fill Pressure at the Tank

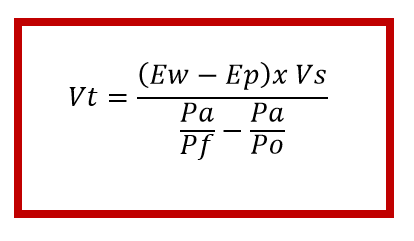

The expansion tank will control the pressure and keep it from exceeding the design maximum pressure the engineer chooses. We must know what pressure we start at. Visit our previous R. L. Deppmann Monday Morning Minutes, Expansion & Compression Tanks in Hydronic Systems: Initial or Cold Fill Pressure, for more on this topic.

Step 3: The System Final Pressure Required

The next item needed is the maximum pressure your design would allow at the expansion tank. Visit our previous R. L. Deppmann Monday Morning Minutes, Expansion and Compression Tanks in Hydronic Systems– Part 3, for more on this topic and choosing the maximum pressure.

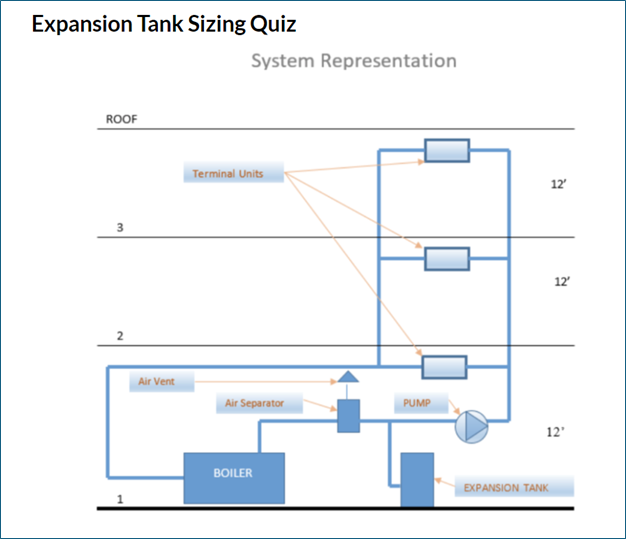

Step 4: The System Volume

The engineer must know the system volume in gallons. This may be a background calculation in your design layout programs, or you may need to do the math yourself. Get the approximate length of each size of pipe, the average volume of coils and terminal units, the volume of your boilers or chillers, the volume of large pieces in the system such as an air separator, and your office standard for any safety factors.

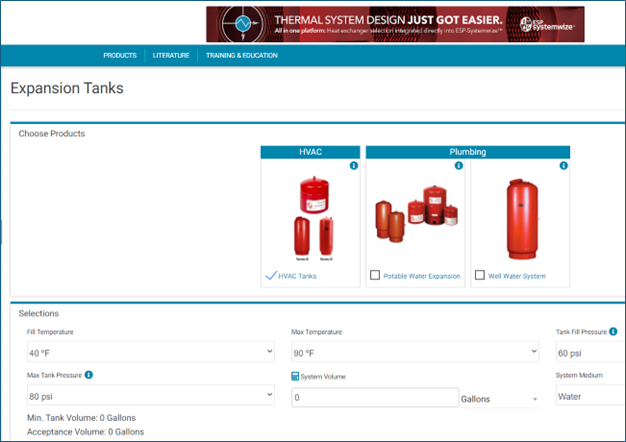

The Bell & Gossett ESP Systemwize program expansion tanks tab has help screens to assist you.

Step 5: The System Starting and Design Temperatures

As the temperatures in the system rise, the pressure will increase. Water will enter the tank and compress the air. We size the tank to make sure it has enough volume to “accept” the water while controlling the pressure. You will need the system volume from step 3 and the starting and final temperatures to calculate the acceptance volume. Visit our previous R. L. Deppmann Monday Morning Minutes, Expansion & Compression Tanks in Hydronic Systems: Acceptance Volume, for more on this topic.

Step 6: Compression vs. Expansion Tanks: Choose the Type of System

The terms expansion and compression tank are sometimes used interchangeably in discussions, but they are clearly different. The expansion tank is the tank with a bladder or diaphragm physically separating the liquid from the air. They may be hung or floor mounted. This tank is part of an air elimination system. Visit our previous R. L. Deppmann Monday Morning Minutes, Expansion & Compression Tanks in Hydronic Systems: Air Elimination System, for more about this system and the components needed.

The compression tank is part of an air control system. This tank has liquid and air in the tank with no physical separation between them. It is a proven system that works well but always requires the tank hung above the piping system. Air must travel up from the air separation device to the tank. It is used less frequently today than 30 years ago. Visit our previous R. L. Deppmann Monday Morning Minutes, Expansion & Compression Tanks in Hydronic Systems: Air Control System, for more about this system and the components needed.

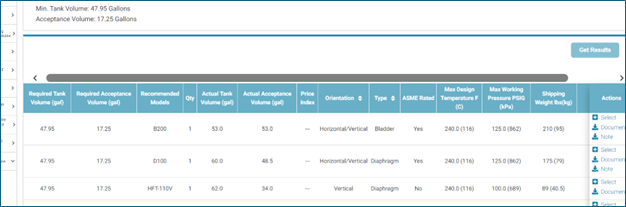

Step 7: Select the Tank Using the B&G esp-Systemwize Program

You have the data required. Now simply choose the type of expansion tank system you want and enter the numbers. The solution is a click away.

You have the knowledge to select your hydronic system expansion or compression tank. If you have further questions or want to double check your work, contact your local B&G representative.