Choosing to use a Bell & Gossett ASME bladder style expansion tank, ASME diaphragm style tank, or ASME standard compression tank in your hydronic system will depend on several factors. Today we look at standard compression tanks used less often today and referred to as an “Air Control System.”

Choosing to use a Bell & Gossett ASME bladder style expansion tank, ASME diaphragm style tank, or ASME standard compression tank in your hydronic system will depend on several factors. Today we look at standard compression tanks used less often today and referred to as an “Air Control System.”

Kyle Wefing, one of our sales representatives, provided a short video on the subject of compression tanks.

Compression Tanks vs Expansion Tanks – What’s the Difference?

Oftentimes the terms are used interchangeably, so you must clarify when someone says “compression tank.” Several decades ago the compression tank was the only game in town for commercial systems using ASME construction.

Compression tanks have no bladder or diaphragm in them. They contain nothing but air. When you fill the hydronic system, the water enters the tank and “compresses” the air. One advantage of applying this tank style is that there are no moving parts to fail or replace.

What is an Air Control System?

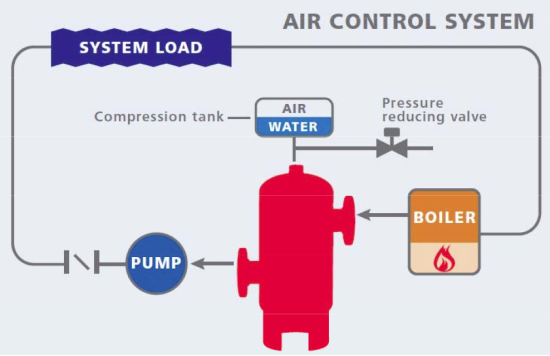

When using a bladder or diaphragm tank we refer to it as an air elimination system. There is an air vent on top of the air separator and we use active automatic air vents in the system. When using a compression tank we refer to the system as an air control system.

The air control system has air in the system. It is in the compression tank. We do not use a main automatic vent off the Rolaritrol. We may have automatic air vents in the system for startup but we close the shutoff valve to the air vents once the air is out of the system.

When Should I Use an Air Control System?

In general, the ASME compression tank costs less than the equivalent ASME bladder or diaphragm tank. The installation cost may be more because the tank must be hung above the air separator. Remember that the total weight is the tank and the water! For this reason you may want to use these tanks when the bladder or diaphragm tank is one of the smaller sizes.

There is a startup procedure to properly set the tank level. For this reason, if the system will be opened regularly, you may want to stay with a pre-charged expansion tank.

Installation of Compression Tanks

The key points in the installation of a compression tank are simple:

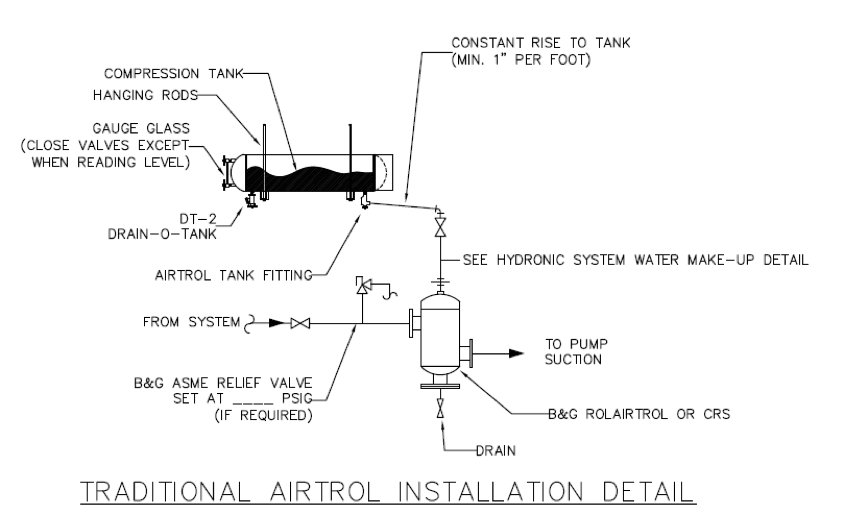

- The bottom of the tank must be installed above the connection to the system. There must be a continuous rise for the air to move from the system to the tank.

- There should be an air removal device in the system to provide a motive force to separate the air and move it into the tank. Larger systems would use a Bell & Gossett Rolairtrol (R or RL) or Coalescing Removal (CRS) separator.

- Use a Bell & Gossett Airtrol Tank Fitting (ATF and ATFL) at the tank to set the starting water level in the tank and prevent gravity circulation between the system and tank.

Next week, the R. L. Deppmann Monday Morning Minutes will continue with a look at the air elimination system.