Bell & Gossett (B&G) provides a simple to use program for the sizing of expansion tanks. The engineer determines the input and enters the numbers. …

Sizing Expansion and Compression Tanks

The sizing and selection of expansion and compression tanks is straightforward when the engineer has the proper information. Today, we list the seven things you …

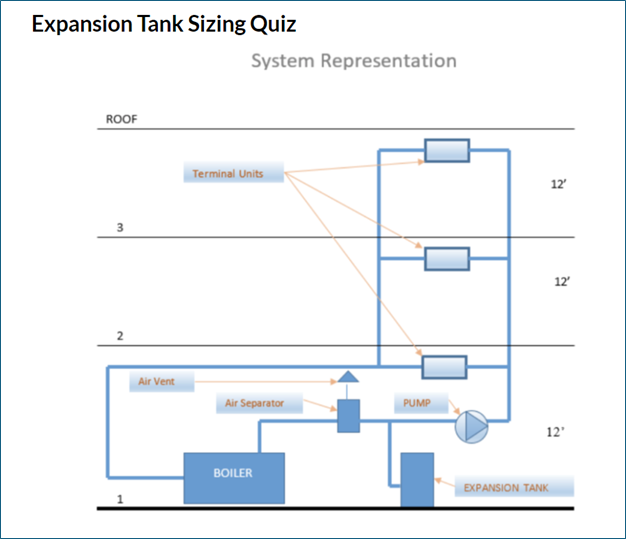

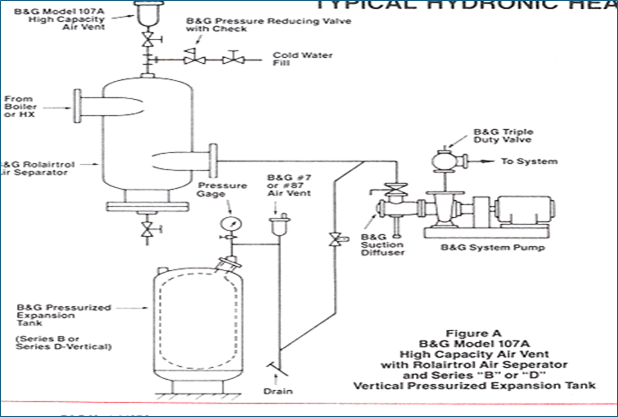

The Purpose of Expansion and Compression Tanks

The expansion tank is a critical component in the closed system hydronic heating and cooling design. The sizing and location of the expansion tank is …

Existing Hydronic System Volume Calculations

During a recent visit to a K-12 school hydronic system, I was asked if there was a way to determine the total system volume. My tongue …

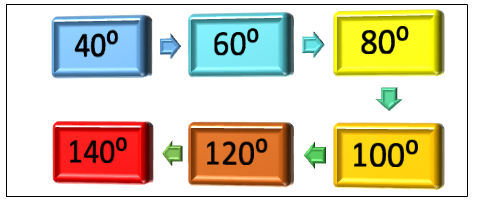

Heat Pump Water Heaters: Temperatures & Storage (Part 4)

Commercial heat pump water heaters using R-744 (CO2) refrigerant operate best when attention is paid to the piping and storage tank arrangement. Today, in part …

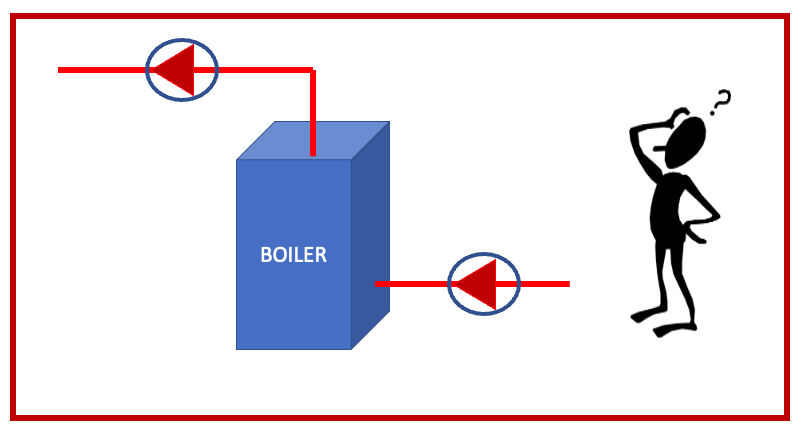

Primary Variable Heating Systems: Should I Pump Into the Boiler or Out of It?

We recently received several calls for our recommendation on whether to pump into the boiler or out of the boiler in a primary variable heating …