Printer Friendly (PDF)

Bell & Gossett (B&G) provides a simple to use program for the sizing of expansion tanks. The engineer determines the input and enters the numbers. B&G outputs the tank volume and acceptance volume. One more key stroke and the tank selection, specification, and dimensions are all yours. Today, we offer a quick video showing how to use the program.

Expansion Tank Sizing Input Data

In the last R. L. Deppmann Monday Morning Minutes, Sizing Expansion and Compression Tanks, we offered the steps to follow to gather the input required.

In the video we offer today, there is a four-story building with a hydronic heating boiler on the main floor. Here is the input we use in the example video:

-

-

- Fluid: The fluid is 40% propylene glycol.

- Fill Pressure: The cold fill pressure is 25 PSIG. This gives us 4 PSIG at the top of the system before heating.

- Maximum Pressure: We used 75 PSIG in the video.

- System Volume: We used 1,200 gallons.

- Starting Temperature: It can get cold here in Michigan in the winter. We assume 40⁰F.

- Final Temperature: The system has a 40⁰F delta T from 140 to 180⁰F. We used 180⁰F and not the average of 160⁰F. We explained in the video.

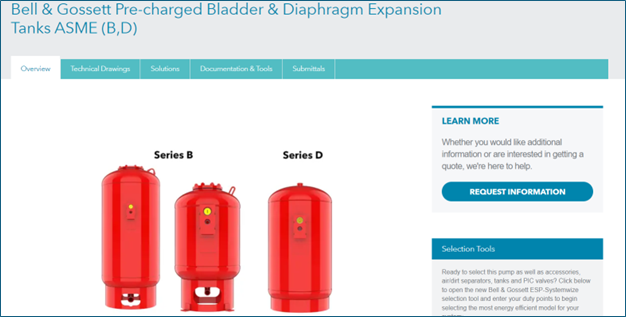

- Type of Tank: We chose to use a pressurized expansion tank.

-

Hope you enjoyed this series on expansion tank sizing in hydronic systems.