The expansion tank is a critical component in the closed system hydronic heating and cooling design. The sizing and location of the expansion tank is critical to proper operation of the system.

Open and Closed Systems

We start this subject by making sure the reader understands the difference between open and closed hydronic systems. An open system is one where, somewhere in the piping, there is an opening to the atmosphere. If you hook up a garden hose to the system and turn on the hose, eventually water will overflow. An evaporative cooling tower is a perfect example of that type of system. The tower clip shown above is from a brand we represent, Tower Tech.

If the tower is off and the pumps are off and you hook a garden hose to the system, water will fill the tower basin and overflow. This is an open system. Most plumbing systems are also open.

A closed system is one where there is no place where the system is constantly open to the atmosphere. If I pressurize a closed system with a garden hose, water will enter the system until the pressure in the system is the same as the water pressure in the hose. Water will stop flowing if the hose pressure does not open the safety pressure relief valve. We realize this is simple, but it is important. All closed hydronic heating and cooling systems require an expansion tank.

The Purpose of the Expansion or Compression Tank

Water is incompressible. As we heat water, it will try to expand. In a closed hydronic system, the entire system piping is filled with water. Since there is no place for the water to expand, the pressure will increase as we heat the water.

It will not take much heat before the pressure exceeds the safe working pressure of the system components and something may break, or a safety relief valve will open. Neither of these options are normal operating conditions.

Fill a pot to the very brim with water and start to heat it. Eventually the cover will lift, and the water will drip down the sides. Water is incompressible.

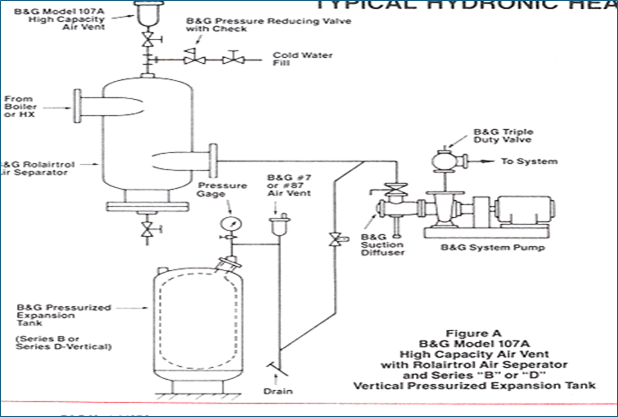

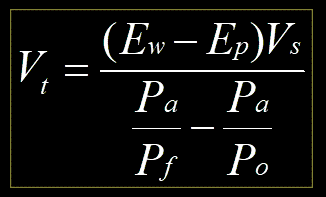

The expansion tank is the one place in the system where there is air. As we heat the water, The water volume in the tank increases and the air volume in the tank reduces causing the air pressure to rise. Although this blog won’t get too detailed, we did want to share the equation above. This Boyle’s Perfect Gas Law. This formula is used to calculate the air volume required in the tank to manage the pressure increase. We can do this using this equation or by using a program. The size of the expansion tank in a hydronic system is a function of the temperature in the system and the starting and maximum pressure we allow.

We have the Bell & Gossett ESP Systemwize program to do the work of calculating the right tank. All you need is the volume of water, the starting pressure in the system, the maximum pressure the system can manage, the starting temperature of the water (or liquid), and the design temperature of the water (or liquid).

Next week we will look at the information you need, provide example systems, and links to learn more about expansion and compression tanks.