Centrifugal pumps find open cooling tower applications are the toughest duty there is in hydronic cooling systems. We are always concerned about the pressure at the pump inlet. We are concerned about air entering the pump. We are concerned about the flow pattern entering the pump. Today we look at the required pressure entering the pump which is NPSHr.

Centrifugal Pump Suction Pressure

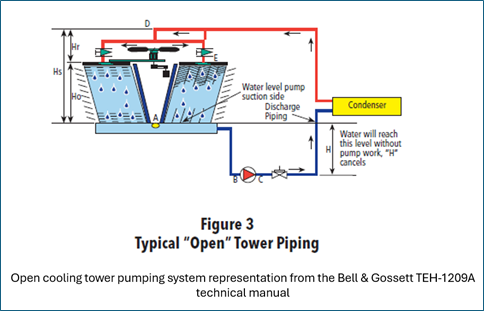

We looked at the cooling tower pump suction pipe size and piping components in our Open Cooling Tower Pump Suction Piping Part 1. The static pressure at the pump suction is the elevation of the water in the open tower pan above the pump inlet. The pressure is reduced by friction through the components when the pump is flowing water. The pressure will drop down and may even become a vacuum on a pressure gauge.

Just because a pump is seeing a vacuum at its suction does not mean it is in trouble. How negative can the gauge pressure be until the pump is in trouble? Read on!

Minimum Suction Pressure or NPSH

NPSH or net positive suction head is a pump term. It is the amount of absolute pressure, expressed in feet of water, required at the pump inlet to avoid damage to the pump. The pump manufacturer will tell you what that required NPSH is for any GPM on the pump curve.

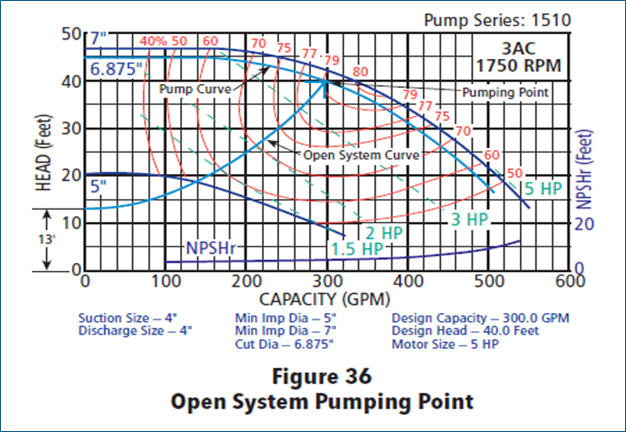

Look at the pump curve published in the B&G Training Manuals cooling tower manual. The curve at the very bottom is NPSHr or net positive suction pressure required. You read from the GPM up to the curve and then read the NPSHr to the right on the curve. Example: Look near the end of the curve at 500 GPM. Read up to the NPSHr curve and to the right. The answer is about 10 feet of absolute pressure.

You look at a compound gauge on the pump suction, and it reads 10” Hg which is a big vacuum. Are you in trouble with the pump above? Well 10” Hg is 23 feet of absolute pressure at sea level. You have way more than the 10‘ required by the pump.

More About NPSH in Past R.L. Deppmann Monday Morning Minutes

Net positive suction pressure is important. We have written a lot about this subject. Look at the articles below. They will help you understand this subject.

- Net Positive Suction Head (NPSH): Terms and Definitions

- Net Positive Suction Head (NPSH): Safety Factors

- Net Positive Suction Head (NPSH): NPSH Available

- Net Positive Suction Head (NPSH): Gauge Readings

- Net Positive Suction Head: Good Cooling Tower Pump Piping Practice

When you get into large cooling tower pumps over 100 HP, the NPSH safety factor may change. This article introduces this very advanced topic.

- Pump Suction Energy Levels in Hydronic Pump Piping and Trim

- Where Cavitation Begins – Cooling Tower Pumps and Piping

Quiz Examples on NPSH

Try and answer this example quiz question. We will provide the answer next week.

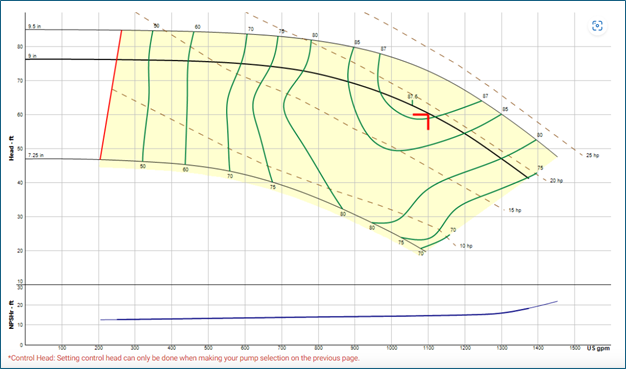

Example open cooling tower pump. You have a single open cooling tower and require a pump for 1100 GPM at 60 feet. This is a constant flow application, so you select a constant speed pump shown above. The pump is a B&G e1510-5BD with a 6” suction size. The tower water level is only 2 feet above the inlet of the pump. You select 8” steel pipe for the suction pipe size.

The project is in Jackson, Michigan and the elevation of the project is 1,000 feet above sea level. The tower is outside with an 8” outlet and a design temperature of 85⁰F. The pump is inside with a suction pipe length of 30 feet including the tower outlet pipe.

There are 4 short radius elbows in the pipe and a butterfly service valve.

There is a basket strainer with 1.0 PSIG pressure drop at 1100 GPM. You want to allow for fouling before cleaning so you will use 2.0 PSIG pressure drop in your calculations. Can you answer these five questions? HINT: We strongly recommend you use the B&G electronic system szyer on a computer rather than your mobile device. System Syzer

- What is the NPSH required by the pump? Do not forget the safety factor of 1.5 suggested in the blog link above.

- What is the velocity in the suction pipe in FPS?

- What is the pressure drop in the piping at 1100 GPM? HINT: Use the “Help with total equivalent length (T.E.L.)” button on the Length/Pressure Drop tab.

- What is the NPSH available to the pump? Do not forget the elevation.

- Can you use this pump in this application?

Next week we will look at swirling concerns at the pump suction and answer the quiz question from today.