I frown a bit when reading about a product and the only place you find a key tip to avoiding problems is in the troubleshooting guide of the instructions. How do you handle a statement like, “If the product is not working properly, make sure it is installed this way!”? Many installations in hydronic closed systems do not meet the exact word-for-word installation requirements in the manufacturer’s IOM, yet they still work fine. Is there any way to identify which pump may have problems? One signal may be the energy level of the pump. As the pump suction energy level increases, the chance of pump problems due to incorrect piping also increases.

I frown a bit when reading about a product and the only place you find a key tip to avoiding problems is in the troubleshooting guide of the instructions. How do you handle a statement like, “If the product is not working properly, make sure it is installed this way!”? Many installations in hydronic closed systems do not meet the exact word-for-word installation requirements in the manufacturer’s IOM, yet they still work fine. Is there any way to identify which pump may have problems? One signal may be the energy level of the pump. As the pump suction energy level increases, the chance of pump problems due to incorrect piping also increases.

Most consulting engineers recognize the B&G pump as a major piece of equipment, but it is only one of a large number of major equipment products in a complex building design. So when does the engineer need to pay more attention to pump details? The quick answer is, “always”. But the engineer really wants to pay attention when the pump suction energy level is high or very high. So what is pump suction energy?

Pump Suction Energy Levels: What the HVAC Engineer Needs to Know

The energy level of a pump is a pretty complex subject. If you are designing pumps, you live this every day. If you are designing buildings, when do you need to be concerned? Let’s start by defining what the pump suction energy level is? Pump suction energy is a term used to help predict how much safety factor is needed in NPSH requirements. My simple definition is that it is a numeric indicator of the potential for trouble if the rules are not followed.

- Rules about NPSH available vs. required

- Rules about operation on the pump curve

- Rules about proper suction piping to prevent “swirling” which I mentioned in a recent R. L. Deppmann Monday Morning Minutes article

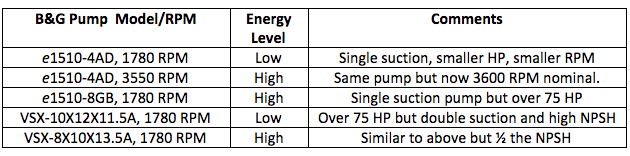

Pump suction energy levels are defined as: low, high, or very high. The reader might guess that the pump energy increases as the flow rate and pump get larger. There are many suggestions I have given over the years for hydronic pump selections and you may remember past articles talking about the following statements. The pump suction energy level increases when you use 3500 RPM pumps instead of 1750 RPM. The pump suction energy level increases when you have large flow capacities and use single suction pumps instead of double suction pumps. One area that may be surprising is the pump suction energy level increases as the NPSH required decreases. When using the pump suction energy level calculations, the NPSHr is the denominator of the formula.

Let’s look at a few B&G pumps along with their suction energy levels.

What Do I Need to Remember in Closed Systems?

“In general, if the pump is 100 HP or more, it is a good idea to ask the representative if there should be any special changes to your standard details.”

Just because you have a larger pump does not mean there is an automatic concern. It’s just a point where the installation and operation will warrant a closer look.