We can conclude the series on waterside economizers with a summary of suggestions for the engineer to consider. ASHRAE 90.1 Energy Standards require this energy-saving design in northern states when the outdoor temperature is below 45°F wet bulb/50°F dry bulb. The engineering team may wish to use this summary and define a company solution to this energy-saving code requirement.

We can conclude the series on waterside economizers with a summary of suggestions for the engineer to consider. ASHRAE 90.1 Energy Standards require this energy-saving design in northern states when the outdoor temperature is below 45°F wet bulb/50°F dry bulb. The engineering team may wish to use this summary and define a company solution to this energy-saving code requirement.

Start with the Code Requirements

The State Energy Codes vary. Some adopt the ASHRAE 90.1 Standard updates quickly while others wait and update less frequently. The State code may follow the ASHRAE wording remarkably close.

Make the Best Engineered Determination of the Winter Chilled Water BTUH Load

- One owner’s building use may not be the same as another. Use the best information available to determine the load requirement when the outdoor conditions drop to a point where the waterside economizer or free cooling heat exchanger is required.

- Too high an estimate will increase both the capital cost and operation cost for the project. Too low an estimate will reduce the capital cost but drastically affect the operational costs by turning on mechanical chillers to supplement the heat exchanger.

Make Sure to Consider the Winter Load When Selecting the Type, Number, and Sizes of the Cooling Towers

- There may be options in the design of the cooling tower, the safe minimum water supply temperature from the tower, flow rates, and the owner maintenance and control. It is best to understand the options before completing the cooling tower system selection.

- Verify the Tower Approach and Range during the winter operation. Read Water Side Economizers Part 3: Cooling Tower Temperatures to learn more.

Select a Minimum Supply Temperature from the Tower

The minimum temperature from the cooling tower will change with the weather. Once the temperature gets closer to freezing, there may be more owner attention or cycling. The minimum temperature you design may be higher than the absolute minimum of the tower. Read Waterside Economizers Part 7: Tower Side Temperatures to learn more.

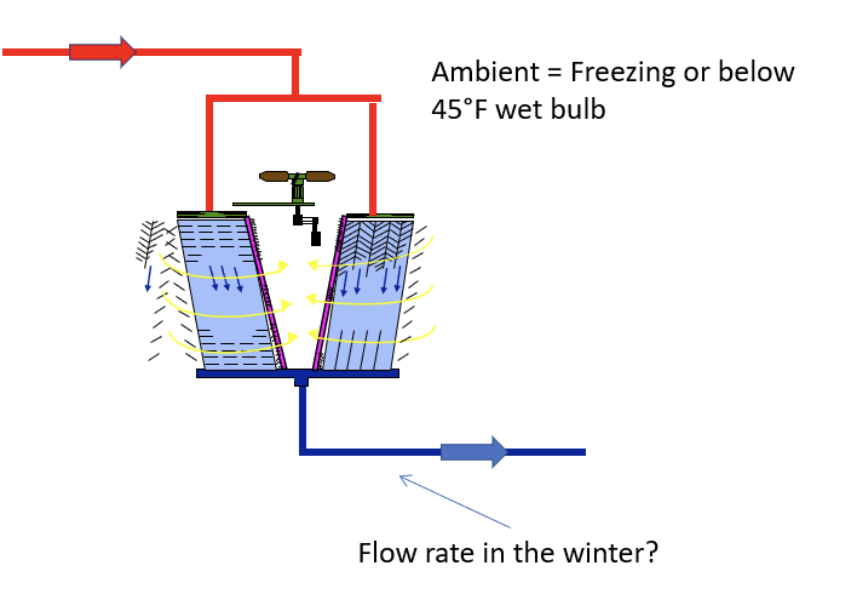

Determine the Winter Operation Flow Rate and Consider Keeping It Constant

- The engineer determined the BTUH winter load when the water side economizer is operational. That load, coupled with the tower range and approach limitations will determine the water supply flow and temperatures from the tower to the heat exchanger.

- Lean toward keeping the flow rate to the heat exchanger constant. Towers may have different minimum flow rates in different winter conditions. Evaluate the gain for changing it vs. the added controls and the effect on the heat exchanger. Read Waterside Economizers Part 6: Tower Side Flow to learn more.

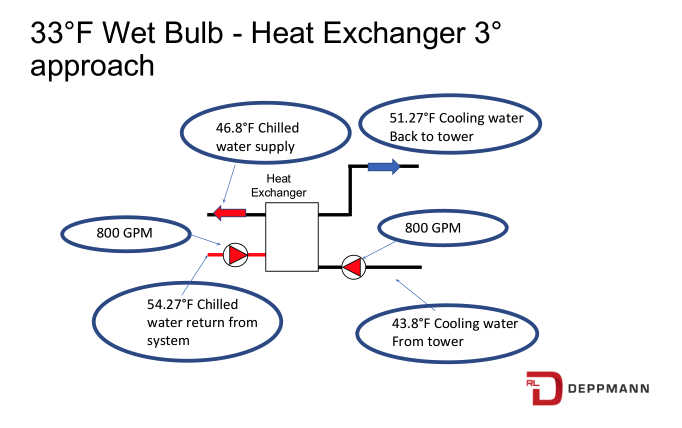

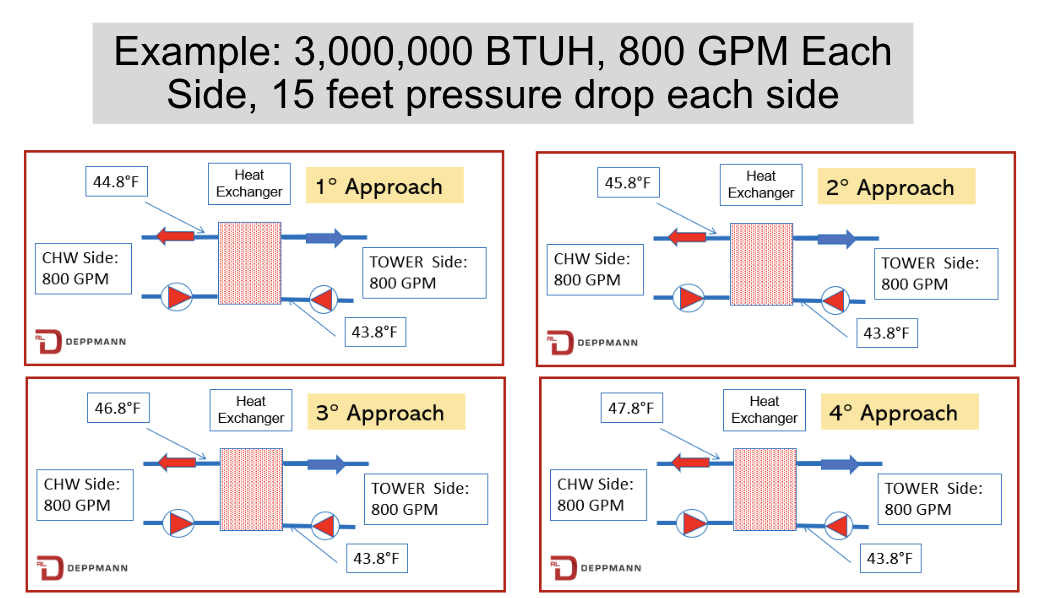

Determine the Chilled Water Supply Temperature from the Heat Exchanger

- The water supply temperature from the heat exchanger to the chilled water system cannot be lower than the supplied tower water temperature. The closer the chilled water supply from the heat exchanger is to the tower supply temperature, the higher the first cost. This is the time to evaluate warmer CHW supply temperatures.

- We suggest never using less than a 2-degree heat exchanger approach. You may want to standardize on a 3-degree approach to allow some comfort in the selection and the initial cost. Read Water Side Economizers Part 8: The Heat Exchanger Approach to learn more.

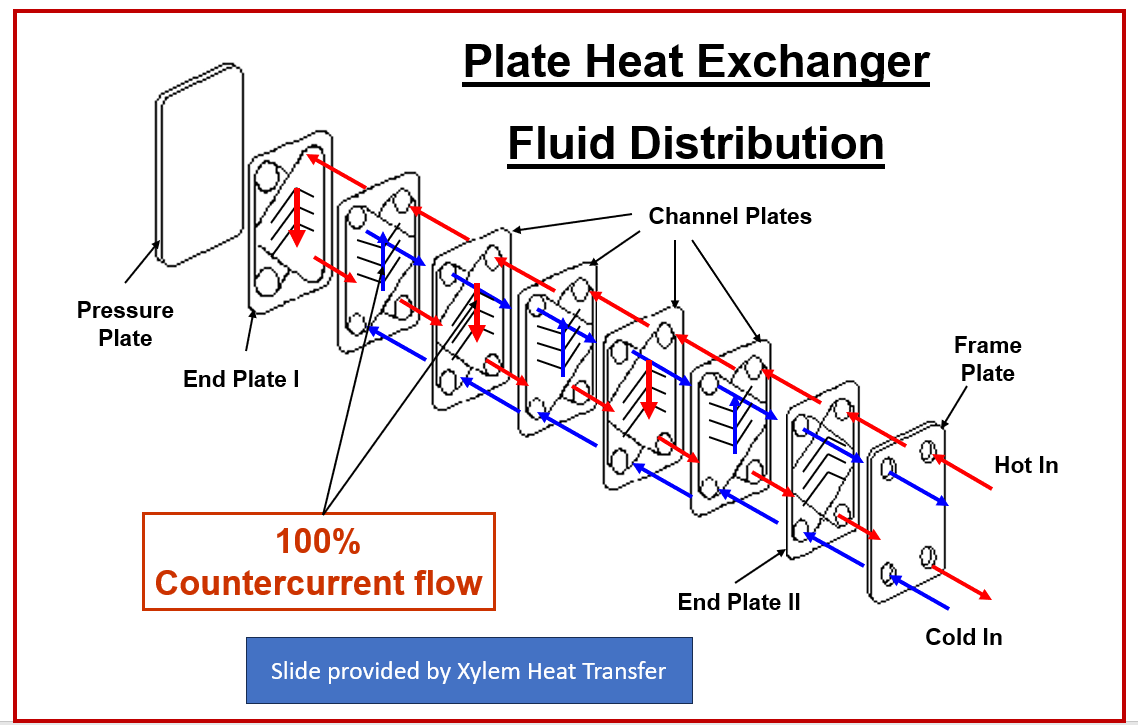

Determine the Heat Exchanger Location and Pressure Drop

- We suggest locating the heat exchanger on the chilled water return to the chiller system. We also suggest a separate pump for the chilled water to the heat exchanger. This reduces the possible fouling, allows for more BTUH when the outdoor temperature is 45 degrees, and reduces the control expense. Read Waterside Economizers Part 5: Heat Exchanger Location Options to learn more.

- There may be some advantage in selecting the heat exchanger chilled water pump and then determining the pressure drop required by the heat exchanger. Getting both from one representative (like Deppmann) will have advantages.

Select the Heat Exchanger and the Trim for Solids and Fouling Management

The owner will appreciate the design that protects the waterside economizer heat exchanger from dirt and fouling. Read Waterside Economizers: Heat Exchanger Fouling & Maintenance to learn more.

In Michigan and Northern Ohio, Start by Contacting the R.L. Deppmann Company

I should have led with this, but you already know this one! Click here to contact us and get started.

We look forward to questions and an opportunity to be part of the discussion with your team.

PART 1: Free Cooling Heat Exchangers

PART 2: State Energy Codes

PART 3: Cooling Tower Temperatures

PART 4: Chilled Water Temperatures

PART 5: Heat Exchanger Location

PART 6: Tower Side Flow Rate

PART 7: Tower Side Temperatures

PART 8: The Heat Exchanger Approach

PART 9: Heat Exchanger Pressure Drop

PART 10: Heat Exchanger Fouling & Maintenance