Waterside economizer heat exchanger fouling can lead to significant operational cost for the owner of the commercial chilled water system. The water side economizer system normally uses a plate heat exchanger with removable plates. The chilly winter water is provided by an open cooling tower. That open cooling tower is subjected to whatever the wind blows in. If the plate heat exchanger is not protected from particulate, the plate will get plugged with whatever the wind blows in.

What is Heat Exchanger Fouling?

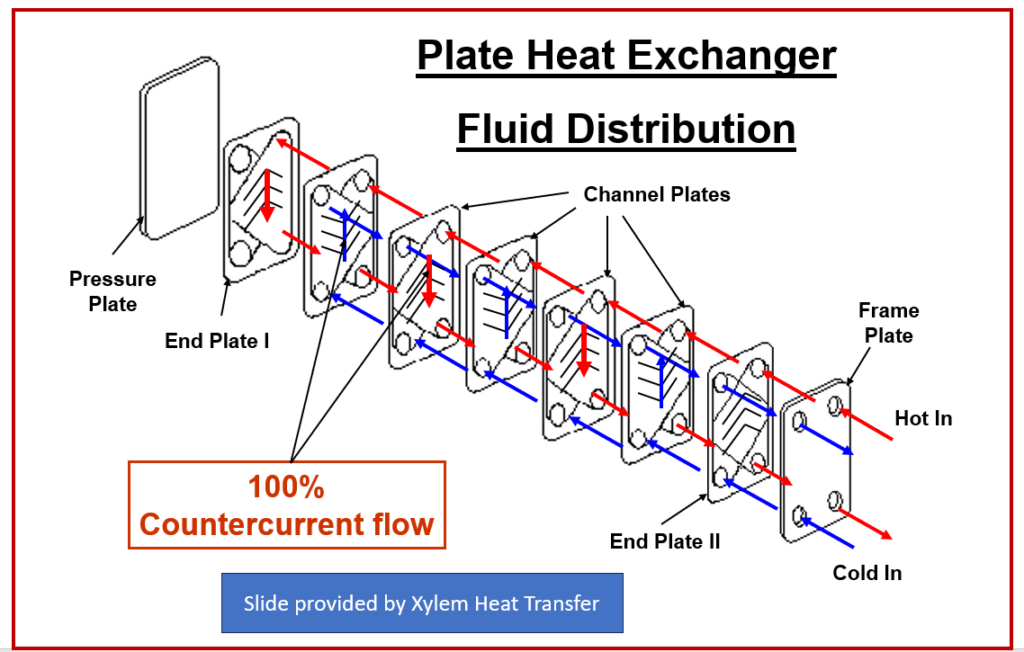

In a plate heat exchanger, the plates are very thin, and the passageways are small. The small passageways allow higher velocities. The higher velocities provide a better “U” value and more BTUH per square foot of heat transfer surface. This is a good thing.

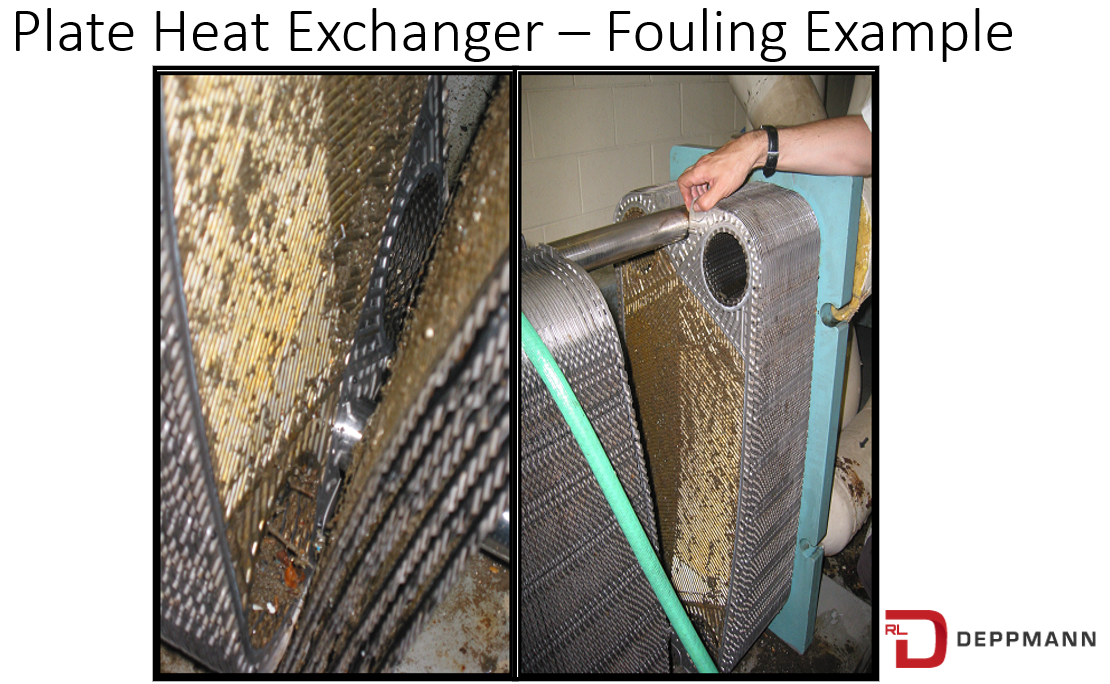

Fouling is a term used for the coating of the heat transfer surfaces. The thin plate offers little resistance to heat transfer. If we add a coat of fouling product, it adds resistance and reduces the heat transfer or output of the exchanger. What can this coating be? Think of the salt or calcium deposits from harder waters; think dirt or sand; think biologicals such as algae. For all of these we might think of a cooling tower. That is the prime source of fouling in a water economizer.

You might ask, “Norm, if I keep the velocity high, will that help.” The answer is yes. The velocity helps scour the plates. Our challenge here is the intermittent operation of the heat exchanger. On and off in the spring and fall based on the weather. The water sits for extended periods. They will foul. The time until the plates foul enough to warrant action is the variable. It will depend on the water quality from the tower or chilled water system.

Another concern is particulate. To understand the issue, we look at the plate channel area.

Plate Heat Exchanger Passageways and Particulate

Plate heat exchangers have small passages. How small is small? The Xylem Bell & Gossett GPX® series of gasketed plate heat exchangers is a commonly specified series for water side economizers. They meet the AHRI requirements resident in most State codes. So, what is the passageway size in this top brand of waterside economizer?

B&G recommends the maximum particulate size in this series. The maximum size varies by model, but the range is 0.043 inches (1.2 mm) to 0.075 inches (1.9 mm).

Just to visualize, that is the thickness of a credit card to the thickness of two credit cards. Not excessively big.

Now think of the spring and fall in Michigan and Ohio. Cottonwood seed pods are 0.1 inches (2.5 mm). The list is large including the ever-flying Locust and maple seeds. If they blow in the wind and the cooling tower is open enough, the heat exchanger will see them.

All of these are large enough to plug a heat exchanger. OK, I have your attention. What do we do about it?

Ways to Reduce the Operational Expense of Water Side Economizer Heat Exchangers

Here are a few examples of ways to reduce the fouling and plugging of heat exchangers. There may be at least two that are new to you.

- Eliminate most of the problems at the cooling tower. This could be a sweeper system, Tower/Condenser Water Systems – Side Stream Separator Systems. It could also be the type of tower. A tower with less drift and side opening. Cooling Tower Design to Save the Planet: Drift Eliminators.

- Add a 20-mesh internal port heat exchanger strainer. Gasketed Plate and Frame Accessories for Heat Exchangers. This strainer can be serviced without disturbing the piping. A simple differential pressure sensor across the constant flow heat exchanger tower connections can alarm when it is time for service.

- Add a sediment separator followed by a strainer on the pumped inlet to the heat exchanger. If the flow rate is constant, these are a terrific way to catch the things that sink and the things that float. Sediment Separators in Variable Flow Cooling Tower Water Systems.

- Select a Xylem Free Flow series of heat exchanger from B&G. The Free-Flow can pass fibrous particles up to 2 mm in diameter and 5 mm long.

-

- This style of heat exchanger will manage larger particles. Depending on the model the maximum recommended particle size jumps to 0.106 inches (2.7 mm) up to 0.226 inches (5.8 mm).

- There is a first cost price for this technology. The cost can jump by 60 to 80% and the lead time will be much longer. That said, if the owner saves a single plate pack replacement, it will pay for itself repeatedly.

Fouling and plugging of water side economizers are a real concern. The engineer has tools to use to fight the battle and save the owner operating expenses.

PART 1: Free Cooling Heat Exchangers

PART 2: State Energy Codes

PART 3: Cooling Tower Temperatures

PART 4: Chilled Water Temperatures

PART 5: Heat Exchanger Location

PART 6: Tower Side Flow Rate

PART 7: Tower Side Temperatures

PART 8: The Heat Exchanger Approach

PART 9: Heat Exchanger Pressure Drop