The last three Monday Morning Minutes have introduced the U.S. Department of Energy 2020 pump standards. The Standard looks at efficiency of pumps equally at various percentages of design GPM. The HVAC and Plumbing engineer know that pumps operate at less than design most of the time, but certainly not in equal percentages.

This article begins a series on a better way to evaluate pump life cycle costs and operating pump efficiency—the part load efficiency value.

When we look at part load operation, the Air-Conditioning, Heating, and Refrigeration Institute provides a good starting point with chillers by providing the AHRI Standard 550/590.

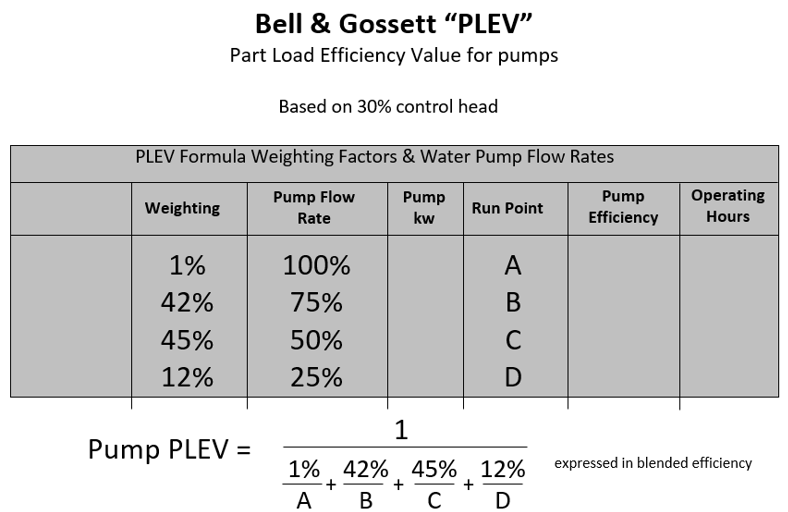

The standard provides a chiller rating, referred to as Integrated Part Load Value (IPLV). This rating is based on the “load” of the chillers. Realizing that this is a standard that engineers are familiar with, Bell and Gossett introduced a new term for the pumping industry: PLEV or part load efficiency value.

Similar to IPLV, this efficiency rating for pumps looks not at part load, but at part flow. It’s different, but relevant and easy to calculate when selecting pumps. PLEV takes a weighted average of the efficiency of a variable speed pump. As the flow rate drops, the speed drops, following a control curve starting at 0 GPM at 30% of the design head in feet.

PLEV weighs the pump efficiency of 100%, flow rate 1% of the time, efficiency at 75% of design flow rate 42% of the time, efficiency at 50% of design flow 45% of the time, and finally efficiency at 25% of design flow rate 12% of the time. The formula is shown below.

Example of Part Load Efficiency Value

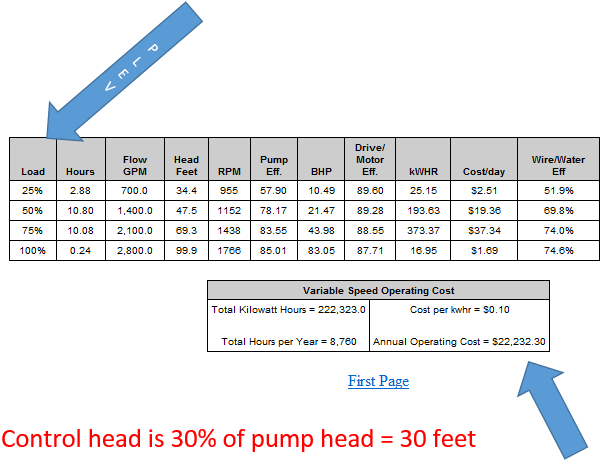

Let’s assume a pump has a capacity of 2800 GPM at 100 feet. We’ve picked our pump and based operating expenses on the PLEV load profile. Our annual operating costs can be calculated as shown in Table 2.

Notice that this calculation is based on 30 feet of control head. Again, it is absolutely critical that we recognize that there will always be some constant head requirement. No pumping system with 2-way valves is ever 100% variable! If we erroneously assume otherwise, then the actual operating cost of our system will not reflect our predictions. In fact, we will have grossly underestimated.

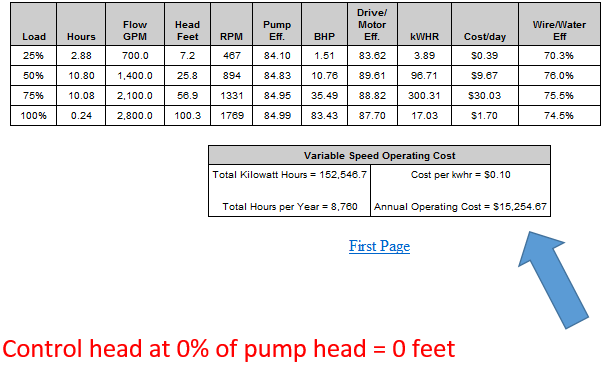

To help illustrate this point, we’ve calculated the annual operating cost for the same system as above, based on zero control head and 100% of variable flow, below. Notice the operating cost is much lower than it was when we had 30 feet of control head — $22,232 vs. $15,254. That’s almost $7,000 missed in operating cost analysis which no one wants.

Using the PLEV as a guide for selecting pumps for today’s variable speed systems is a good way to approximate operating cost and compare efficiencies of different pump selections over a range of operating points. You may replace the control head with the actual value you calculated. If you’re unsure of the exact amount of control head, we recommend plugging in 30 percent of the total pump head for a quick analysis.

Next week we will examine PLEV, its use, and specification options.