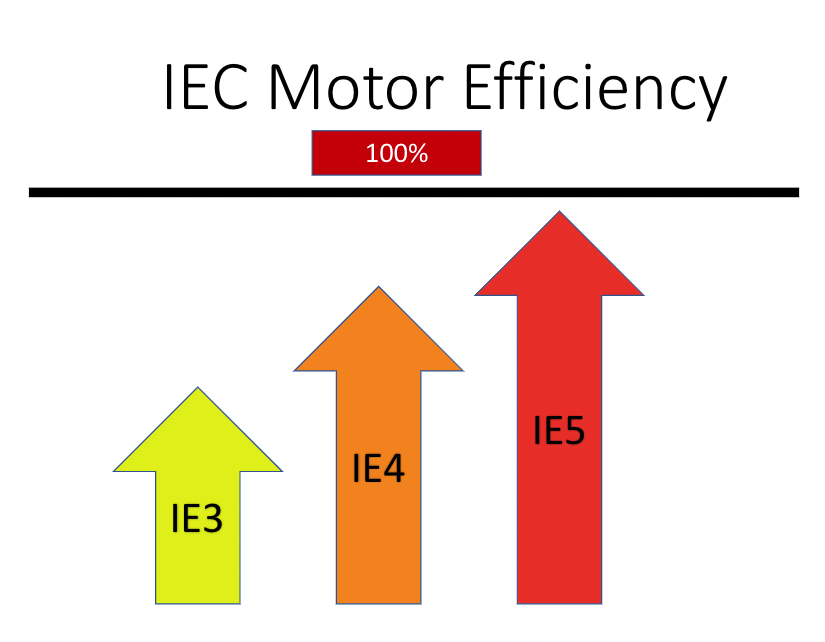

You understand the differences between premium efficiency (IE3) motors and PMAC or ECM motors (IE4&5). You understand the cost implications of both styles of motors. …

Permanent Magnet (PMAC) Motors & Electronically Commutated (ECM) Motors in Hydronic Systems (Part 2 of 3)

Can I and should I specify permanent magnet motors (PMAC) on my hydronic system pumps? The last R. L. Deppmann Monday Morning Minutes showed the …

Permanent Magnet (PMAC) Motors & Electronically Commutated (ECM) Motors in Hydronic Systems (Part 1)

Hydronic system pumps and other HVAC and plumbing equipment will often have a variety of motor choices to specify. One of the newer additions to …

Condensing Boiler Venting Material (Part 1)

Proper venting of hydronic condensing boilers is critical for the safety of occupants and the successful operation of the heating plant. The materials that may …

Hydronic Systems Pump Minimum Flow Methods

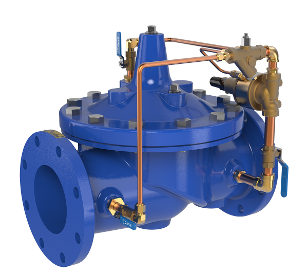

Minimum pump flow rate is critical to the trouble-free operation and longevity of the centrifugal pump. In the last blog we described the use of …

Pump Minimum Flow Using a Cla-Val Back Pressure Valve

Minimum pump flow rate is critical to the trouble-free operation and longevity of the centrifugal pump. The pressure sustaining valve or back pressure valve is …

Flo-Control Gravity Check Valve Replacement

You have a Bell & Gossett Flo-Control valve on the primary secondary bridge of an older hydronic system. It has been there for over five …

Heat Pump Water Heaters: Water Source Units (Part 12)

Many heat pumps used in Ohio and Michigan are water sources for comfort heating and cooling. Today, we want to look at the water source …

Heat Pump Water Heaters: Drive Down First Cost Using Hybrid Solutions (Part 11)

The owner of a local engineering firm recently said to me, “First cost and space are key discussion points in any building design.” First cost …

Heat Pump Water Heaters: Standby Capacity (Part 7)

Hot water availability in many commercial and institutional buildings is critical. Engineers also know that these service water systems are generously sized for the peak …