Minimum pump flow rate is critical to the trouble-free operation and longevity of the centrifugal pump. In the last blog we described the use of …

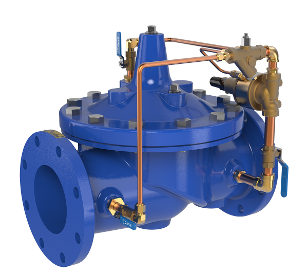

Pump Minimum Flow Using a Cla-Val Back Pressure Valve

Minimum pump flow rate is critical to the trouble-free operation and longevity of the centrifugal pump. The pressure sustaining valve or back pressure valve is …

Pumping From an Atmospheric Tank: Pump and Tank Control (Part 3)

Let me start by wishing everyone a Happy and Prosperous New Year. This blog begins the 14th year of the R. L. Deppmann Monday Morning …

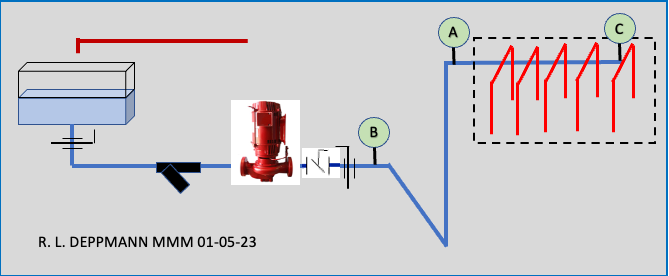

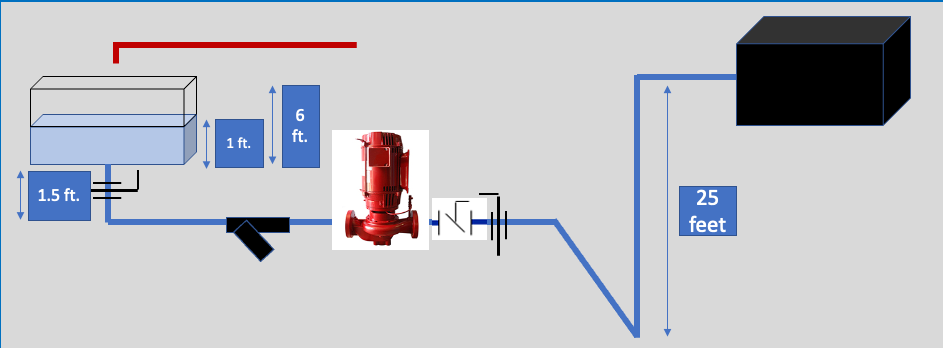

Pumping from an Atmospheric Tank: Pump and Tank Piping (Part 2)

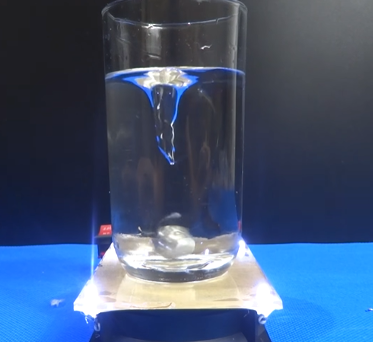

What can be simpler than pumping water from an open or atmospheric tank into another tank or system? What seems simple to many opens a …

Pumping from an Atmospheric Tank: Pump Selection and Installation (Part 1)

What can be simpler than pumping water from an open or atmospheric tank into another tank or system? What seems simple to many opens a …

Commercial Tankless Water Heaters: O2 Trim and Controls

Gas fired water heaters remain the solution for most commercial water heater applications. Tankless gas fired water heaters are the choice of many engineers. Tankless …

Heat Pump Water Heaters: Chilled Water Source (Part 13)

Many heat pumps used in Ohio and Michigan are water source for comfort heating and cooling. Today, we want to look at the opportunity to …

Heat Pump Water Heaters: Water Source Units (Part 12)

Many heat pumps used in Ohio and Michigan are water sources for comfort heating and cooling. Today, we want to look at the water source …

Heat Pump Water Heaters: Example Apartment Building Costs (Part 10)

Your client is interested in a commercial R-744 refrigerant heat pump water heater solution. The example system I used in this blog is an apartment …

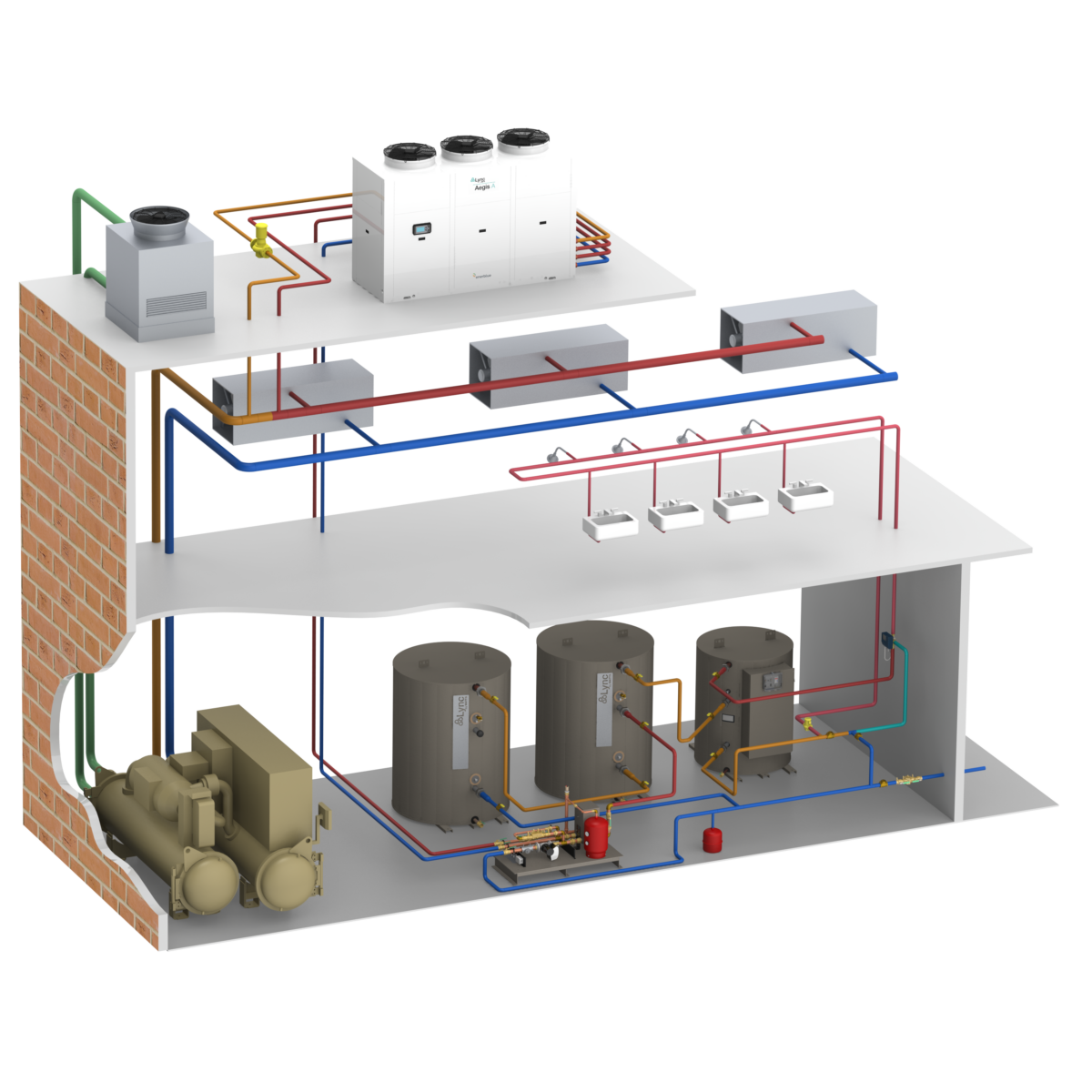

Heat Pump Water Heaters: Example Apartment Building (Part 9)

Air source heat pumps are beginning to get attention in conversations among engineers in the northern climates. I appreciate everyone’s patience as you opened this …