Pressure booster systems used for domestic water may have a single pump or up to 8 pumps operating in parallel and staged to meet the demand. Smaller commercial and institutional systems normally have two, three, or four pumps. How many should you design into your system? It’s all about juggling operating cost, capital cost, and the need for standby pumping capacity.

Pump Efficiency in Multiple Pump Pressure Booster Systems

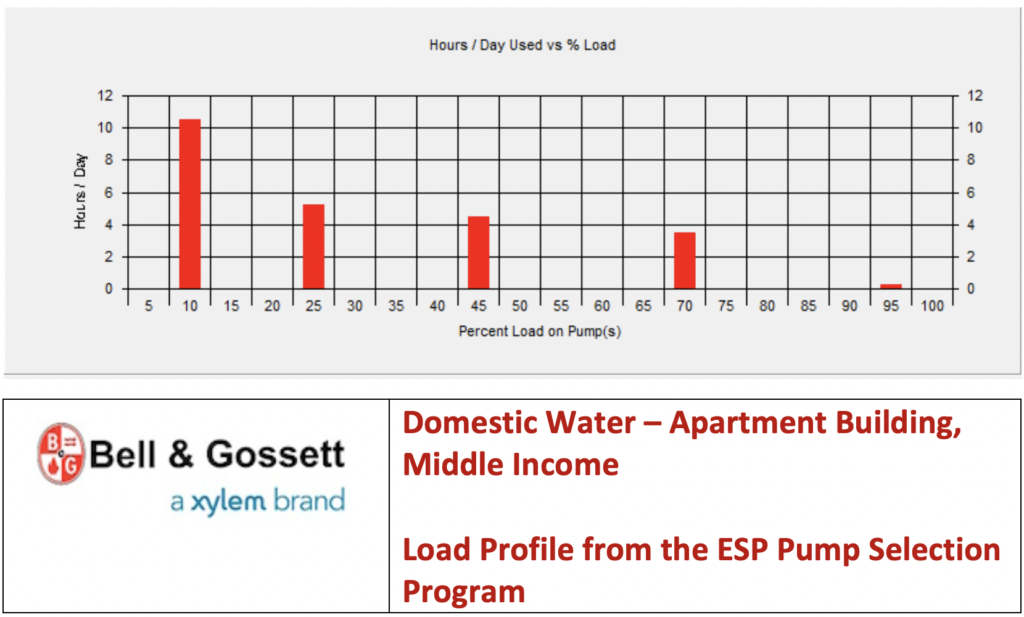

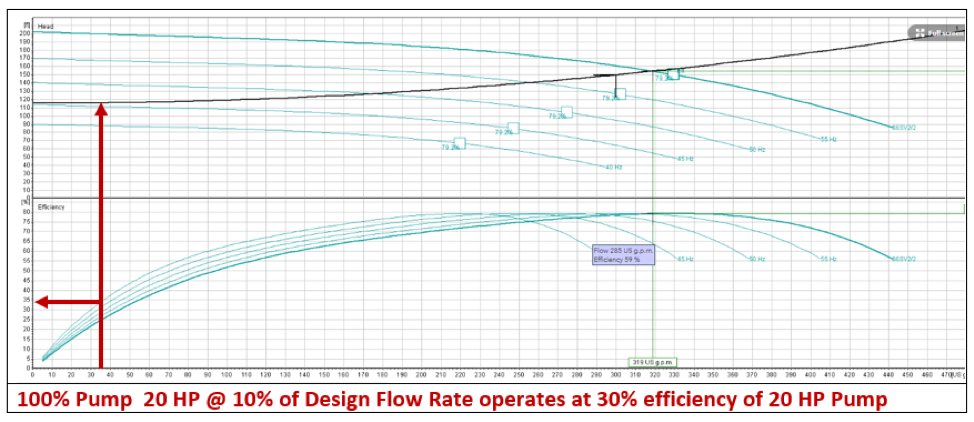

In the last R. L. Deppmann Monday Morning Minutes; Domestic Water “Pressure Booster Pumping System” – Control Head & Curves, I looked at the load profile for an example apartment pressure booster system with a capacity of 300 GPM at a 50 PSIG differential requiring 87 PSIG discharge pressure given 37 PSIG minimum suction pressure. A single 100% pump will operate at 30% efficiency half of the time.

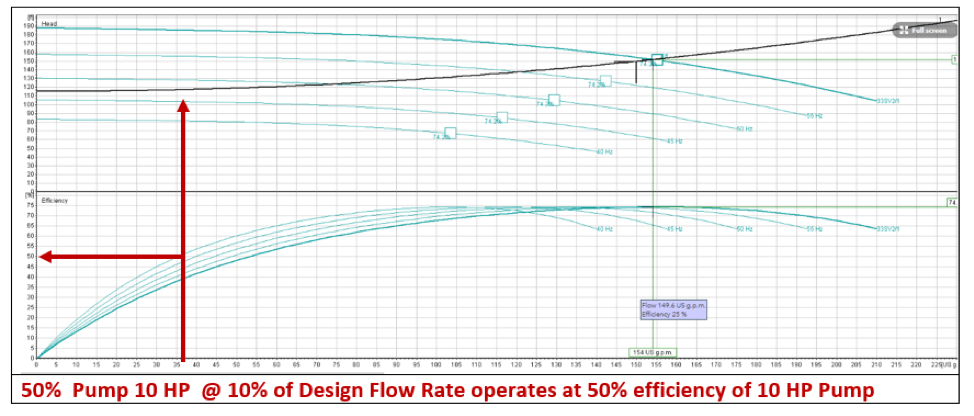

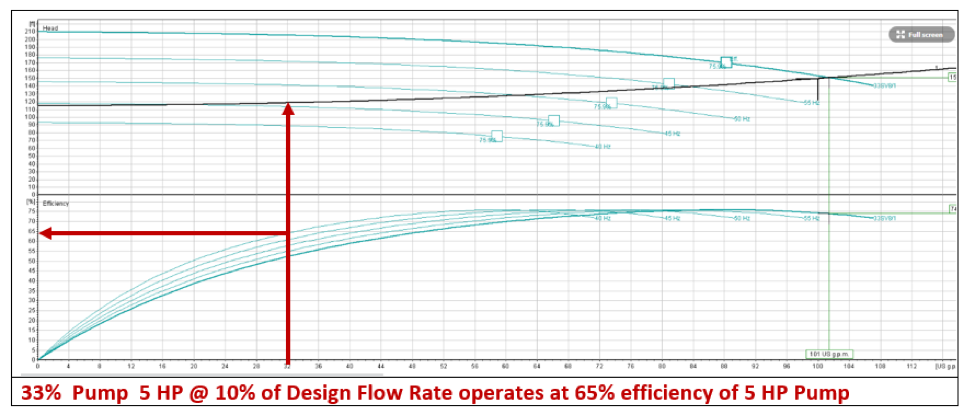

We can see from the load profile that if we use a system with two pumps at 50% flow in parallel (50-50) that only one pump will run most of the time. If we use 3 pumps in parallel at 33% each (33-33-33), we would expect to operate even more efficiently.

Let’s look at some selections and the numbers:

- The first curve below is a 100% – 300 GPM pump.

- The second curve is a 50% – 150 GPM lead pump.

- The third curve is a 33.3% – 100 GPM lead pump.

The arrow shows the same operating point of 10% of the flow or 30 GPM.

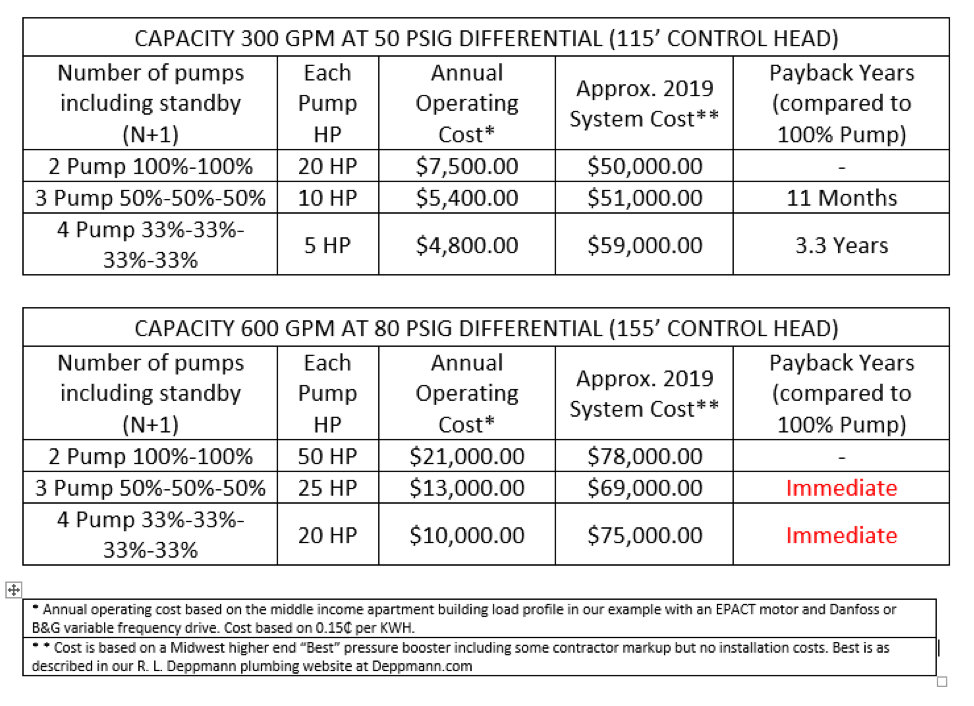

What you may notice is the larger pump is using more horsepower at lower efficiencies. The smaller pump is using less horsepower at higher efficiencies. Using the flow profile for our example problem and staging the smaller pumps will result in less energy use. Here is the table showing the energy consumed. I looked at our example 300 GPM system and a larger 600 GPM system.

In these variable speed pressure boosters, when the municipal water pressure increases, the energy cost decreases. The numbers above do not reflect the varying city water pressure and may affect the results.

If your client will only own the building for a short period of time but requires an (N+1) standby, the 50%-50%-50% is the solution for you. If your client will own the building longer and pay for utilities, the 33%-33%-33%-33% four pump system might be your solution. As the system gets larger, the payback gets better and may even be immediate. What about the cost of the standby pump? Do we need it?

Do You Really Need a Standby Pump?

Depending on the critical nature of the plumbing system you may not even need a standby pump. Let’s look at the load profile shown above. Over 95% of the time, the load is less than 70% of the design GPM. We may even think these numbers are oversized since we based the flow rate on a modified hunters curve. Look at the 33% pump choice.

If there are only three pumps at 33% each and no standby, what happens if we lose a pump? The end of curve in this example is 108 GPM. If only two pumps are available this adds up to 216 GPM capacity. 70% of the design flow rate is 210 GPM. This means, in an emergency, two pumps can handle the load 95% of the time.

If 33% of your design flow rate ends up with a selection further left on the curve, there will be a greater percentage of total flow.

Obviously, some systems always require standby: hospitals, process systems, stadiums. When first cost is critical and the building is not critical, I would suggest the 33%-33%-33% pumping system with no standby. An R. L. Deppmann sales engineer can select and offer different pumps with more run out in parallel operation.

Next week, the R. L. Deppmann Monday Morning Minutes will look at the good, better, and best pressure booster choices to help you decide what benefits to specify for your client.

Catch up on recent Pressure Booster Pumping System posts:

- Point of Use Pressure Boosting

- Plumbing System Design; Pressure Booster Domestic Water Recirculation Resource

- What is a Building Pressure Booster?

- Domestic Water “Pressure Booster Pumping System” – Discharge Pressure

- Domestic Water “Pressure Booster Pumping System” – Suction Pressure

- Domestic Water “Pressure Booster Pumping System” – Control Head & Curves