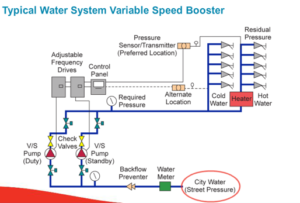

A high rise building will require a pressure booster pumping system. This system includes the pumps and controls for proper operation and smooth pressure control. When sizing the system, it is normal to start by determining the flow rate just as you would in any plumbing design. The next calculation is the pressure required for the plumbing system to properly function. Today, let’s look at that discharge pressure.

A high rise building will require a pressure booster pumping system. This system includes the pumps and controls for proper operation and smooth pressure control. When sizing the system, it is normal to start by determining the flow rate just as you would in any plumbing design. The next calculation is the pressure required for the plumbing system to properly function. Today, let’s look at that discharge pressure.

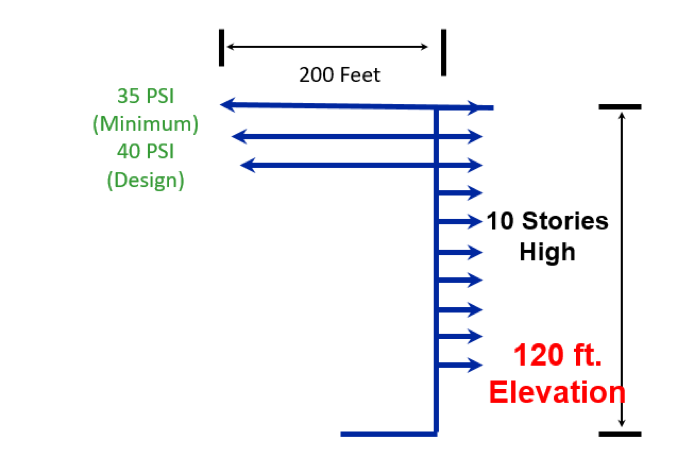

Here is an example system to help illustrate the steps required. We believe we need a pressure booster system so let’s look at the pressure required. Once we have all the numbers we will use the R. L. Deppmann Plumbing Website to do the calculations.

Fixture Pressure

The pressure required at the farthest plumbing fixture is a larger number today than it was 20 years ago. Today it is not unusual to require 30, 35, or even 40 PSIG for a proper flush. If there are multiple fixture brands allowed in your specification, you may want to define a minimum and maximum fixture pressure required so you have enough. Take a look at the products you specify and the pressure required. I tend to default to 35 PSIG minimum and 40 PSIG maximum required as a rule of thumb. The booster systems are variable speed so a few extra pounds will not cause too much of an energy loss.

Elevation and Friction Loss

Obviously, the pumping system has to have enough discharge pressure to lift the water to the top of the system. Along the way to the farthest fixture there will be friction loss in both the vertical and horizontal piping.

Look at the simple sketch above as our example. The elevation is 120 feet and the horizontal distance on each floor to the farthest fixture is 200 feet. Let’s assume for this example that the 120 and 200 feet include fitting losses. You should include any fittings in the total developed length of the pipe. You will also need the friction loss per 100 feet used as the official standard for plumbing systems. We will use 3 PSIG per 100 feet in this example.

Additional Pressure Drop Devices

Once in a while, there is an additional pressure drop item in the discharge piping at the pump. An example of this is a pressure reducing valve or PRV. I am not talking about the zone PRVs we use to reduce the pressure at the lower floors. This would be a PRV in the main at the discharge of the pumping system.

Most codes today require the pressure booster to be variable speed. The ASHRAE 90.1 energy standard specifically says not to use pressure reducing valves unless they are needed as a safety device. If you use bypass electrical starters in your design, you can assume someone will use the bypass and the system will be constant speed when they do. There will need to be some means of controlling the pressure in this situation. I don’t recommend using bypass starters, but once in a while they are used so you would have to account for the pressure drop added by PRV.

Using the R. L. Deppmann Pressure Booster Tool

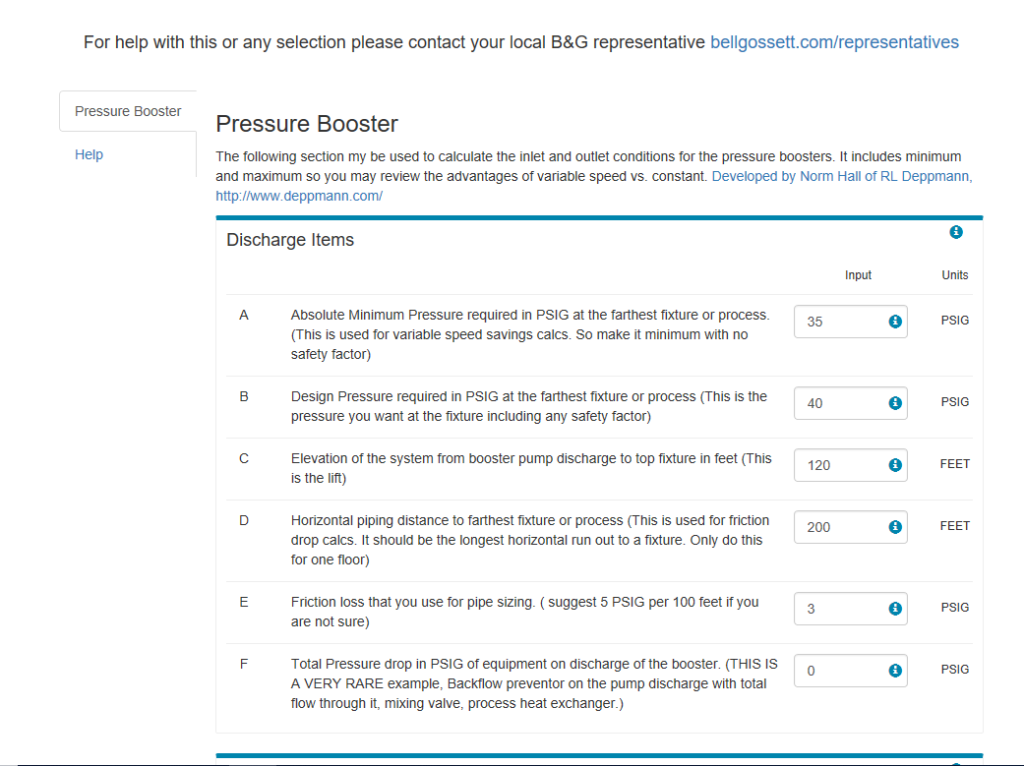

If you go to our website plumbing page at the link above, you can enter your project information in the “engineering selection tool” we offer. The screenshot below shows all of the example information included. There is also a short video showing how to use the tool.

Last week, we defined a pressure booster and how it is different than a simple pump.

Next week the R. L. Deppmann Monday Morning Minute will look at the suction side of the pressure booster pumping system.