Engineers and contractors will turn to a pressure booster pumping system when they determine a building will be short on pressure in the plumbing system. What is a pressure booster and how is it different than a simple pump?

Engineers and contractors will turn to a pressure booster pumping system when they determine a building will be short on pressure in the plumbing system. What is a pressure booster and how is it different than a simple pump?

Decades ago, high rise buildings were served by a storage tank in the penthouse or attic. A simple pump in the basement would turn on when the tank level was at a low point and turn off when the tank was full. The tank held enough water to serve the plumbing load, and often times would also handle a volume of water for the fire hoses. The tank might be open to atmosphere or closed and pressurized with an air compressor.

If the tank was not used for fire protection, why use the tank at all? Why not just have a pump in the basement pressurize the plumbing system by itself? Why not just use a pump? Today the R. L. Deppmann Monday Morning Minutes looks at these questions.

Pressure Booster Gallons per Minute (GPM) Capacity

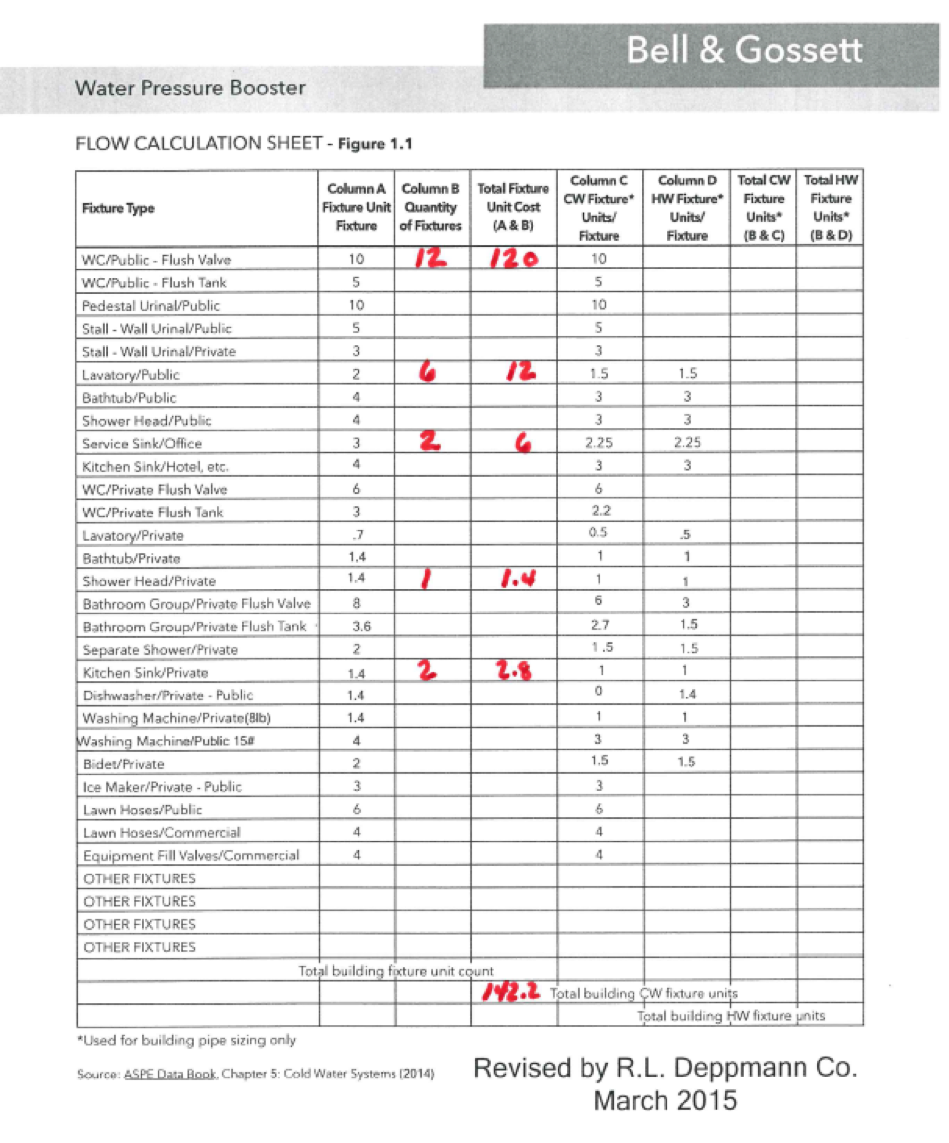

When determining the capacity of a pressure booster pump, we start with the flow rate. Let’s use our Novi, Michigan office as an example. The engineer starts with a fixture unit count and then we turn to the American Society of Plumbing Engineers. Each plumbing fixture has a number of fixture units assigned to it. A water closet (toilet) in a public restroom has a fixture count of 5 if it has a tank type flush and a count of 10 if it has a flush valve. Here is the Flow Calculation example of our Novi office.

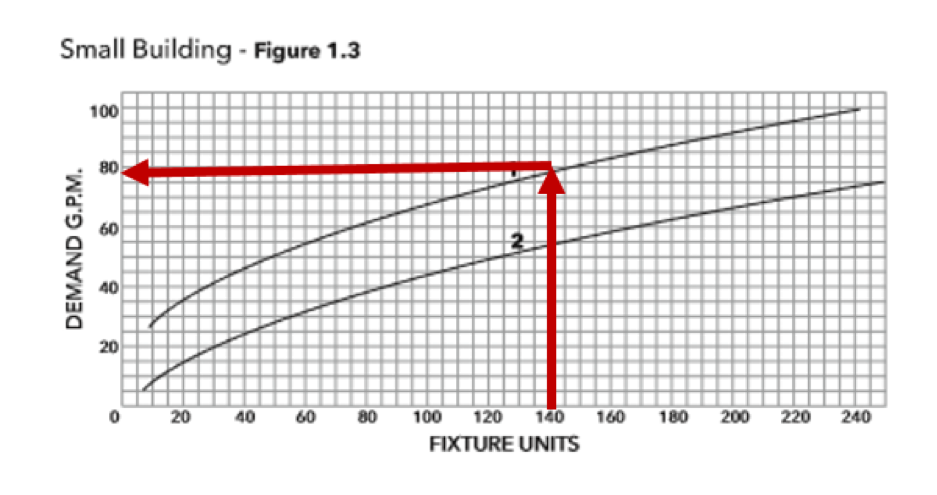

You will notice the total fixture count is 142.2 in this example. Next, we apply a diversity factor to the fixture count. Everything will not be running at the same time. Let’s look at the curve in the Bell and Gossett TEH-1096B manual.

We can see we need about 80 GPM which does not include the lawn sprinkler system since it is coming off the main before the pressure booster. We also did not include the cooling tower makeup here since we do not have one in this facility.

80 GPM feels about right. The flush valves take about 30-35 GPM each for a couple of seconds. There is a possibility that two are flushed simultaneously so the number seems close enough.

Let’s assume for this example that at the design flow rate of 80 GPM, we need an additional 20 PSIG of boost. 20 PSIG is about 46 feet of head so we need to pump 80 GPM at 20 PSIG. Why not just select a pump for that and let it run?

Why Not Just Install a Pump as a Pressure Booster?

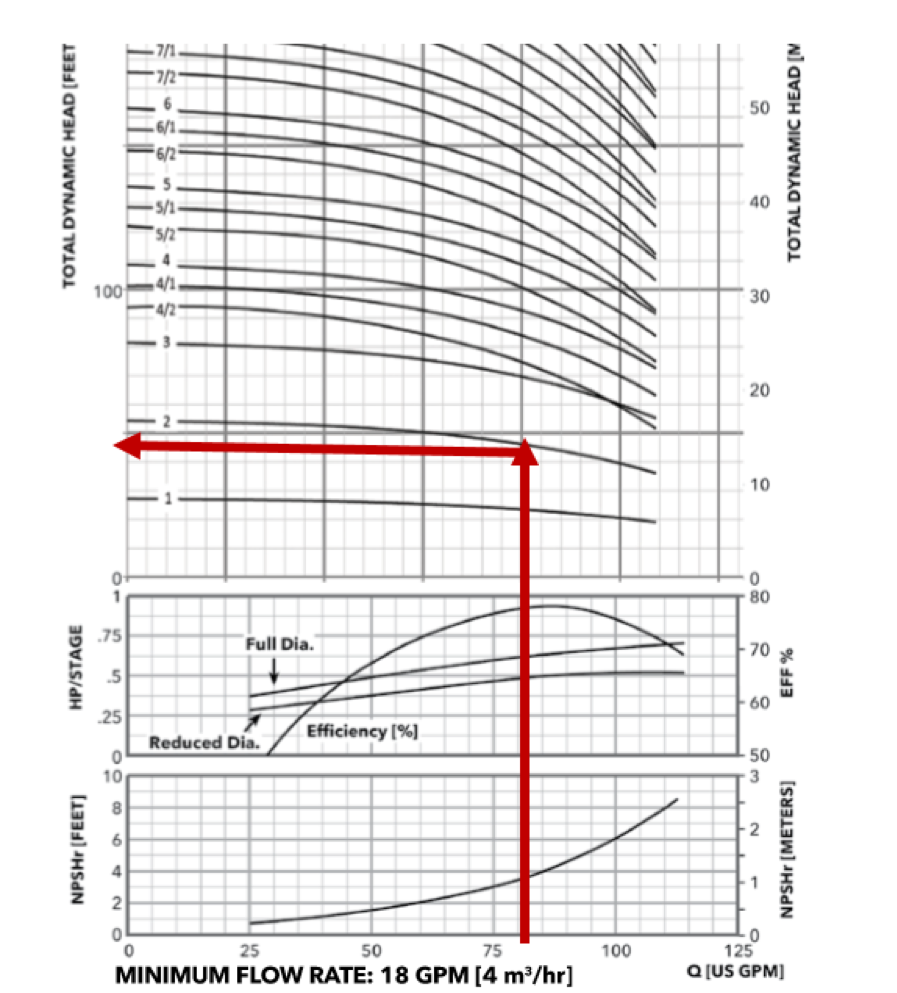

The pump in our example is shown below. We selected a 33SV pump at 1750 RPM. It will do 80 GPM at 46 feet with 2 stages which will require a 1-1/2 HP motor.

At this point, I think of my granddaughter and her book titled, If you give a mouse a cookie by Laura Numeroff. Every time you think of one thing, another thing pops up. Let’s start the list:

- Will you let the pump run all the time? It will waste energy. So we have to turn it on and off. If you put a pressure switch on the discharge, the pump will make the switch when it is turned on. So, we need some other control.

- If you turn the pump off, the pressure will drop and the pump will start again. You need check valves, some storage, and controls to keep the pump from cycling too much.

- If you start and stop the pump too much, the motor may overheat so you need controls to keep it within the motor manufacturer’s recommendation.

- If you turn the pump on at full speed you may get more pressure than you need when the city water pressure increases. So, you need controls to only turn it on when needed.

- The city water pressure and friction loss in the building varies so you may exceed the maximum pressure and also waste money running at full speed. You may want to add a variable speed drive. Besides, it may be required to meet code in your area.

- As the flow rate drops due to the demand, the pump head will rise. You may want a pressure sensor control to maintain the pressure.

- As the flow rate drops you will approach “0” GPM and at times be at “0” GPM. You will damage the pump so you need controls to protect the pump.

- When the demand changes quickly you may want to avoid large pressure changes. They may be too high or too low. I know… we could use controls.

- If the pump fails you may want to alert the manager that the pump needs repair. Maybe you need some controls?

- If the pump fails there may be a shortage of water or pressure so you may want a standby pump. If you have a standby pump you may want to automatically turn it on. How about some controls?

- If the flow rate is low most of the time you may want to stage a couple of smaller pumps so you are not running a large horsepower all the time. Staging will require controls.

- If a pump fails you may want to service it without shutting down the whole building water supply. Controls?

- What did I miss? Controls?

Why not simply use a pump? A pump will need controls and the controls make it a pressure booster system. R. L. Deppmann has a variety of pressure booster systems available. Visit our plumbing website for more information (Internet Explorer browser is not supported).

Next week, we will look at the pressure calculations using the R. L. Deppmann Plumbing website.