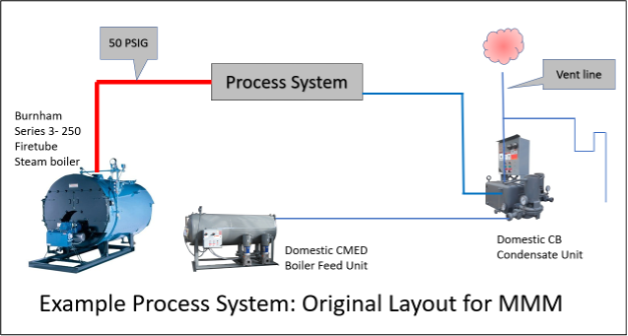

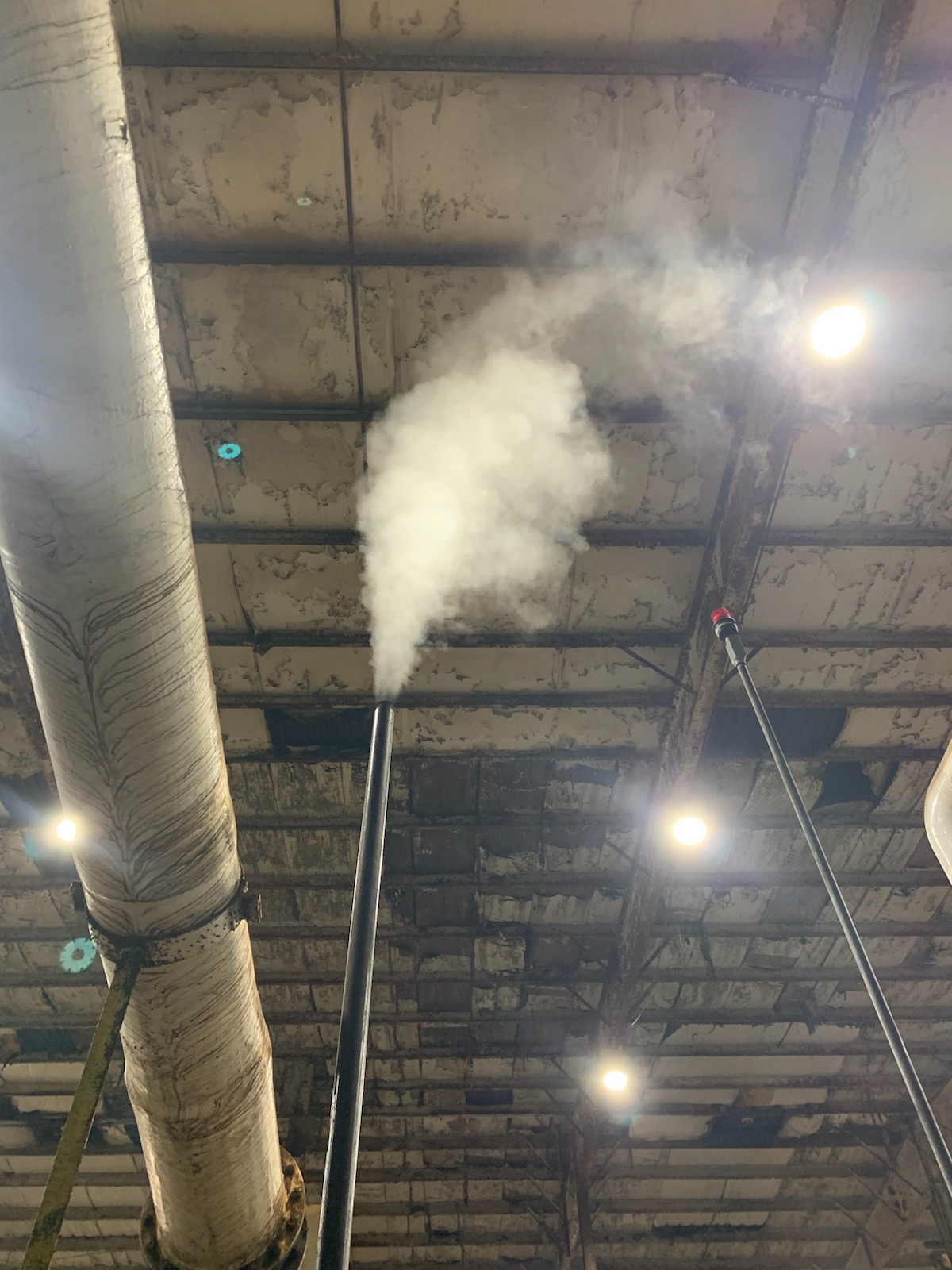

We received a call from one of our wholesalers with an industrial customer experiencing a flash tank issue. The industrial customer was using 50 PSIG steam in their process. The condensate was flowing back to a condensate unit and a large volume of steam was exiting the condensate unit vent.

We received a call from one of our wholesalers with an industrial customer experiencing a flash tank issue. The industrial customer was using 50 PSIG steam in their process. The condensate was flowing back to a condensate unit and a large volume of steam was exiting the condensate unit vent.

The customer solved one problem and replaced it with another.

The Condensate Handling Issue and Solution

The original issue was the steam exiting a vented condensate receiver. The owner was concerned about the short life of condensate pumps. In addition, there was steam shooting out the condensate unit vent line. There was a concern about the energy being wasted. An engineer was called out to look at the problem.

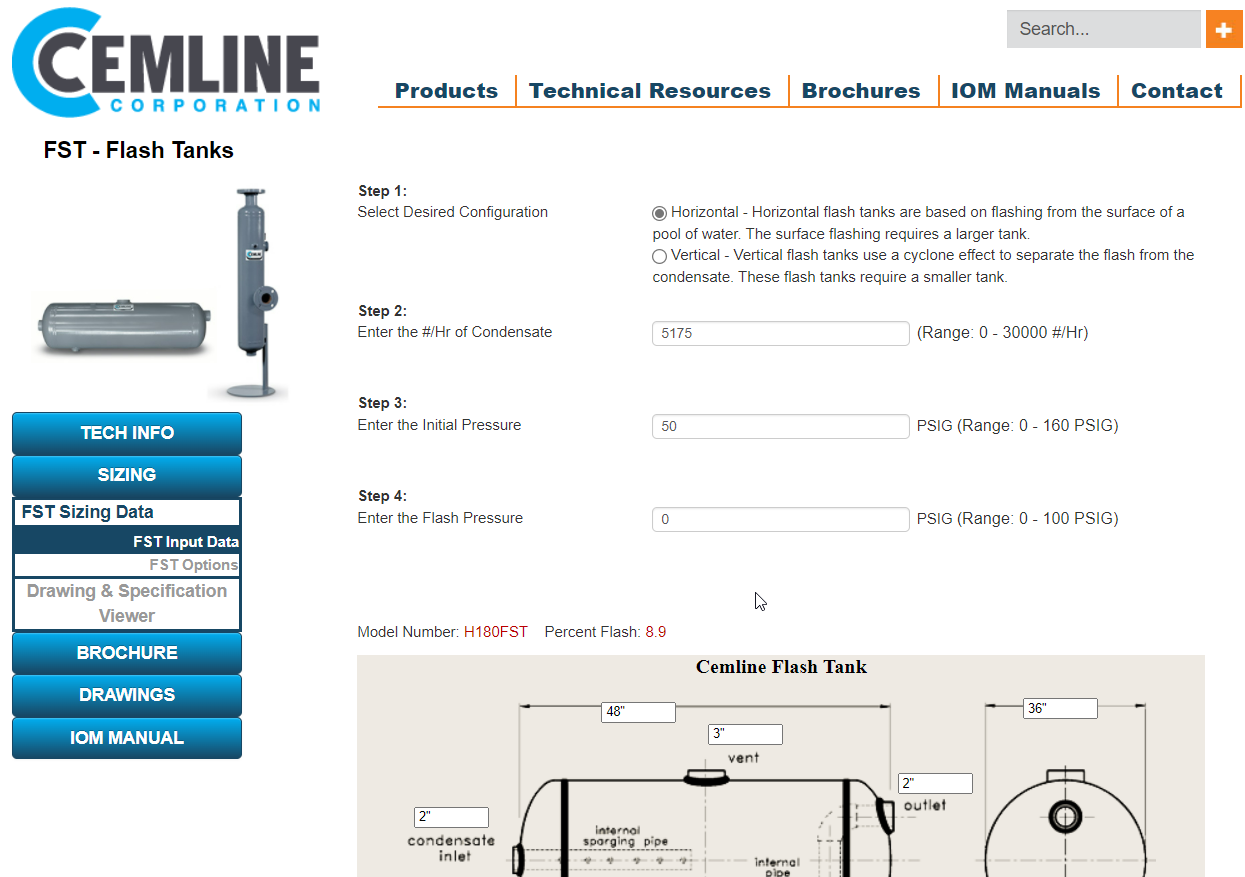

The issue is the temperature of the condensate. The 50 PSIG steam has a saturation temperature of 300⁰F. The condensate unit is a short distance from the process. The steam is flashing in the vented condensate unit. This will cause a short pump life. The engineer sized a flash tank to avoid the condensate unit problems.

The flash tank was sized to drop the condensate temperature from 300⁰F to just below 212⁰F. For this example, we assume the boiler and load was 150 HP. The pounds per hour of steam available is approximately 150 HP X 34.5 PPH / HP = 5175 PPH. If the engineer wanted a horizontal flash tank the Cemline flash tank solution would be:

Notice the “percent flash” shown is 8.9%. That means that as much as 460 PPH (5175 x 0.089 = 460.58) of flash steam at 0 PSIG could be lost up the vent of the flash tank. This is what the owner experienced once the flash tank was installed. The condensate unit was now protected but there was still flash steam now coming out of the flash tank.

Using the Flash Steam to Recover the Energy.

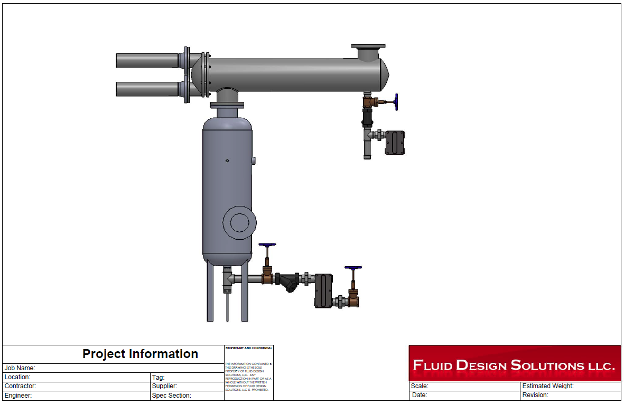

We were called out to provide options for the flash steam. The owner could not use the 0 PSIG steam directly anywhere close to the condensate unit and flash tank. Piping the steam to an area for use was cost prohibitive.

Our sales engineer remembered a previous R. L. Deppmann Monday Morning Minutes series on flash tanks, “Medium and High-Pressure Steam Vented Flash Tank Trim”. We could use a Bell & Gossett QSU steam to water heater exchanger with modified openings and stainless-steel tubes. The water side of the heat exchanger could be domestic water, the boiler makeup water, or process water. During times where a low or zero load may exist, this design will still provide venting same as using the flash tank only.

There are several potential uses for the 460,000 BTUH of lost flash steam. The simple solution shown above will save energy and operating cost for the owner.