Vibration control is critical in all buildings for the comfort of the occupants. All rotating devices in the HVAC system cause vibration and pumps are no exception. Today the R. L. Deppmann Company Monday Morning Minutes looks at Vibration Control in pump installations and the use of inertia bases sometimes called vibration bases.

What is an Inertia Base?

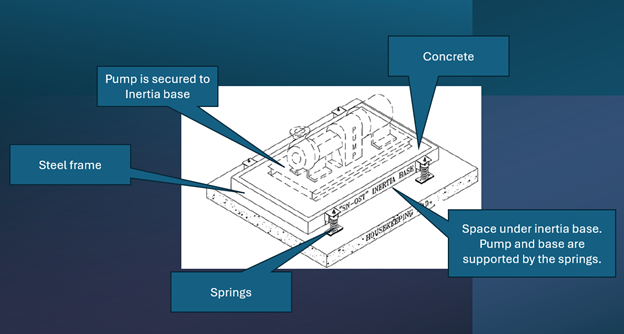

An inertia base is a steel frame which will be filled with concrete on the jobsite to add a solid, heavy platform for the pump mounting. The base has springs mounted on the sides and/or front and back. The springs are set so the base with concrete is “floating” above the housekeeping pad. The concrete and steel base becomes very heavy to retard the vibration along with the springs.

The American Society of Heating, Refrigeration, and Air conditioning Engineers (ASHRAE) publishes a HVAC Applications handbook. Chapter 49 is about noise and vibration control. This chapter referred to inertia bases as concrete bases (Type C).

When Do You Use an Inertia Base on Pumps?

Ground Floor Installation — No Inertia Bases Required

The amount of vibration your client, the building occupant, can accept is obviously subject to what is happening in the building. An operating room or laser facility will have tighter vibration criteria than a school or office building. ASHRAE Chapter 49 section 3.3 addresses the special situations. The engineer should work with the vibration Isolation representative for special situations.

When do you need a pump inertia base? The goal of the base is to add weight to the pump and dampen any vibration. Over decades, R.L. Deppmann has learned and taught that there is no greater weight to add to a pump than mother earth. We have suggested that a Bell & Gossett (B&G) base mounted pump be installed per the manufacturer’s instructions. B&G’s installation instructions P2001406 suggests:

“The best pump location for noise and vibration absorption is on a concrete floor with subsoil underneath. …. The foundation must weigh at least 2-1/2 times the weight of the pump unit. …. Tie the concrete pad in with the finished floor.” B&G suggests the vibration isolation base when the pump is mounted on upper floors.”

R.L. Deppmann, from the time of Ray Deppmann, Zaven Margossian, and Bob Whymer, has always said, “If the B&G pump is located on the lowest floor, a vibration base is not necessary. Use a vibration base when the pups are located on upper floors.”

The pump should be properly aligned, shimmed, leveled, and grouted to the concrete pad. Whether the pad is a housekeeping pad or an inertia base, the pump installation remains the same.

What happens if you do not have a B&G pump with its quality of manufacturing? The ASHRAE Applications handbook has table 47. In this table they recommend using the concrete base for all end suction and double suction split case pumps regardless of location in the building. Even slab on grade installations. Each engineer should decide for their client. R. L. Deppmann is the manufacturer’s representative for both B&G and Vibration Eliminator Company. We will gladly accept an order if specified.

How is the Base Selected for a Base Mounted Pump?

The base is selected based on the size and weight of the pump and the required deflection. The engineer should identify the amount of deflection required and let the base manufacturer determine size and depth of the inertia base.

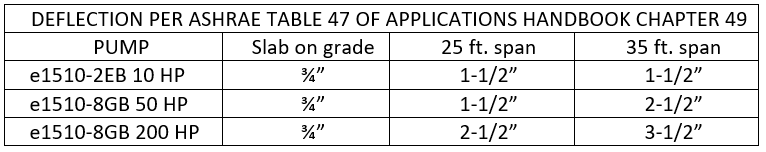

Deflection: The deflection is based on the size and weight of the pump and the floor span. ASHRAE’s table 47 previously mentioned has criteria for the deflection. Here is a sample taken from that table. We will use two B&G e1510 base mounted end suction pumps.

The springs provided will determine the deflection. You can see the minimum deflection will always be ¾.” The space under the inertia base will also help when cleaning the floors.

Length and Width: The size will be based on the pump dimensions. The pipe elbows attached to the pump will be included on the vibration base. There will be allowance all around the pump of additional base. Vibration Eliminator Company uses 4” all around the pump base. This ensures the pump is mounted on level concrete and not near the lip of the steel base and avoids rough concrete edges. It also makes sure the pump mounting bolts are not too close to the edge of the concrete base.

Depth: The depth is no less than 1/10th of the length between the springs. It may be more if needed to achieve the weight required for the deflection needed.

Proper Installation Tips:

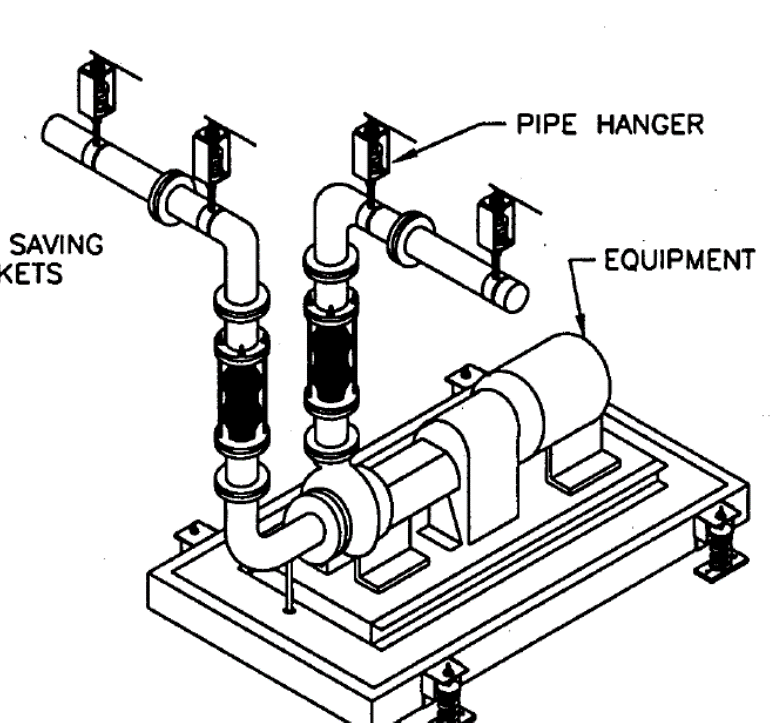

Make sure your specifications and detailing are clear and follow the manufacturer’s installation instructions. The sketch above does not follow anyone’s installation instructions.

We did want to point out a couple of things. The pump on an inertia base must have spring hangers on the overhead pipe. There should be a minimum of five spring hangers on both the suction pipe and the discharge pipe headers. The inertia base is sized for the weight of the pump and motor and a 10 ft. column of water. If the rise is greater than 10 feet, you must let Vibration Eliminator know. The vertical weight of the pipe as well as the headers are supported by the spring hangers and are not included in the base calculations.

Flexible connectors should be selected for the movement expected. They also assume that the weight of the pipe is supported by the spring hangers and not by the base.

Properly installed vibration bases or inertia pads or concrete pads will help make your client satisfied with your design. Please contact your sales engineer if you have questions or would like a short class for your engineering staff.