During a recent visit to a K-12 school hydronic system, I was asked if there was a way to determine the total system volume. My tongue and cheek response was to advise them to take out the tape measure and start measuring. Once the shocked looks dissipated, I suggested another simpler way to estimate the system volume in an existing hydronic heating system.

During a recent visit to a K-12 school hydronic system, I was asked if there was a way to determine the total system volume. My tongue and cheek response was to advise them to take out the tape measure and start measuring. Once the shocked looks dissipated, I suggested another simpler way to estimate the system volume in an existing hydronic heating system.

Why Would You Need to Calculate the Volume of an Existing System?

Besides being a possible question in a master’s program exam in a HVAC program, why bother calculating an existing system volume? There may be many reasons, but I often get asked for three reasons.

The first is an addition or change to existing hydronic system through expansion. If I add 300 gallons to the system, do I need to change the expansion tank, add a new one, or just use the existing tank?

The second reason is the addition of glycol to the system. Assume for a moment that the engineer was called to solve freeze-up issues. She finds the issue is old equipment and maintenance issues, but the owner does not have the capital for a major expansion. The windows have changed and the building if tighter and the engineer is sure the boilers can handle the capacity reduction due to the addition of glycol. Now the question is how much glycol do we need? The answer depends on the system volume.

The third reason, and the reason I was called, has everything to do with cold fill pressure. There was a small addition to the system. A coil was added two floors up in the system. When this simple coil and piping was added, the volume only increased by 80 gallons. Not much of a change. The fill pressure would increase from 28 PSIG to 37 PSIG. The first-floor boilers had 75 PSIG relief valves. The system was small and had a Bell & Gossett D-280 expansion tank. How would this change?

Existing Expansion Tank is Used to Calculate the Volume

The closed hydronic heating system expansion tank has one main purpose. The purpose of the expansion tank is to maintain a reasonable pressure in the system as the water is heated from the fill temperature (40°F to 60°F) to the heating system design average temperature. A perfectly sized expansion tank will start at the minimum pressure at room temperature in the system. As the system is heated, the pressure will rise. When we get to the maximum temperature in the system, the pressure will remain just under the maximum pressure at the boilers based on the relief valve sizing.

We can use the physics of this to determine the approximate system volume.

Example Expansion Tank Sizing

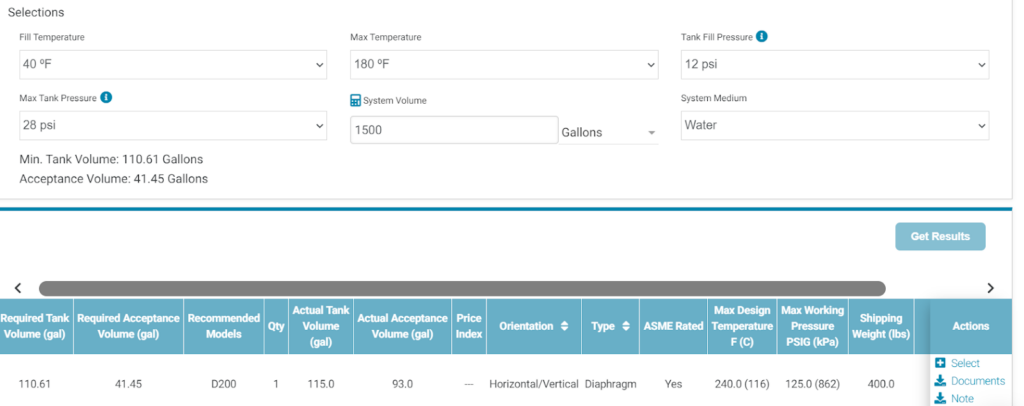

An example will help make the idea clear. A recent schedule showed a Bell and Gossett model D200V expansion tank. The schedule showed the system volume at 1500 gallons of water with an initial temperature of 40 and a maximum temperature of 180. The fill pressure at the tank was shown as 12 PSIG with a maximum pressure of 28 PSIG. The Bell & Gossett esp-Systemwize program results follow.

The system was single story with 3” mains and 1500 gallons appeared to contain a significant safety factor. This is not surprising. In over 40 years of engineering and sales in this industry, I have come across 9 systems with undersized expansion tanks. We use a good amount of safety factors.

We need to make sure that the expansion tank is at the right starting or fill pressure. If we cool the system down so the average temperature is very low, we can see where the pressure goes to at a higher average temperature and “reverse engineer” the sizing to find the volume.

In our example, the fill pressure at the tank was verified to be correct at 12 PSIG and the tank was charged properly to 12 PSIG. The starting pressure is 12 PSIG.

We started by bringing the controls into the full heat position. Now shut down the boilers while the pumps are operating. Watch the temperature in the system drop. In our example, the supply drops to 110° and the return temperature comes back at 90°. The average system temperature is (110° to 90° brings the average to 100°).

Now we keep the controls in the full heat position and fire a boiler. Allow the system to heat up and check the thermometers. When we get to 170°, for example, the return temperature is 140° for an average temperature of 155°.

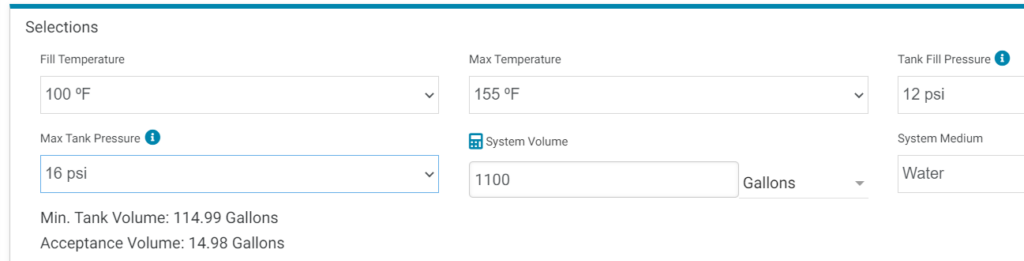

At this point the pressure at the expansion tank is up to 16 PSIG. What is the volume? Go to the esp-Systemwize program and enter the known values.

- Fill pressure 12 PSIG.

- Maximum pressure 16 PSIG.

- System starting temperature 100°F.

- System final temperature 155°F.

- Tank is a Bell & Gossett D200 with a tank volume of 115 gallons and an acceptance volume of 93 gallons.

Adjust the system volume and keep entering until the tank size gets close to the existing tank volumes. After many iterations, I found the following:

The system volume is about 1100 gallons. The engineer can apply some safety factors and use this volume. Please note, it is important to get the pressures and temperatures as accurate as possible. Replacing small gauges with a large range with a larger gauge with a small range such as 0-30 PSIG would help. In fact, since the maximum pressure was 28 PSIG to begin with, a 0-30 PSIG or 0-60 PSIG gauge would have been a great choice during construction.

A few notes:

- Make sure the fill pressure is correct for the system Visit Cold Fill Pressure – Expansion and Compression Tanks – Part 4.

- Adjust the pressure readings based on where the gauge is located. Visit Expansion Tank Air Side Maintenance Schedule for more information.

- Many engineers size expansion tanks at the design temperature of the supply rather than the average temperature of the system. This gives an additional safety factor. Visit Expansion and Compression Tanks Formulas – Part 2 for more about this topic.

- If you want to verify the maximum pressure scheduled is correct or if there is additional room in that number, visit Maximum Pressure of Expansion and Compression Tanks – Part 5 and Max Pressure of Expansion and Compression Tanks (Cont) – Part 6.

Need Some Help With This?

An interesting point just occurred to me. I often get comments and questions from around the country and even in different countries than the United States and Canada. The Bell & Gossett representatives across the country are regularly discussing these blogs.

The Bell & Gossett exclusive representatives in each state or territory are well-trained engineering teams in hydronics, steam, and plumbing. They understand this stuff inside and out. That is different than most distributors and wholesalers who may understand the products and selections but have less engineering and troubleshooting experience.

If you need help, reach out to those representatives. If you are not sure who to call, visit Our Manufacturer’s Reps | Xylem US for assistance I know you will treasure.