We often get questions about using Bell & Gossett pumps in institutional and commercial chlorinated water swimming pool applications. Here are a few suggestions about the pool circulating pump materials of construction and selection.

We often get questions about using Bell & Gossett pumps in institutional and commercial chlorinated water swimming pool applications. Here are a few suggestions about the pool circulating pump materials of construction and selection.

Types of Centrifugal Pumps Used in Public Pool Applications

The American Society of Plumbing Engineers (ASPE) Plumbing Design Manual Volume 3 has a Chapter 6 called Public Swimming Pools. Here, ASPE suggests horizontal end suction, vertical turbine, or vertical inline style pumps are options. The Bell & Gossett e1510, e1531, e1532, and e80 are examples of these styles of pumps. These styles of pumps are not self-priming. These pumps should be used in applications with a flooded suction. I remember our former RLD startup and warranty manager, Dale Zuehlk’s famous line, “our pumps don’t suck.” A bit of history: Years ago, we used cast iron pumps with cast iron impellers for institutional pool applications. These materials of construction gave a reasonable trouble-free life in properly water balanced applications where the pump ran 24 hours a day without starting and stopping or cycling. For pools that cycled the pump, the cast iron would cause a shot of rusty colored water on startup. Not a pleasant sight for owners. In those cases, stainless steel was often used to eliminate the shot of rust.

Bell & Gossett Pumps – Materials of Construction

The Bell & Gossett “e” series of centrifugal pumps have stainless steel impellers. This material is used to meet the plumbing requirement of low lead content. It is also used to increase the efficiency of the pumps. Most of the pump bodies or volutes are cast iron. When asked about swimming pool applications, B&G and Deppmann have the following recommendations. Use the “e” series Bell & Gossett pumps mentioned above. Use the published specification for the B&G pump you choose and make the following adaptations when using chlorinated water.

- Body or Volute: The volute shall be cast iron with the internals epoxy coated. The pump shall be supplied with volute wear rings. The epoxy coating gives a layer of protection from rusty water if the pump is down for service, or if you have a standby pump.

- Impeller: The impeller shall be cast 304 stainless steel. The SS gives better life expectancy than the traditional bronze impellers.

- Seal: the pump seal shall be mechanical. The seals shall have EPR elastomers, stainless steel spring, and silicon carbide face rotating against a stationary silicon carbide face (SiC-SiC). This silicon carbide to silicon carbide mating provides better protection against solids particulate in the water. It also stands up to the higher ph.levels of 7.8 to 8.2 sometimes caused by over chlorination.

Swimming Pool Pump Selection and Clean/Dirty Filters

It is hard for me to write an article about pumps without including something about the selection and operation on the pump curve. Public swimming pool pumps normally pump into the filtering system. The two conditions to be aware of are the pump head with a clean filter and the pump head with a dirty filter. The pump flow rate is normally the GPM required to turn the pool volume over in the number of hours required by code. This flow rate must be achieved whether the filter is clean or dirty. The engineer should select ensuring the operation between these two extremes will not cause damage to the pump.

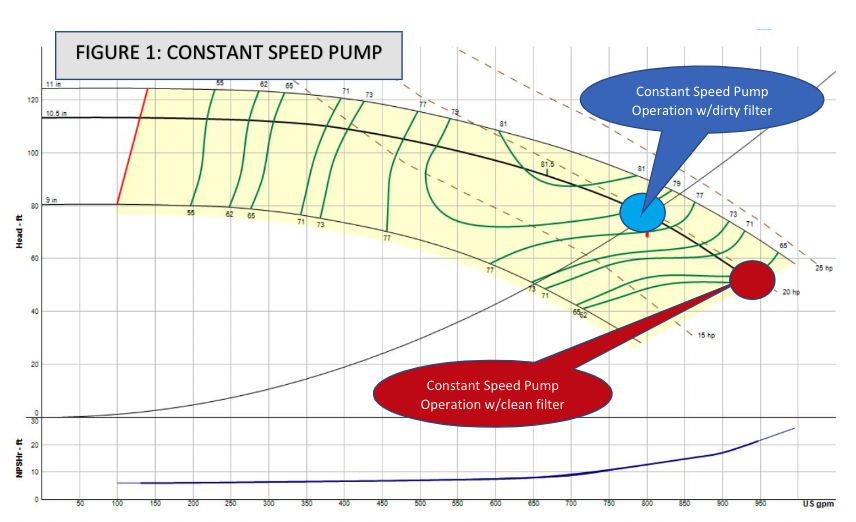

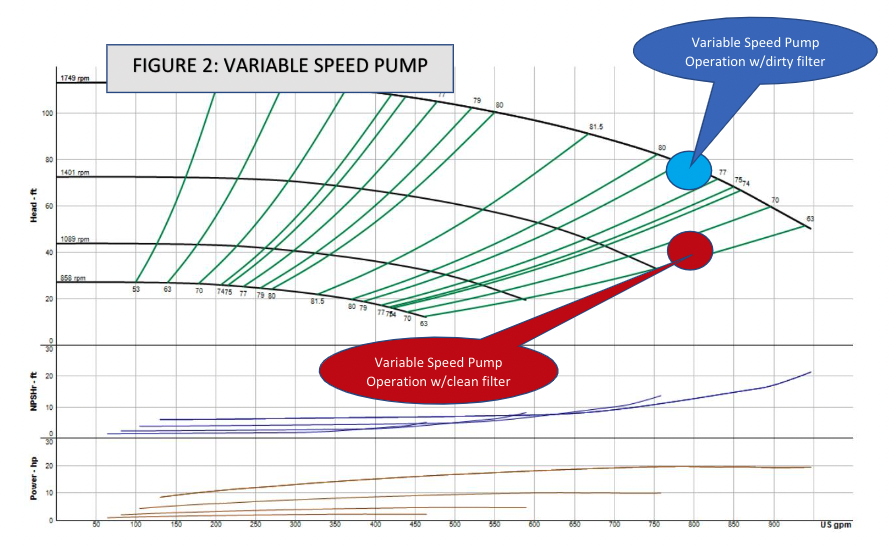

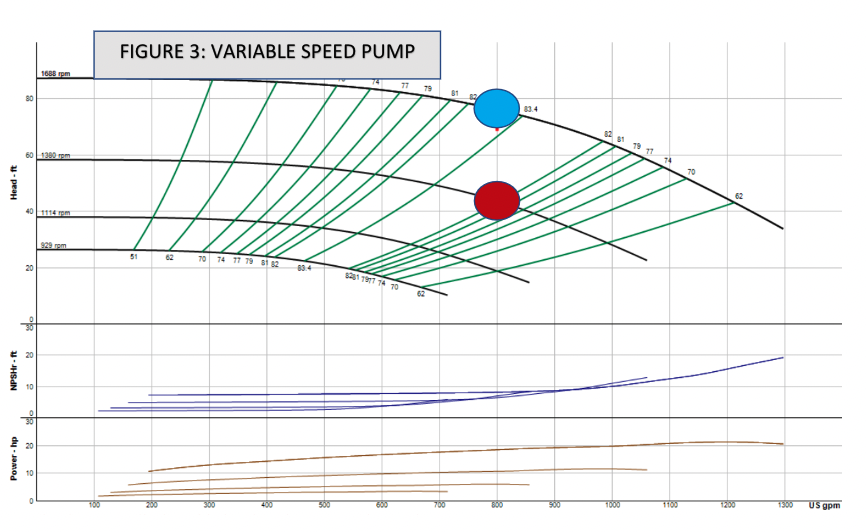

Here is an example. Assume the flow rate is 800 GPM. The filter has a pressure drop of 5 PSIG (12 feet) clean and 20 (46 feet) PSIG dirty. The balance of the friction losses adds up to 15feet in this example. The elevation required is 15 feet. The pump capacity is 800 GPM at 76 feet with a dirty filter and 800 GPM at 42 feet with a clean filter. Look at the following two selections.

Figure 1 shows a constant speed pump. The selection at worst case is the blue dot. It meets the standard suggestion of being less than 85% of the end of curve. When you look at the clean selection, the pump runs out on the curve. The operation is at or just past the last acceptable point of operation. This is a case where selecting a pump farther back on the curve would be a prudent choice.

Figure 2 shows the variable speed curve. Either state code or prudent use of energy would suggest a variable speed pump is the way to go. The selection at worst case is the blue dot. It meets the standard suggestion of being less than 85% of the end of curve. When you look at the clean selection, the pump remains at 800 GPM and the speed drops to 1530 RPM. The operation is at or just past the last acceptable point of operation. This is a case where, again, selecting a pump farther back on the curve would be a prudent choice.

Figure 3 is an excellent selection whether it is constant speed or variable speed. It will cost 10% more but those few hundred dollars are well worth the investment. We could use a Badger Magnetic or Ultrasonic flow meter output as the set point of the variable speed drive. Once set at 800 GPM, we take care of filter issues, strainer issues, and safety factor issues all at once.

This R. L. Deppmann Monday Morning Minutes offered you the quick and easy pump specification and selection changes needed to provide the owner of the commercial or institutional swimming pool with a quality Bell & Gossett recirculation pump.