Featuring the Bobco Gauge Package – The Most Accurate Gauge Reading Possible

This video discusses:

- The benefits of using a single gauge kit for pump readouts

- How to properly pipe your gauge kit

- The Bobco Single Gauge solution

- How to take differential pressure, static pressure, and deadhead/shutoff readings

- Understanding the difference between standard gauges and the Hydronic Indicator

Video features a Bell & Gossett e1510 base mounted end suction pump.

Note: Formula for calculating Feet of Head is different if your system contains glycol. For more information on how to calculate for a glycol system, click here to read our in-depth Monday Morning Minute.

Mounting two similar standard pressure gauges on a pump, one on the pump inlet and one on the outlet, is a common method of determining pump operating condition. Unfortunately, this presents two significant problems for the person servicing the pump:

- Accuracy errors in this method are compounded. Instead of having the rated accuracy of the one pressure gauge, of say 2 percent, the error would be doubled to 4 percent.

- Possibly the bigger issue, many operators have not been trained as to why there are two pressure gauges on the pump. History shows that many operators, when asked why there are two pressure gauges, simply cannot answer the question. Very often the operators have no idea that they are supposed to subtract one pressure gauge reading from the other. Even if they do, they may not truly understand the importance of that calculation and how to convert that pressure in pounds per square inch to feet of head.

Bobco Gauge Package

The Solution: No Error, No Mistakes, and Easy to Understand

The Bobco Gauge Package

Single Gauge Kit Properly Piped on Pump

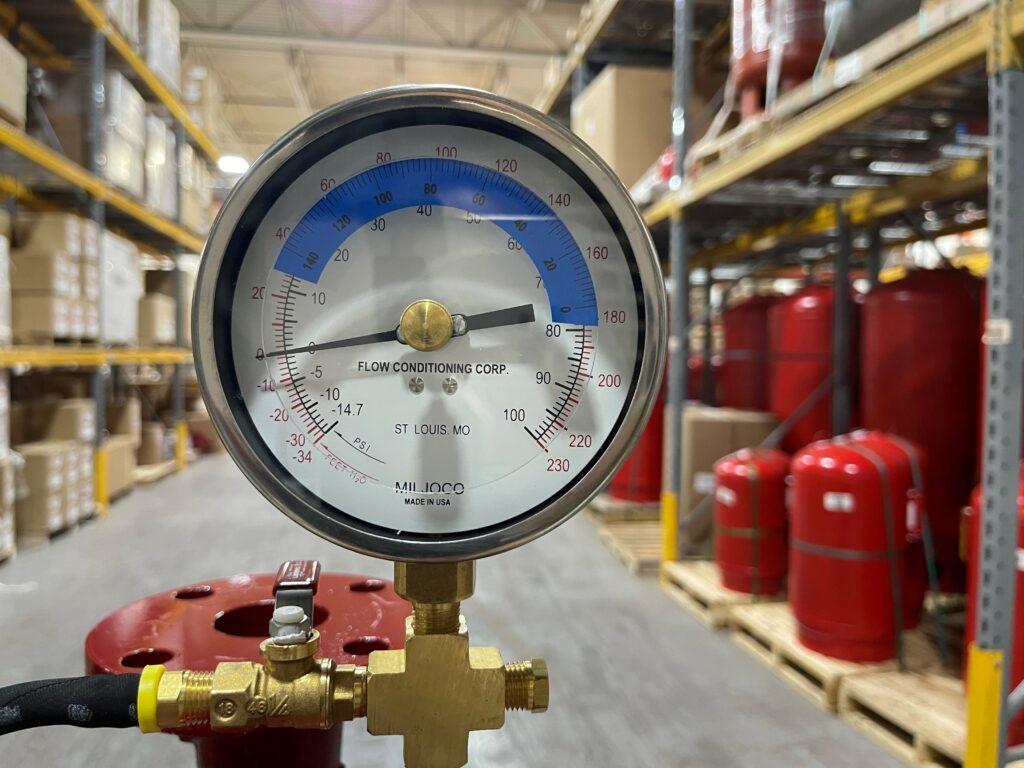

The standard Bobco Gauge Package is designed to give the most accurate gauge reading possible on a centrifugal pump. Differential pressure gauges can greatly reduce system operating errors, improve system efficiency, protect expensive equipment, and reduce maintenance time. The standard Bobco kit will come with a Miljoco 4.5” stainless steel contractor gauge with a 30, 60, or 100 PSI gauge.

When used with the optional Flow Conditioning Corporation’s Hydronic Indicator Gauge, readings are given directly in feet of head, eliminating the need to convert from PSI.

Optional Flow Conditioning Corporation Hydronic Indicator Gauge

The Bobco Gauge Package shutoff valves and fittings are all brass construction. The hose is constructed of synthetic rubber tube which is a textile braid enforced with a synthetic rubber cover.

One differential pressure gauge, installed using the same taps at the pump inlet and outlet, can eliminate the problems noted above. Note that the gauge kit will need to be installed properly on the pump suction and the pump discharge ports to ensure the readings are usable. By eliminating the use of two gauges, the rate of error will drop to the accuracy rating for the single pressure gauge.

Monitoring differential pressure reduces confusion, errors, and inaccuracies and presents conditions on a single, easy-to-read dial. In addition, switches or transmitters can be added to allow for local and remote monitoring in one unit.

Deppmann does offer these packages for most all of the Bell & Gossett pumps we sell, including inline, base mounted end suction and double suction pumps. Hydronic equipment is an important cog to any building’s proper use and function – protect it with a low-cost Bobco Gauge Package for optimal maintenance. Contact us for assistance in designing the best package for your applications.