The ASHRAE young engineers heard about the free cooling system in the recent tour of the DTE Vantage Dearborn Central Energy Plant. The free cooling system has many advantages in these cold northern climates. What basic equipment knowledge does the design engineer need to know? The topic of today’s R. L. Deppmann Monday Morning Minutes is all about free cooling heat exchangers.

The ASHRAE young engineers heard about the free cooling system in the recent tour of the DTE Vantage Dearborn Central Energy Plant. The free cooling system has many advantages in these cold northern climates. What basic equipment knowledge does the design engineer need to know? The topic of today’s R. L. Deppmann Monday Morning Minutes is all about free cooling heat exchangers.

What is Free Cooling?

Free cooling is a bit of a misnomer since it is really not free. The free cooling system uses the cooling tower in the winter months to cool the chilled water return water without turning the chiller on. This water is pumped through a heat exchanger with the closed loop cooling secondary system on the other side. The tower water is allowed to drop down below 45°F to cool the chiller water return. It is free of the mechanical cooling that uses refrigeration. This system requires the cooling tower to operate in the winter. It also requires the cooling tower pump to operate in the winter.

All this said, it makes perfect sense to provide a free cooling heat exchanger system for operation in winter months in the northern climates. It will result in a “cost less” cooling system.

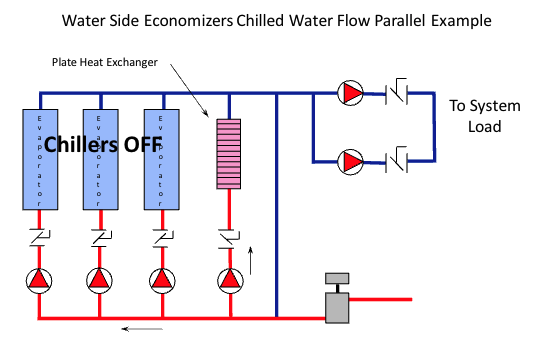

Piping of the Free Cooling Heat Exchanger – One Example

This is one example of the elementary piping of the free cooling heat exchanger. This example shows a parallel installation of the free cooling heat exchanger in a front-loaded position. I will address several piping choices in later articles this year as well as the control. Let’s move on to the heat exchangers.

Free Cooling Heat Exchangers

There are several suggestions for the free cooling heat exchangers that border on “rules.” Here are five suggestions for your design.

1. Type of heat exchanger: The correct heat exchanger to use in free cooling is the gasketed plate heat exchanger. The Bell & Gossett GPX shown above is a typical example. Shell and tube heat exchangers cannot provide the deep temperature cross and close approach needed in this application. The brazed plate models should not be used since they cannot be easily cleaned when fouled or plugged. Visit our past blog, Heat Exchanger Types and Where to Use Them: Part 2 – Plate Style, for more information.

There is a B&G plate option called Free Flow which has larger channels. It would be worth checking into the solution with these plates.

2. Tower side flow rates should remain constant: The gasketed plate heat exchangers have very small passageways. There are numerous channels, and the best heat transfer is achieved with higher velocities. The higher velocities also serve to scour the plates to assist in cleaning. The open cooling tower water is dirty and contains particulate. Reducing the flow rate in the plate will cause the exchanger to plug faster. Visit our past blog, Heat Exchanger Types and Where to Use Them: Part 4 – Variable Flow Applications, for more information.

3. Keep the temperature approach at 3 degrees: Plate exchangers can provide deep temperature approaches. If the tower water arrives at the heat exchanger at 42 degrees, it may be possible to have the chilled water supply at 43 degrees. The temptation to ask for a heat exchanger to do that one-degree approach is huge. The CAPEX or first cost to do that will be prohibitive. I suggest a 3-degree approach will give the best combination of capital first cost and OPEX or operating cost. One example would be tower water from 42°F to 52°F and chilled water from 55°F to 45°F. Visit our previous blog, Heat Exchanger Types and Where to Use Them: Part 3 – Close Temperature Applications, for more information.

The numbers scheduled should be extremely accurate. This is a point where the tenths of a degree should be scheduled and demanded. There can be a 10 or 20 percent difference in cost based on those small differences. The industry’s infamous rounding by using 500 for the specific gravity times the 60 minutes should also be abandoned. Use the correct numbers.

4. Installation and maintenance space is key: The free cooling normally comes from an open cooling tower. Owners and contractors are aware of the concerns surrounding tower cleaning. That B&G GPX heat exchanger with its tiny passageways will require cleaning or plate pack replacement. Make sure there is enough room around the exchanger. The plate packs are heavy and bulky. Do the owner a favor and give more space than the minimum. There are options for drain pans and other trim items available from B&G. Visit our past blogs, Gasketed Plate and Frame Accessories, and Accessorize Your Plate Exchangers (Part 2).

Another thought is to avoid using the free cooling system in early May when the cottonwood seeds are rampant. They will quickly clog the heat exchanger channels.

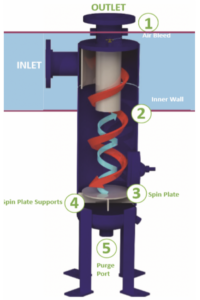

5. Consider a sediment separator: This is a great place to think of using a sediment separator like the General Water Systems CS separators. Check out Sediment Separators in Variable Flow Cooling Tower Water Systems for more information. This is not the place for the multipass separators we use in closed hydronic applications. We need to catch the crude in a single pass.

Look forward to additional free cooling articles this year. There will be more to follow. Contact us if you have an application. We can suggest piping schemes and offer heat exchanger options to help you make a better decision.

PART 2: State Energy Codes

PART 3: Cooling Tower Temperatures

PART 4: Chilled Water Temperatures