The term “overspeeding” in pump selection and operation is a topic of conversation in the world of hydronic design. When asked about this subject I often talk about driving your vehicle. Many people feel comfortable going above the speed limit but want to know that magic number where you are likely to earn a ticket. Overspeeding your pump is acceptable but there are limits. Want to avoid being pulled over?

What is Overspeeding of a Pump?

Most traditional pump curves have a published speed. In a previous R. L. Deppmann Monday Morning Minutes Bell & Gossett ESP-Systemwize: Personalize It!, we showed a video on how to view the constant speed “Oak tree” curves in the Bell & Gossett ESP-Systemwize program. Those curves have a speed with multiple impellers. We know we can reduce the speed and the capacity using a variable speed drive (VFD). Most VFDs will allow you to overspeed a motor if the drive has enough KW capability. Overspeeding is simply operating a motor at an RPM greater than the nameplate RPM of the motor.

Four Reasons to Consider Overspeeding a Pump

There are four key reasons to operate a pump at an RPM greater than the nameplate motor RPM:

- I missed the head calculation and I need a little more at the design flow rate.

- I am selecting a pump near the maximum impeller, but I want “wiggle” room to add pump head if I need it.

- My selection of a larger pump with the lower sized impeller costs more than others. The less expensive pump is close to the capacity I need but I just need a little more.

- I have an existing system which I am adding to and need to add a little more capacity from the existing pumps.

Rules of the Road when Overspeeding a B&G Pump

There are always exceptions to the rules, but just like the introductory comment about breaking the speed limit, it is wise to not stray too far from the published speed. Bell & Gossett (B&G) has a couple of simple rules to follow, listed in ESP Systemwize.

These are the B&G rules as of April 2024:

“When the overspeed option is “on,” Systemwize will consider options for up to 10% higher speed on 4 and 6 pole motors and up to 5% higher speed on 2 pole motors.” – Bell & Gossett

*Note from RLD: 4 pole motors are nominal 1800 RPM. 2 pole motors are 3600 RPM and 6 pole motors are 1200 RPM.

Please consider the following when choosing to overspeed your pump:

- Overspeed is being considered only for max impellers on each pump.

- Motor sizing for overspeed selections considers motor service factor. The drive must be sized to consider motor input power required to achieve duty point BHP.

- Size the motor and drive based on duty point horsepower. This will be the required horsepower in the overspeed condition.

- An inverter-ready motor is recommended, as this has additional winding protection and bearing protection.

- Ensure that your expected loading profile will not require the pump to operate in the overspeed condition for extended periods of time which could impact overall motor life.

If you want to stray from these rules, call your local B&G representative.

Pump Horsepower and Overspeeding

As good as you are, you cannot create energy. A given gallon per minute (GPM) flow rate at a given head will require the right horsepower motor and VFD. If the non-overloading HP at 1000 GPM at 110 feet and 1750 RPM is 40 HP. It will require 40 HP at 1800 RPM, 1850 RPM, or 1550 RPM.

There is more information in a previous article on this same subject: How to Pick an HVAC Centrifugal Pump Part 9: Over Speeding HVAC Pumps & Motors

How Do I Select a B&G Pump for Overspeeding?

Bell & Gossett made it simple for you to view and analyze the overspeeding selections without hiding it from you. Let’s look at an example and a couple of screenshots. Let’s assume you have a client who is interested in both efficiency and longevity in their pumps. You select the B&G e1510 base mounted end suction pump for its long life and want to select a higher efficiency model.

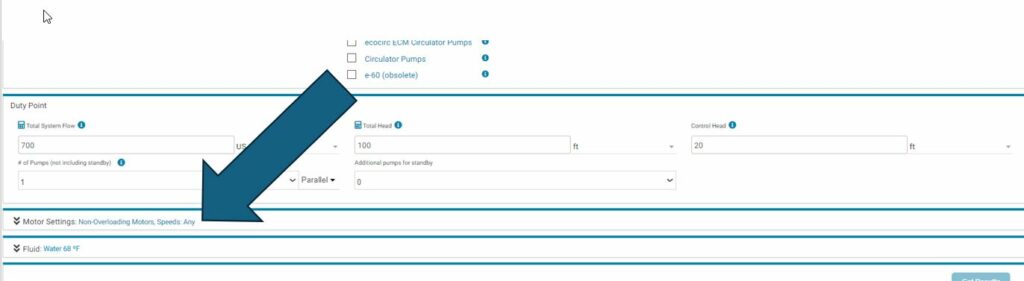

We start with a variable speed selection of 700 GPM at 100 feet. There are potential future additions which would make the future requirement 800 GPM at 110 feet. The client does not want to pay now for larger pumps since the first cost is a consideration. Can you select a low-cost pump with good efficiency that may be adjustable sometime in the future?

Here are a series of screen shots as you select the pump using ESP Systemwize (click on each screenshot for a larger view):

Step 1: We select pumps for 700 GPM at 100 feet. The 3AD selection at 3600 RPM is lower cost. The 4EB selection has a slightly lower PLEV efficiency and is 7% more in cost. Both pumps are 25 HP.

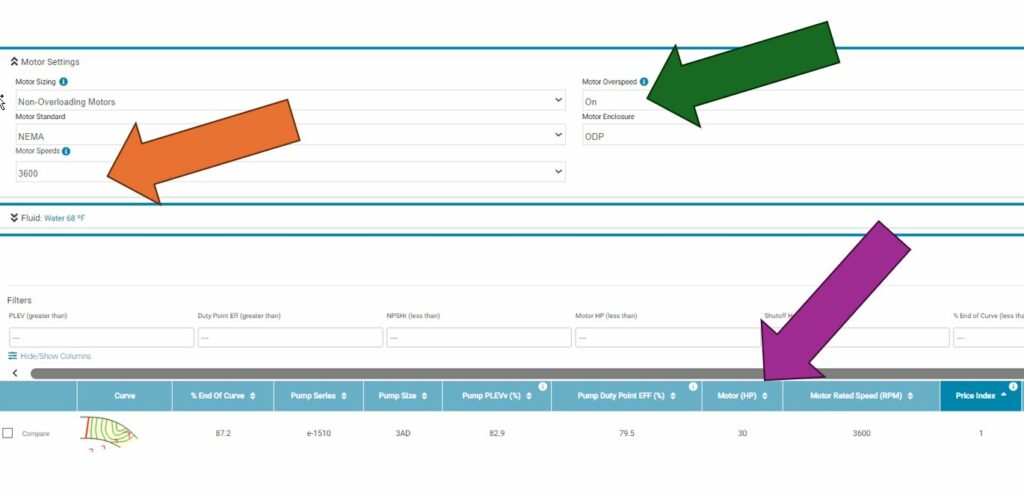

Step 2: Let’s see how these pumps look at the future capacity of 800 GPM at 110 feet. We start by turning overspeeding on. To do this we click on the link under motor settings.

Step 3: This now opens an opportunity to turn overspeed on. We must select a speed so let’s look at 3600 RPM first since that was the lowest cost pump. We turn overspeed on (green arrow). We select 3600 RPM (orange arrow). Once we hit ”Get Pumps”, we see the 3AD pump would require a 30 HP motor. In addition, the point on the curve does not meet the 8% of end of curve suggestion from Basic Centrifugal Pump Selection: Which Pump Do I Choose?

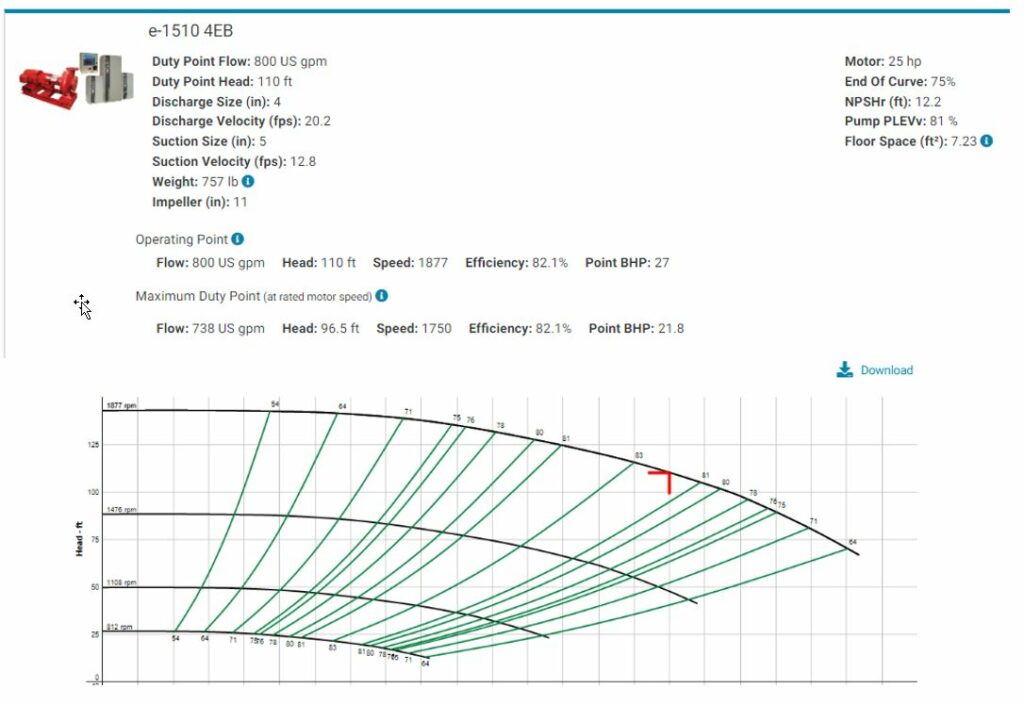

Step 4: Go back and change the speed to 1800 RPM and click “Get Results”. The 4EB pump can do the future job at 25 HP so there is no change to the current pump. The extra 7% today or a few hundred dollars will avoid changing the pump, motor, and drive in the future.

The engineer can make an excellent choice today that she can explain will help the owner in the future. Try logging into the B&G program and try overspeeding selections to get comfortable.

We can see real advantages when we use overspeeding selections in this example. Not every pump selection will offer great advantages when in overspeed mode, but it is a tool you should know how to use.

A Quick Notes Before Closing

If you want to see how easy it is to adjust the drive in the field with your B&G pump and a Danfoss or B&G drive watch a video from our Monday Morning Minutes called Adjusting a Variable Frequency Drive (VFD) to Over Speed a HVAC Centrifugal Pump.

Read the Entire How to Pick an HVAC Centrifugal Pump series:

- Part 1: Designing for Owner Satisfaction

- Part 2: Types of Pumps and Seismic Considerations

- Part 3: Mechanical Room Space & Type of Pump Selected

- Part 4: Pump Coupling Types — Close, Split or Flexible Coupled?

- Part 5: Choosing a Single or Double Suction Pump

- Part 6: Internally Vs. Externally Flushed Mechanical Seals

- Part 7: Mechanical Seal MaterialsTags

- Part 8: Motors for HVAC Centrifugal Pumps (Continued)

- Part 9: How to Pick HVAC Centrifugal Pump

- Part 10: Over Speed an HVAC Pump using a VFD

- Part 11: Best Practices for Safety and Performance