Utility, process or heating boiler steam (S), clean steam (CS), and chemical-free steam (CFS) are all options in the steam humidification world. The search often starts with which steam type to use in your building humidifier system. Today we look at the steam quality and the type of humidifier to choose in this R. L. Deppmann Monday Morning Minute.

Three Simple Decisions for Steam Humidification in the Design/Development Stage

The Heat Source

Either you or building codes have decided that steam humidification is a solution belonging in the building you are designing. When steam is the medium used to increase the air stream humidity in the building, there are four simple questions the engineer must answer.

What is the source for the steam humidification production? The power source used to produce the steam will be one of the following:

-

- Existing steam from the HVAC or process system in the building.

- Electricity as a source to produce steam.

- Natural gas as a source to produce steam.

Water and Steam Quality

What is the quality of the existing steam? Assume you have utility or boiler steam available. What is being added to the water in the boiler or steam generator? Are the chemicals or agents being added safe for people to breath in? Is the product being produced in the building affected adversely by those additives? If the steam produced and dispersed in the air is as clean and healthy as the air, you may simply choose to directly inject that steam into the air. This will be the least expensive option in most cases.

If the additives are harmful to people or the process production, you may wish to use a steam-to-steam model (STS) or choose electricity or gas (GTS) to produce the steam for humidification. We will address those models in the next blog.

What is the quality of the water that is used to produce steam? This concern is important when using gas or electric to produce humidification steam. The water quality will affect the type of humidifier chosen as well as the operational efficiency of the unit.

Extremely hard water will require softening in most cases. If the water is 6 grains or harder, some water conditioning should be addressed. Whether the unit is steam-to-steam, electric resistance, or gas-to-steam, hard water will leave deposits that affect the humidification operation. Electric jug-type humidifiers require water to have some hardness for their operation. The tradeoff is water and power consumption.

OpEx vs. CapEx – It’s all about Maintenance

Diagrams courtesy of DriSteem

Humidification level is important in the fight against the spread of disease in buildings. One example of study results is Humidification for K-12 Schools. The use of capital funds to obtain proper humidification levels will reduce the absenteeism of employees and customers or, in schools, students.

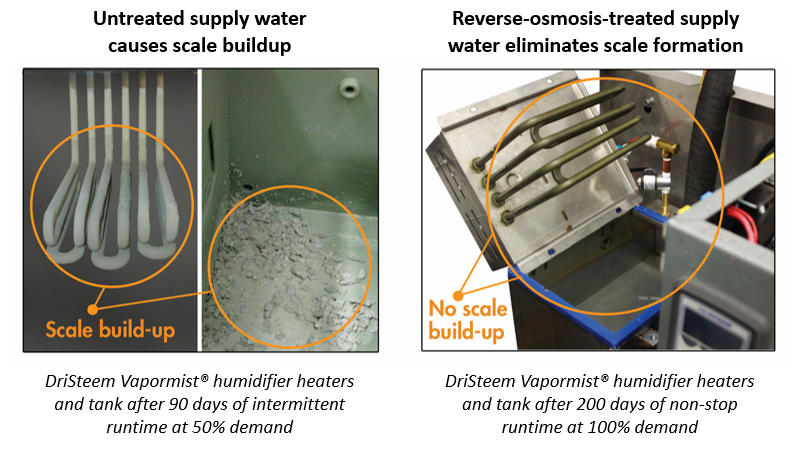

I am amazed at the number of existing humidification systems in buildings that are not functioning. The reason is normally tied to lack of maintenance. Humidifiers will require maintenance. The humidifier may become lost beyond hope if the preventative work is not performed. The type of maintenance as well as the number of hours per season depends on the water quality as well as the type of humidifier purchased.

If the owner voices concern about the lack of maintenance hours available or the cost of outside maintenance, you may consider using a humidifier with reverse osmosis water (RO). The example shown above is extreme. Normal maintenance hours will be 2-4 hours for each humidifier every 3 months during the season. This may be extended if the water quality indicates less is needed. There is also 4-8 hours required at the end of the season. If the RO water is used, maintenance hours will be cut by up to 75%.

The next R. L. Deppmann Monday Morning Minutes will show the DriSteem models for each of the situations described above.