In last week’s Monday Morning Minutes (MMM) post, we offered some rules of thumb about using 100% standby pressure booster systems versus 50%-50% staged systems. So, why do pressure boosters with more lift than friction do better with a 50%-50%-50% system? And why do pressure boosters with relatively constant suction pressures do better with a 50%-50%-50% system? Let’s look at pumping system efficiency and energy.

Pumping System Efficiency and Energy

Energy used is expressed as kilowatt-hours (KWH). The energy used is a result of the VFD input horsepower (IHP). Pump energy is expressed as brake horsepower (BHP). The work performed is expressed as water horsepower (WHP). See the Xylem Bell and Gossett manual TEH-375A for more explanation of these terms.

Let’s look at the water horsepower, which is expressed by this formula:

WHP = (GPM X HEAD) / 3960

Brake and Input Horsepower

The difference in operating costs has everything to do with the pumping system efficiency, motor efficiency, and drive efficiency at the operating point. Brake horsepower (BHP) now adds the pump efficiency into the analysis:

BHP = (GPM X HEAD) / (3960 X PUMP EFFICIENCY)

In a variable-speed system such as our current pressure booster example, the input horsepower is affected by the motor and drive efficiency:

IHP = BHP / (MOTOR EFFICIENCY X DRIVE EFFICIENCY)

It is the combination of pump efficiency over the entire variable speed and control curve range, coupled with the drive and motor efficiency, which determines the cost of operation. We could also include power factor, but we’ll leave that out for now.

Variable Frequency Drive Efficiency

VFDs are very efficient at full speed and remain efficient at most reduced speeds. Danfoss designs and manufacturers their drives with a high quality of efficiency.

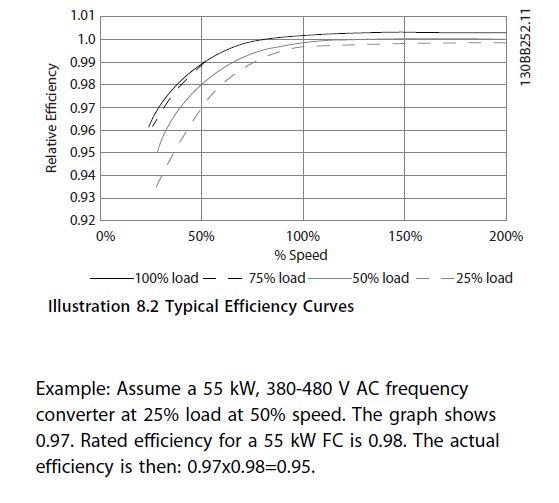

This chart is taken from the Danfoss FC102 design guide. Visit our products page for more information on Danfoss. You can see that the relative efficiency is a multiplier against published efficiency, which is 98%. In HVAC and plumbing applications it’s rare for a drive to operate down below 25% speed because of control head requirements.

Motor Efficiency at Part Load

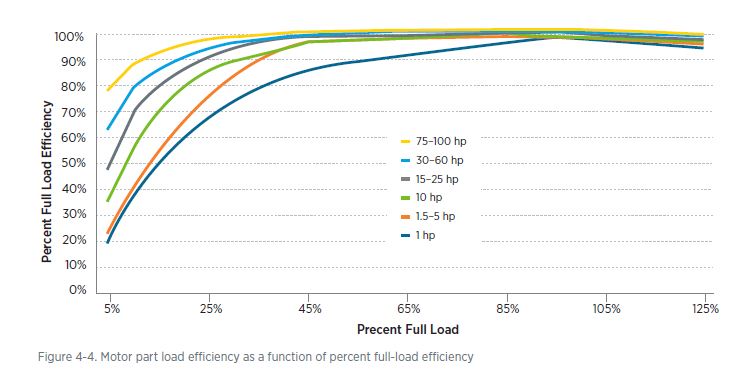

Below is a chart from chapter 4 of the US department of Energy’s Premium Efficiency Motor selection and Application guide. As you can see, the motors remain very efficient until the load or horsepower drops to below 25% of nameplate. In plumbing systems and HVAC systems, this can be a significant amount of the time.

In our example of the university dorm pressure booster, the operation is below 25% of design horsepower for 38% of the time and this assumes no oversizing in the design.

So if we use a 100%-100% pumping system at 40 HP, we will be operating below 25% of nameplate for a much longer time than if we use a 50%-50%-50% pumping system with 20 HP motors:

- If we have a 40 HP total load with one pump and operate at 10 HP, we are at 25% of the motor load.

- If we have a 40 HP total load with two 20 HP pumps and operate at 10 HP, we are at 50% of the single pump motor load and the other pump is turned off.

Based on the charts above, we gain 8% efficiency on motors and 1% efficiency on the drive. This is at lower KWH loads but it adds to the energy saved.

Next week, we’ll finish up by looking at pumping system efficiency and the overarching themes of Domestic Water Pressure projects.

Part One: Capacity Sizing for Domestic Water Pressure Booster Systems

Part Two: Understanding Domestic Water Booster Systems and Discharge Pressure – Part 2

Part Three: Pump Options for Domestic Water Pressure Booster Systems Part 3

Part Four: A Comparison of Domestic Water Pressure Booster Systems Part 4

Part Five: Cost Analysis of Domestic Water Pressure Booster System Capacity Sizing Part 5