In the last two R. L. Deppmann Monday Morning Minutes posts, (MMM) we selected the design and minimum pressures required for a pressure booster system. In this week’s MMM, we look at the number of pumps you might choose to accomplish the job.

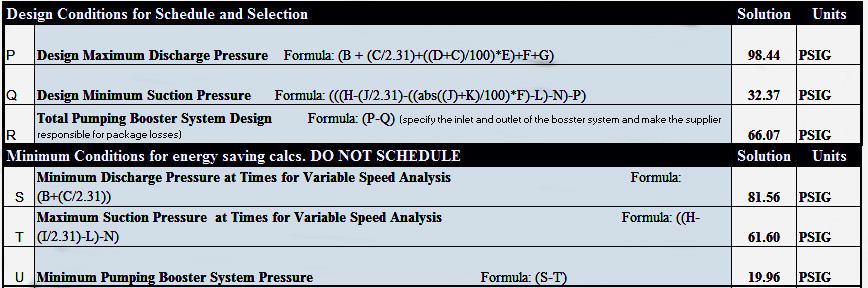

Here is the summary of our example system from last week’s MMM. The table below shows design conditions for selecting the booster system and the minimum conditions at times.

Methods for Determining Flow Rate

There are several sizing methods to determine the flow rate of the system. Three that we recommend include:

- Xylem Bell and Gossett TEH-1096A publication

- The American Society of Plumbing Engineers (ASPE)

- American Society of Heating, Refrigeration, and Air-Conditioning Engineers (ASHRAE)

Once the flow rate is known, the next step is to determine how many pumps are needed.

Pump Options for Variable Speed Systems

With the use of variable speed systems, we tend to default to one of the following choices:

The 50/50 choice

This choice is used most often in plumbing applications. It saves energy since only one pump runs most of the time, and it has less horsepower. It also saves mechanical equipment room space and cost. Also, in most systems, 100% flow rate is rarely required—and when it does occur, it’s for a very short duration. We tend to use this model for residential, apartment buildings, condominiums, and lower cost hotels.

The odds of a pump going down and the flow rate meeting maximum capacity are pretty slim. If the suction pressure is higher than minimum, the parallel pump will run out on the curve and will give you more than 50%.

Questions to ask yourself: Can your client limp by? How quickly can you get the plumber and the parts? NOTE: R. L. Deppmann stocks over $1.5 million in parts and our wholesalers stock even more, so there’s a high likelihood that the parts are readily available.

The 100/100 choice

This option gives you a duplex pump system with one pump able to handle the load at all times and a 100% standby or redundant pump. It should be used when you must have the availability of 100% of the flow at all times. This is a rare case and is mainly used in process production systems and certain healthcare facilities.

The 50/50/50 choice

Now you have the best of both worlds from an operating standpoint. First cost may be higher and it may need a few more square feet of mechanical equipment room space. This system has three pumps, all rated at 50%. Only two are expected to run at any given time and if one fails, the third pump will automatically come on to provide 100% capacity.

The 20/50/50 or 20/40/40 choice

In years past, when most booster systems were constant speed, we used a triplex pressure booster with this capacity split. This gave us a small jockey pump running most of the time to save energy. Today with variable speed systems, there’s little advantage to this split. But occasionally you may find the application, so it’s worth remembering.

Of course you may choose any split you like, but these represent the most common selections we see and recommend.

Next week in the R. L. Deppmann Monday Morning Minutes post, we’ll start to look at some energy cost comparisons.

Catch up on the rest of this series:

Part One: Capacity Sizing for Domestic Water Pressure Booster Systems

Part Two: Understanding Domestic Water Booster Systems and Discharge Pressure – Part 2