External water treatment in cooling tower systems will save labor and operational costs. It also saves the planet by reducing your clients’ dependance on chemicals that go down the drain and into the earth’s water supply. How does the engineer specify external water treatment so their client can enjoy these savings? Today we look at an example of external water treatment.

Cooling Tower External Water Treatment Package

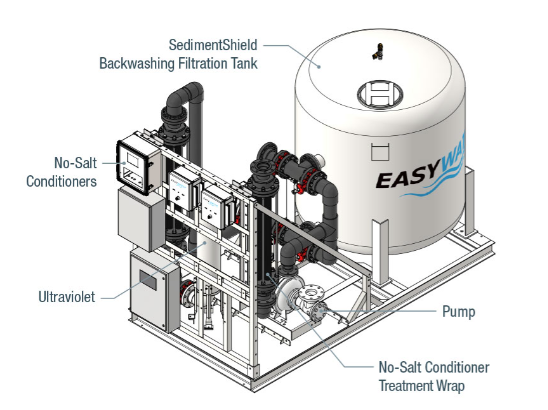

A properly designed cooling tower treatment system should include the three components mentioned in the Open Cooling Tower Systems — External Water Treatment Options article you may have read two weeks ago. They are the filter, the ultraviolet light, and the electromagnetic softener. The side stream package should also include the pump, interconnecting pipe, and the controls. EasyWater is a company that provides this and other treatment solutions. Our Water Solutions Group represents this product. Today, we offer an example system and an opportunity for the engineer to learn more.

Example Cooling Tower System External Water Treatment Solution

We begin by selecting an example cooling tower system. Assume that we have a 1000-ton cooling tower system. We would like a side stream water treatment package that includes the items mentioned above.

This package system is easy to show on the plans as well as easy to specify. It is possible to purchase all the components separately but by specifying the package, you gain unit responsibility. You also know that it is professionally assembled. In a 1000-ton cooling tower system, the manufacturer would recommend a side stream package at 5% of the total flow. Most cooling tower systems use three GPM per ton so our 1000-ton tower system will have a 3000 GPM flow rate. Five percent of that 3000 GPM will be 150 GPM as the basis for our CTF system. We look at the EasyWater® packages and choose a model CTF-150-S. What does the package include?

-

The Filter

The EasyWater® Sediment Shield filtration system boasts a sub-micron exceptional design filter which gets down to the micro level which sand filters cannot reach. In addition, their filter system requires significantly less maintenance than other brands on the market.

The maintenance required on this filter is to check for the alarms once a week and replace the battery every five years. This is the filter that saves on maintenance time and costs.

-

The Ultraviolet Bacteria Removal System

The UV light in the CTF system will eliminate the bacteria as described in the last Monday morning minute. The only maintenance required is occasional replacement of the bulbs and the location and connections in this package make that a quick change.

-

The No Salt Electromagnetic Conditioner

The No Salt electromagnetic conditioner performs the important task of keeping the pipe and valves clear of precipitation.

The chemical free treatment causes the tree branch minerals to cling to each other and lose their electric charge.

The TWS spool wraps are external to the pipe which results in no regularly scheduled maintenance requirements. The engineered treatment solution has a normal service life of 10 to 15 years.

-

Weatherproof Panels

The system includes the operating pump and starter panel. The multiple panels provided are weatherproof and include a single disconnect for the package. Our example system, the CTF-150-S, is available for 208-230/460 volts.

The panels include simple, easy-to-read diagnostics. The system includes dry contacts for alarms. and BACnet communication may be added as an option.

See for Yourself Case Study Video

We offer one example of the benefits of using a packaged external water treatment solution from EastWater®.

Save the Planet

The CTF external water treatment system saves more than maintenance labor and chemical product costs. This system will reduce your chemical use and the associated chemical waste to the environment. A typical system can reduce the chemical use by about 80%. You still should use some oxidizing biocide such as chlorine or bromine but even those chemical quantities can be reduced.

An Offer for Engineers in Michigan and Northern Ohio

Water Solutions Group makes the following offer to engineers in our territory: we would like to provide a suggested external water treatment solution for a system you are currently designing with cooling towers. Why not see what the alternative to chemicals looks like on your project? No commitment on your side except the time to review a better solution for your customer. Simply fill out the form below to get started!

If you are reading this and do not have the benefit of being in Michigan or Northern Ohio, fill out the form and we will forward it to the solutions group in your area.

Cooling Tower Water Treatment Consultation

For engineers that are currently designing a system with cooling towers, Water Solutions Group will provide an external water treatment solution for you to review and discuss with your client. Simply provide your name, company name, contact email, phone number (optional), and a project name we can reference in the form below and a team member will be in touch shortly.

Water Solutions Group offers innovative water quality solutions for cooling tower systems.

Water Solutions Group is a separate division of the R.L. Deppmann Company created to provide end users and engineers with a valuable resource in efforts to improve water quality. Proper water quality management protects the equipment, operations, occupants, and environment. Water quality should be considered at the time of design to ensure safe and efficient operating systems. Our intimate knowledge of water systems positions Water Solutions Group to be the ideal partner when evaluating operational issues that may arise because of poor water quality.