The design and flow balance in systems with multiple parallel condensers is straight forward. We should expect no issues at full capacity. What happens when your system is using a single pump, single condenser, and single tower operation? Often, the actual flow rate is more than the design flow rate.

The design and flow balance in systems with multiple parallel condensers is straight forward. We should expect no issues at full capacity. What happens when your system is using a single pump, single condenser, and single tower operation? Often, the actual flow rate is more than the design flow rate.

How do we protect pumps, cooling towers, and condensers from the problems caused by excessive flow? We offer three solutions.

The last several R. L. Deppmann Monday Morning Minutes addressed the concern of excessive flow rate during single chiller/condenser operation. If you need to catch up, links to previous articles in this series are shown at the end of this post. The issue identified is the flow rate of a single operating pump and condenser.

The Single Pump Issue Presented for Multiple Constant Flow Condenser Pumps

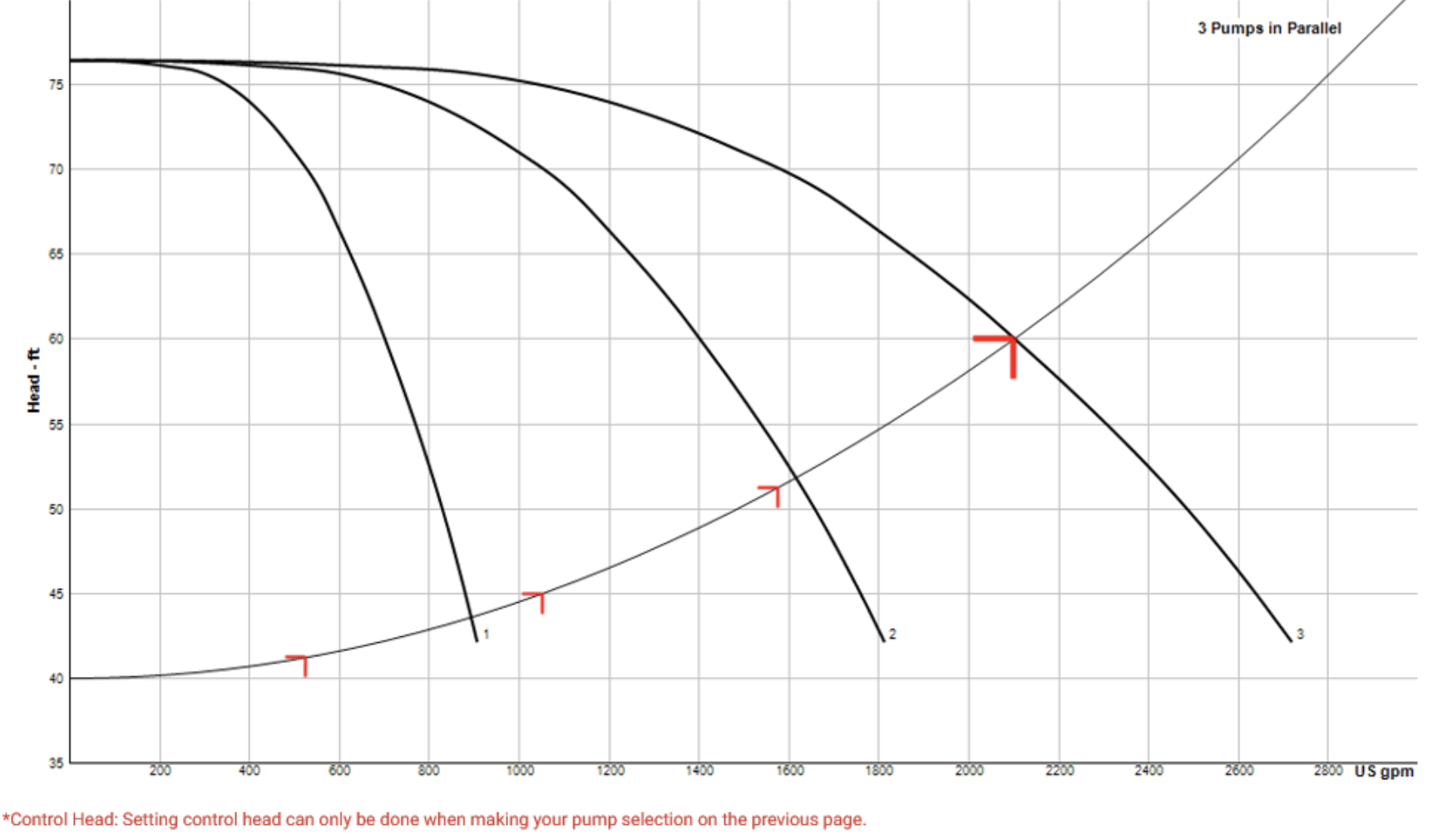

The system previously examined is shown below. The design flow is 2100 GPM with three pumps in parallel. The single pump, condenser, and tower would be designed for 700 GPM. Once the system is balanced for three pump operation, the single pump operation will run out on its curve. The single pump flow rate would be about 880 GPM.

Here are three potential solutions if the 880 GPM is too great for the equipment being served.

Solution #1: Variable Speed Drives for Constant Flow Condensers

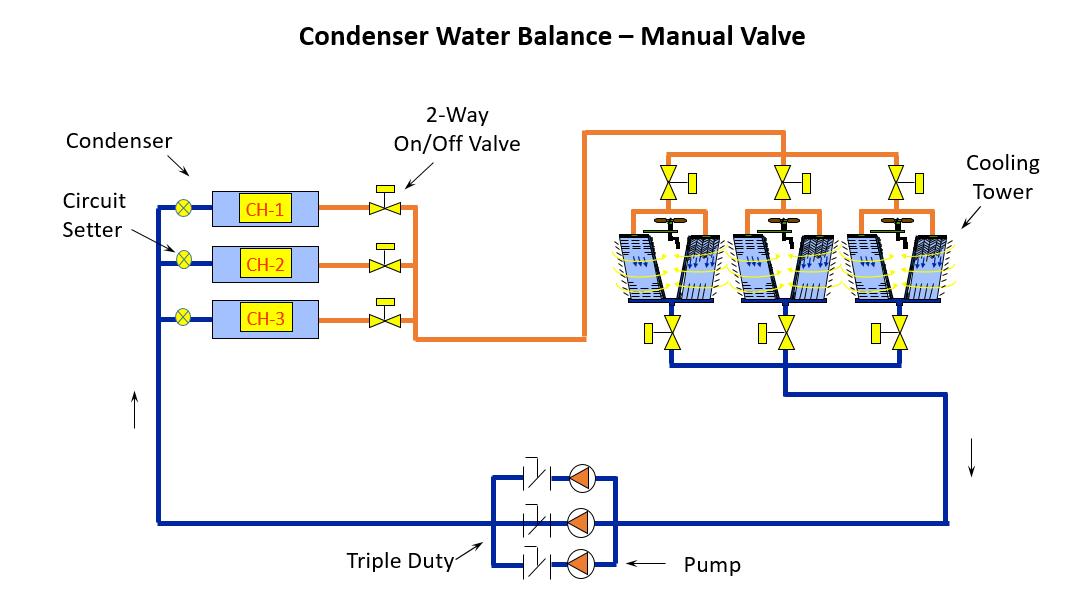

We suggest variable speed drives instead of starters. The drives on the pumps would respond to the same enable signal for the need of a condenser and tower online. The drive(s) would control the speed of the pump or pumps to maintain the differential required across the condenser header.

The goal is to maintain 700 GPM through a condenser when it is on and it’s two-way on-off valve is open. Whether one chiller or three chillers are operating, we know the fixed pressure drop at that flow rate. It is the condenser, balance valve, and condenser piping pressure drop. In the example, it is 40 feet.

Since we have variable speed drives, we can open the triple duty valves. This will save energy. As the strainer plugs with dirt, the differential across the condensers will drop and speed up the pump to maintain flow rate. We now have automatic fixed flow rates as the strainers plug. The controls can provide notice if the pumps ever get to a higher speed to indicate it is time to clean the strainers.

Solution #2: Flow Limiting Balance Valves for Constant Flow Condensers

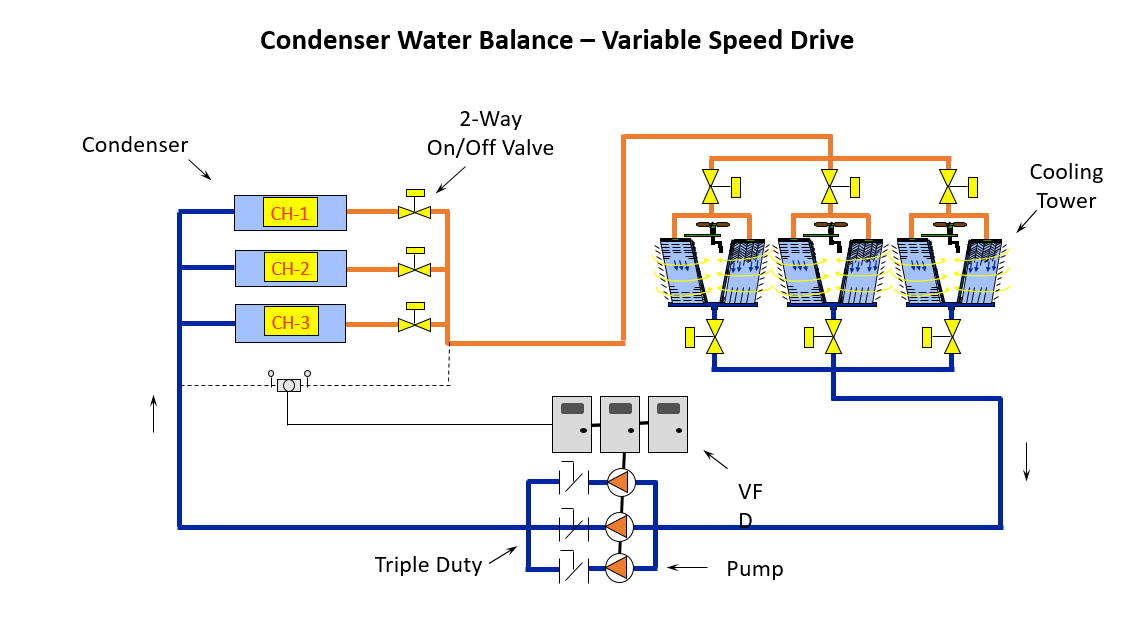

The second solution would use flow limited balance valves instead of manual balance valves at the condensers. This solution would use constant speed operation.

These valves are supplied by Griswold Controls or Bell & Gossett. These valves will vary the orifice area to maintain the rated flow rate. They may have a higher pressure drop then the manual valves so care should be taken to keep the minimum pressure drop low. In our example of 700 GPM, either of the following will work. Griswold model 3373AT-8” wafer valve will have a pressure drop of 6 feet at design flow. The Bell & Gossett model WV-8”-700 will have a pressure drop of 12 feet.

The advantage of these valves is a lower installed cost than solution #1 and a simple flow balance. The disadvantages are the extra pressure drop, more operating cost than solution 1, and more concern about water quality with the smaller passageways in the valves.

Solution #3: Manual Balance Valves and Modulating On-Off Control Valves

This solution works great when the pumps are operating at constant speed. Keep the circuit setters as the balance valves and change the on-off two position control valves using a pre-set limit control strategy which will drive valves to a balanced position depending on the number of condensers online.

In the example above, the valves will be full open with all three condensers online. With two chillers on, the valves will throttle to provide 12’ of additional pressure drop. When one condenser is online the valve will be re-positioned to provide 17’ of pressure drop.

The advantage of this solution is less concern about the quality of the water. Another advantage is the return to the original pump head using manual balance valves. There is also a lower installed cost than solution #1. The disadvantage is the cost of the control valves requiring four positions and the control involvement in signaling the valve position.

R.L. Deppmann will assist our customers in selection of these solutions for their multiple condenser-tower projects.

Next week, we will complete this series with a look at the costs of these three solutions. To catch up, see the previous articles below:

- Part 1: Selecting Constant Speed Cooling Tower Pumps & Balance Valves with Multiple Condensers

- Part 2: Balancing Constant Speed Cooling Tower Pumps with Multiple Condensers