This service tip of the month is a quick start guide to setting up the built-in sequencing controls in Aerco Benchmark boilers with C-More controllers. This built-in boiler sequencing technology (BST) that is standard on every Aerco Benchmark boiler has many features to limit cycling and get the highest possible efficiency from the heating plant.

For reference purposes and menu structure questions, please use this link to be taken to the start of the C-More controller menu section of the boiler IOM.

Before Applying Power

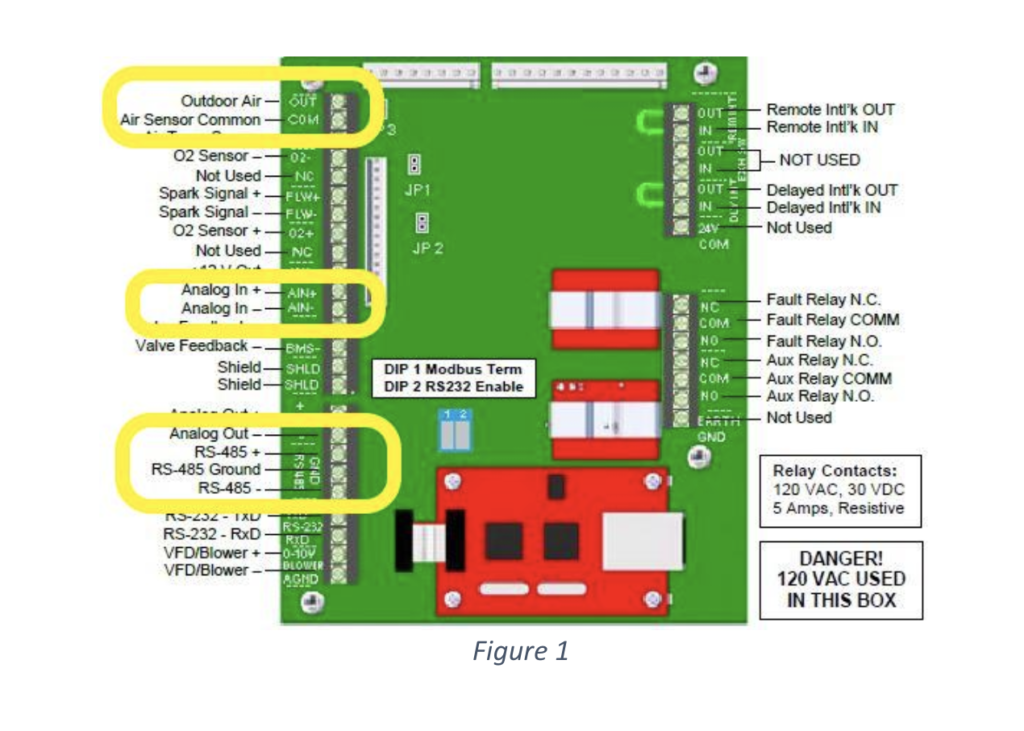

- Daisy chain all boilers using Shielded 2 conductor wire to each boiler on RS485 terminals.

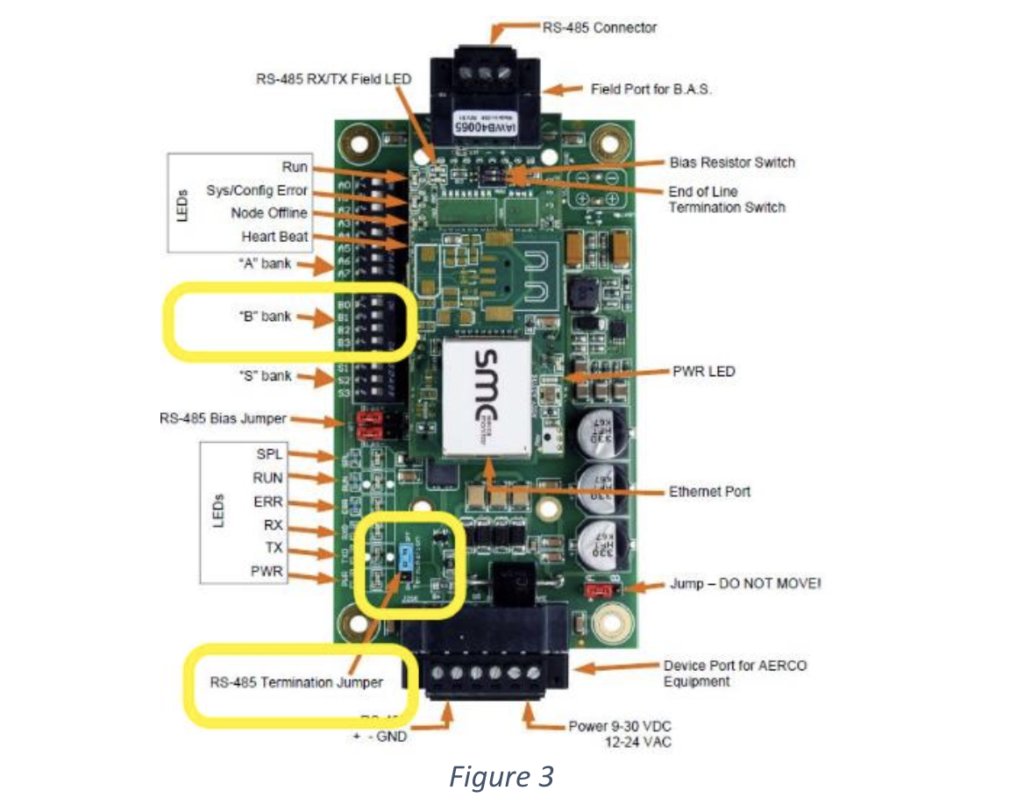

- If using a Protonode, start Daisy chain at Protonode, then boiler 1, boiler 2, Etc. See Figures 1 & 3.

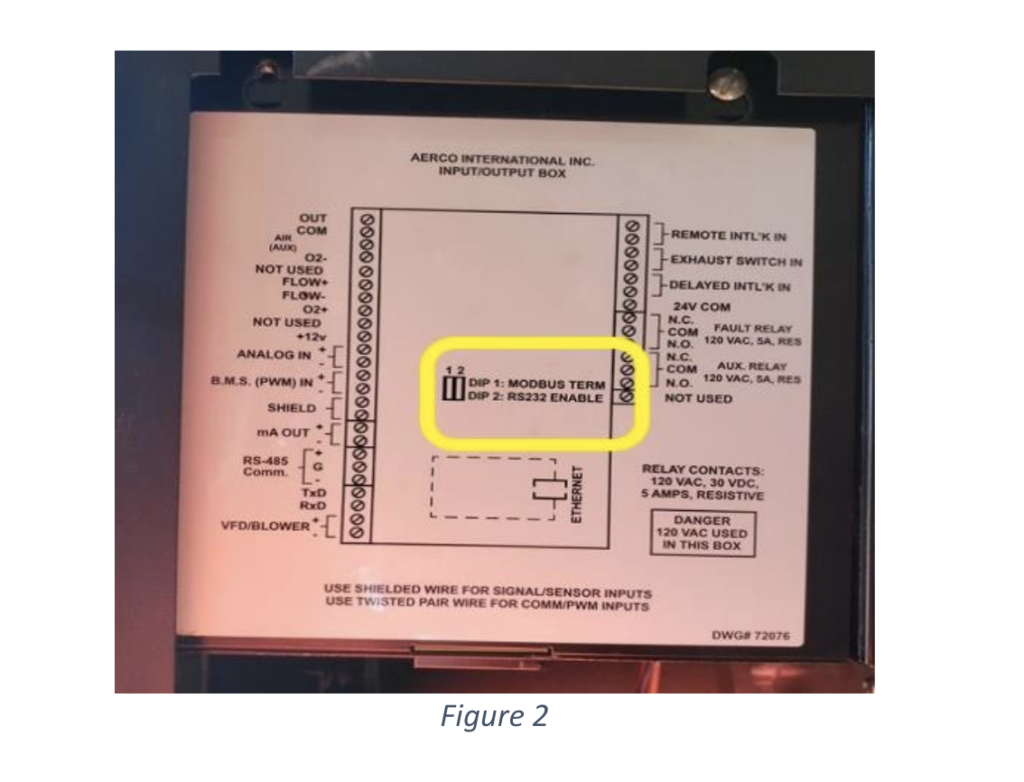

- Turn on Modbus termination switch on I/O board on the first and last boiler in the daisy chain. See Figure 2.

- If using a protonode, do not terminate boiler 1. Instead, move termination jumper in protonode to on position. See Figure 3.

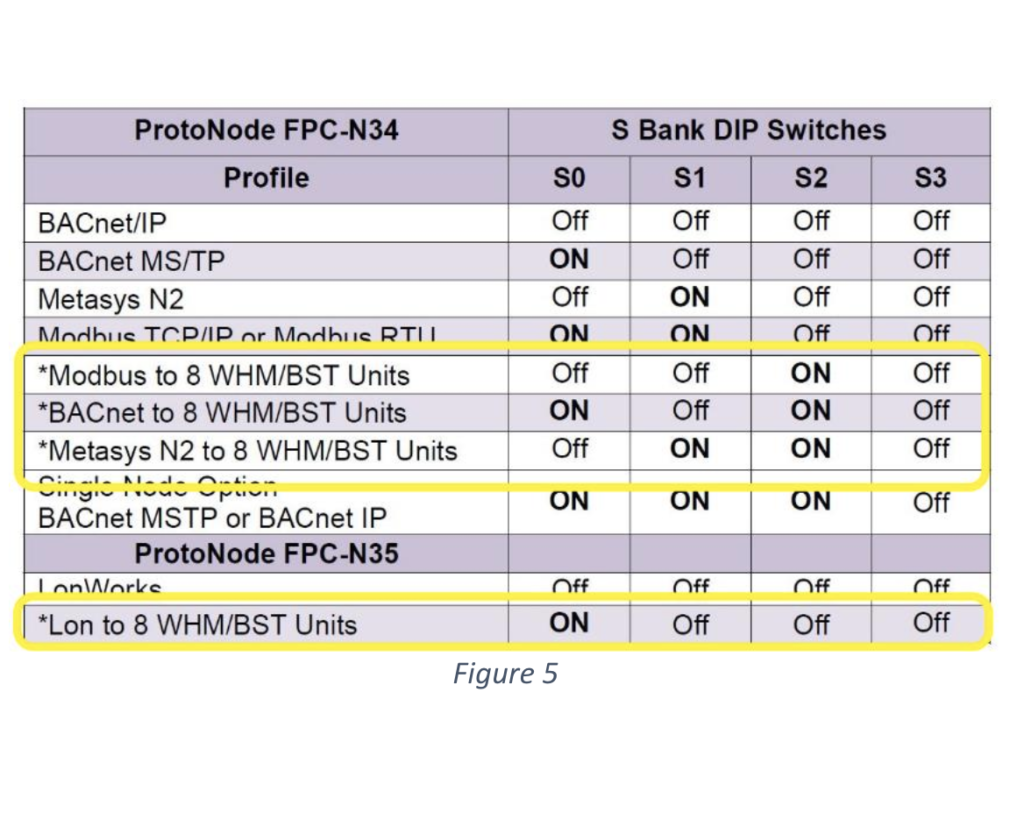

- Set Profile dip switches (B bank) as needed to match building automation protocol. See Figure 5.

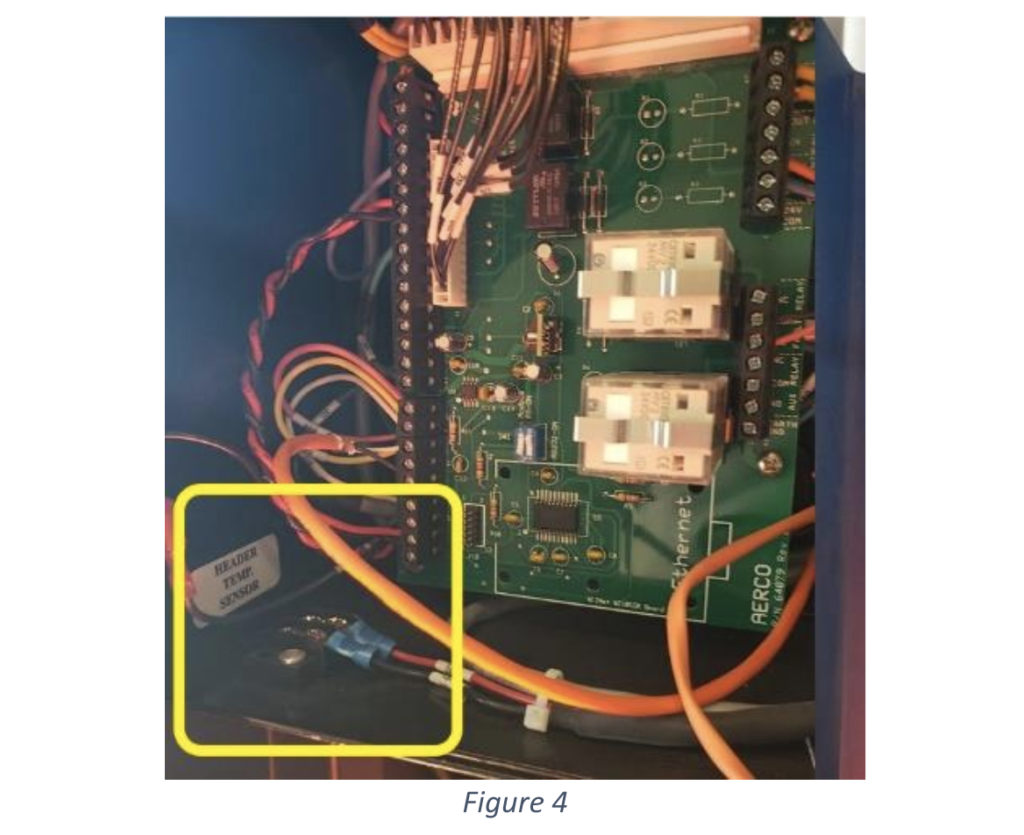

- Wire Header sensor (See Figure 4) to the terminal strip and outdoor sensor (See Figure 1) (if using outdoor reset) to I/O board of managing boiler.

- Plug-in Isolation valves (if installed) to prewired whip supplied in the boiler.

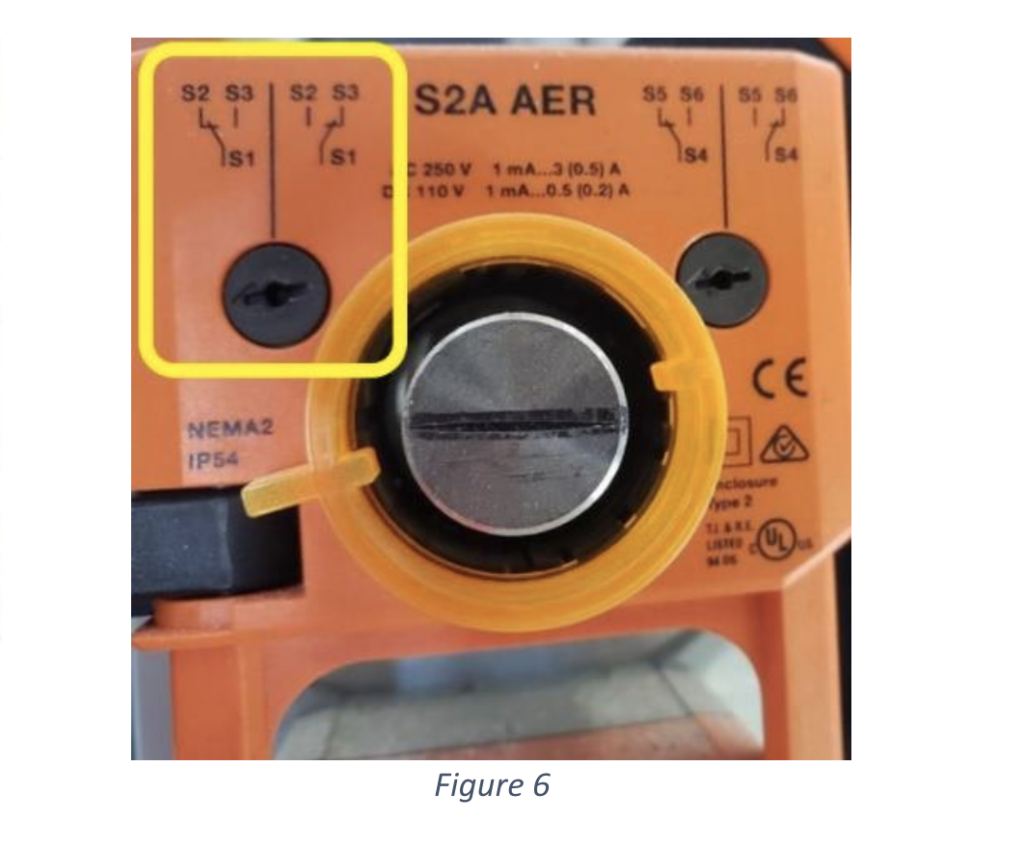

- Set End switch on the Isolation valve as pictured below. When the valve is open, the end switch S1-S2 should be pointing to 9 o’clock. When the valve is closed-end the switch should be at 3 o’clock. See Figure 6.

|

|

|

|

|

|

Menu item changes for Boiler Sequencing Technology Setup

On all boilers

Setup Menu

- Enter Password 6817

- Set Comm address. Can be addressed 1-8. Cannot use 0 as an address. Each boiler must be addressed differently.

Configuration menu

- Aux start on delay – set to 120 seconds if Aerco isolation valves are used.

- BST menu – Set to Enabled

BST Menu

- BST Mode – Set all boilers to Client (*for now)

On Managing boiler only

BST Menu

- BST setpoint – used if boiler plant is set at constant setpoint, also a failsafe if building automation loses its remote signal.

BST Operate Menu

- Change BST max boilers to actual number of boilers onsite

BST Comm Menu

- Change min address to 1, and Max address to highest address onsite (up to 8)

- If using a Protonode, Change SSD address to 247, and SSD temp format to Points

BST Setup Menu – choose 1 of 3 options for BST Setpoint Mode

- Constant setpoint

- Boiler plant will only maintain the loop to what was set at BST setpoint.

- Remote setpoint

- Building automation sends a 4-20 ma signal to analog in terminals of I/O board

- In BST Temp control menu, change setpoint low limit and setpoint high limit to match building automation temperature scale. 4ma=low setpoint limit 20ma=high setpoint limit.

- Outdoor reset

- In BST Temp control menu set BST Ref Temp, BST Reset ratio, and System start temp (warm weather shut down) as needed per charts in boiler manual (GF-206 Appendix E)

*When all settings are changed, switch the Managing boiler from BST client To BST manager.

Please contact R.L. Deppmann for any questions or your Aerco needs.