It is important to check the single pump operation when balancing parallel pumps for multiple constant speed cooling tower pumps. The condensers and pumps are balanced, as normal, at full capacity. The new spin is the check of a single pump operation and proper settings at that condition.

It is important to check the single pump operation when balancing parallel pumps for multiple constant speed cooling tower pumps. The condensers and pumps are balanced, as normal, at full capacity. The new spin is the check of a single pump operation and proper settings at that condition.

Multiple Constant Flow Condenser Pumps and Head Loss

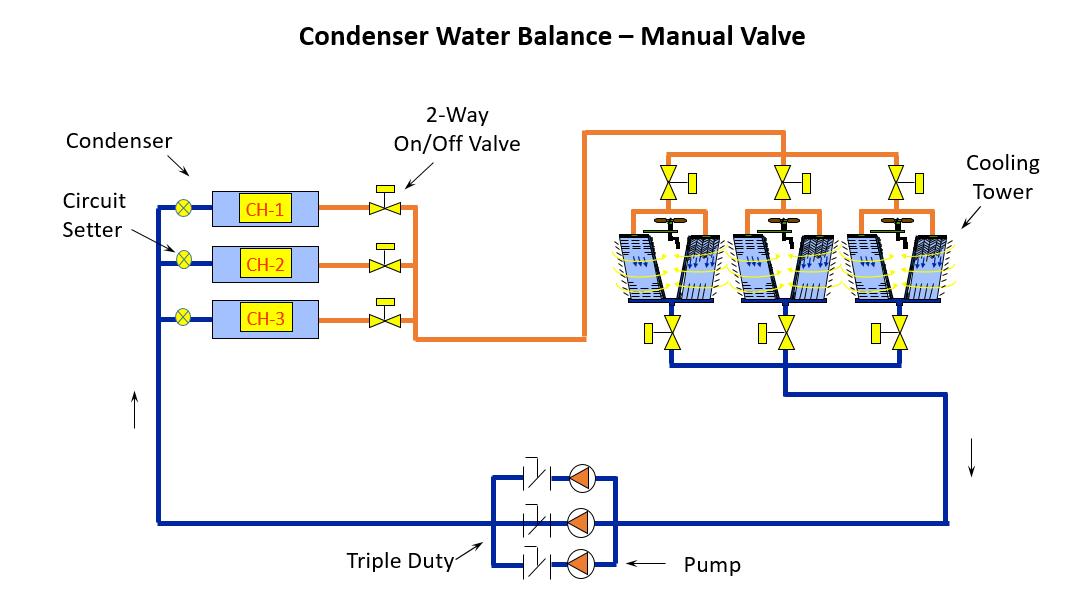

Here is a representation of a sample multiple tower and condenser system.

There are three condensers and three parallel piped pumps. We will assume all three can operate. Each pump is rated for 700 GPM design flow rate with a B&G 3DS-6B triple duty valve. The pump head will be 60 feet.

System Balance with Multiple Condensers with Manual Balance Valves

Starting the Pumps

- With all pumps operating and flow rate to all three towers and condensers, throttle the pump discharge valves by 50%.

- The assumption here is that there will be excess pump head. I like to start at the pumps to avoid possible cavitation and pump problems during the balance.

Balance to Design Flow

- Read the B&G circuit setter balance valve on the farthest chiller. Open the pump discharge valves until this condenser is at 105% of design flow rate. (735 GPM in our example).

- If the balance is set at 5% more than the design flow rate, there will be some allowance for plugging of strainers during tower operation. In our example we will end up at about 2200 GPM.

- Read the circuit setter on the next closest condenser. Throttle this balance valve to the design flow rate plus 5%. (735 GPM in our example)

- Throttle and readout the closest condenser balance valve. (735 GPM in our example)

- Continue the balance at the tower inlet valves. Adjust the pump discharge valve if needed.

Verify Flow of Single Condenser

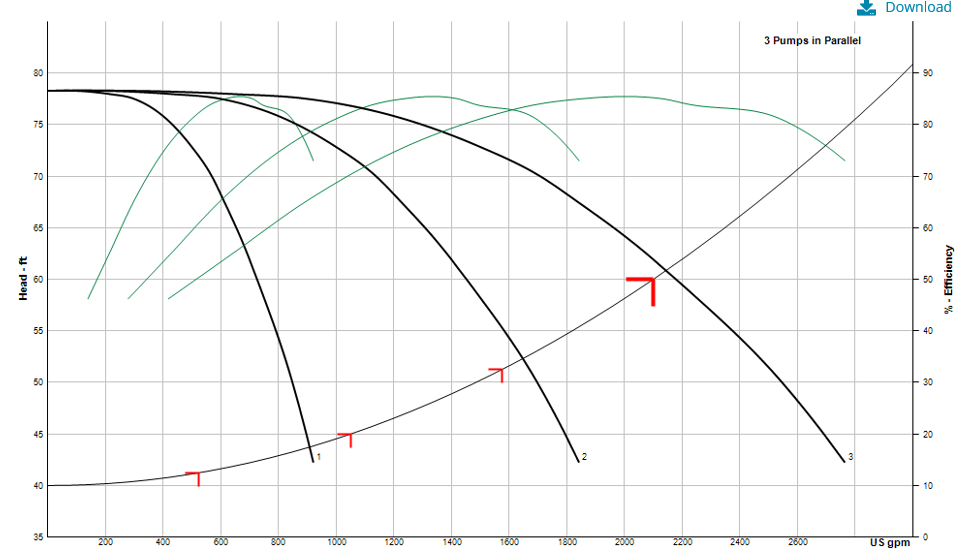

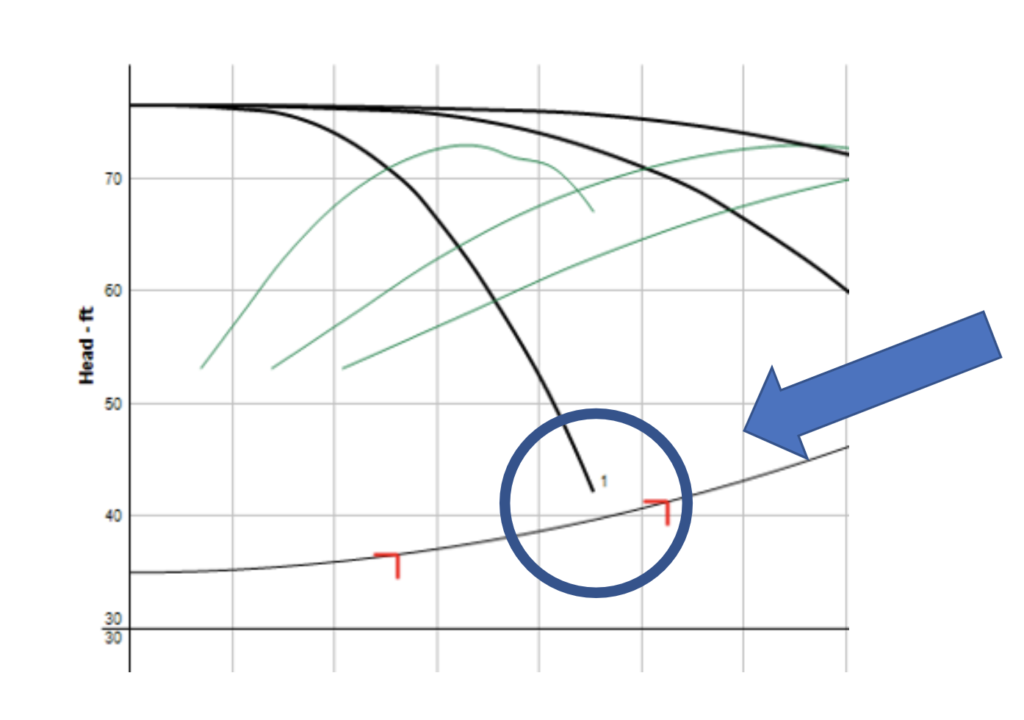

The system should now be in proportional balance with excess head across the triple duty valve. Now we will check the single pump operation to identify if the operation is on the published pump curve.

- Close off two towers, two pumps, and all but the closest condenser. The idea here is to get the operation of a single pump, condenser, and tower with the least pump head.

- Read out the flow and suction and discharge readings of the pump. There are two concerns here. First, it will identify if this operation is on the pump curve. Second, it will identify the flow rate to determine if it is excessive for any of the system components. Record the pump readings and flow through the condenser and include it in the report.

Concerns to be Addressed

This flow rate may be too great for the tower and condensers supplied. The pump suction pressure may be too low for the net positive suction head (NPSH) required. Someone will have to make that call. If the flow rate is too great, some means of reducing the single condenser flow rate will be employed.

We will address the options during the next R. L. Deppmann Monday Morning Minutes.