When using multiple parallel condensers with constant speed pumps, the flow rate at part load may be excessive and problematic. Our last blog on this subject identified three solutions to the excessive flow problem. Today we complete this series by looking at the operating cost of the pumping system for each of the three solutions.

When using multiple parallel condensers with constant speed pumps, the flow rate at part load may be excessive and problematic. Our last blog on this subject identified three solutions to the excessive flow problem. Today we complete this series by looking at the operating cost of the pumping system for each of the three solutions.

The Concern of Single Pump Operation for Multiple Constant Flow Condenser Pumps

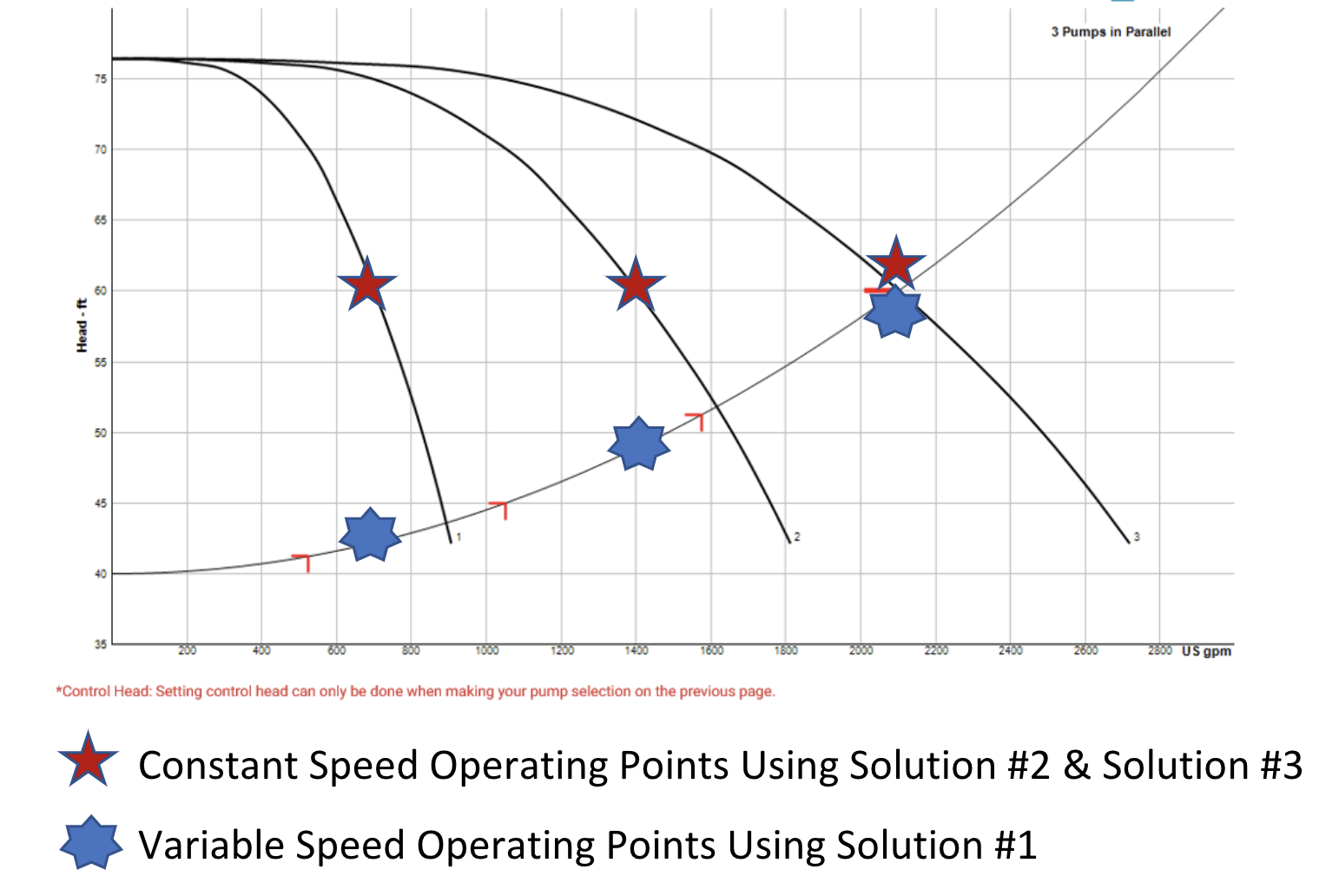

The system previously examined in the R. L. Deppmann Monday Morning Minutes are shown below.

The design flow is 2100 GPM with three pumps in parallel. The single pump, condenser, and tower would be designed for 700 GPM each. Once the system is balanced for three pump operation, the single pump operation will run out on its curve. The single pump flow rate would be about 880 GPM.

We identified three solutions:

- Solution 1 is the addition of variable speed drives with a sensor.

- Solution 2 was to replace the manual balance valves with constant flow limiting balance valves.

- Solution 3 was to convert the 2 way on-off valves to a set position based on the number of pumps.

You may review the solutions in more detail here.

The Solutions Previously Presented

The system used as an example has three pumps with extra pump head that was added as a safety factor and is throttled across the balance valves.

- Solution 1 is the addition of variable speed drives on the tower pumps to control the speed based on the differential pressure across the condenser header.

- Solution 2 keeps the constant speed pumps but adds flow limiting balance valves to eliminate the excessive flow concerns.

- Solution 3 also eliminates the excessive flow concern by using the on-off control valves in various throttled positions.

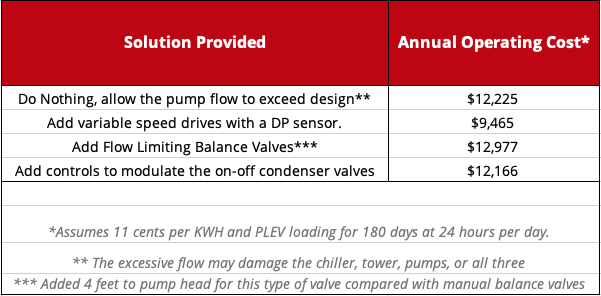

The Condenser Water Load Profile Used

We used the B&G PLEV or part load efficiency value load profile for the cost analysis. This profile uses; 100% flow for 1% of the time; 75% of the flow for 42% of the time; 50% of the flow for 45% of the time; and 25% of the flow for 12% of the time. The condensers are constant flow devices, we would need 3 condensers operating to achieve the 75% portion of the load. If three chillers are operational for less time, Solution 1 with variable speed will use significantly less energy. This is a conservative look at the energy.

The Operating Costs (in this example)

The return on investment (ROI) could be as high as 2 to 4 years based on the load profile and the reduction in components needed to meet the required part load flow rate. This does not even include the time saved in checking strainers and possible damage due to over pumping. The application of Solution 1 with variable speed drives in multiple chiller systems should be something the engineer reviews.

Using the Bell & Gossett esp-Systemwize will help identify operational points at part load conditions. As always, R. L. Deppmann Company or your local B&G representative may help you with questions about this topic or the use of the software program.