What is the minimum flow rate a variable speed pump can provide without damage to the pump? This is a question every engineer should ask themselves when designing a variable flow heating or cooling system. We received a call from a well-informed control contractor, and it offered me a chance to define a step-by-step process for determination of minimum flow.

The Issue: A Hospital Requires Chilled Water in the Winter

The inquiry from the control contractor was the result of a request from a large Michigan Hospital. They had a chilled water system designed to operate in the summer but now wanted to use it for some small loads in the winter. The Bell & Gossett 1510 end suction base mounted chilled water pump and the B&G VSX double suction base mounted pumps will be re-used. The contractor is an engineer and I know him from the many R. L. Deppmann seminars he has attended. Here is the request:

“We’ve been looking at min flow on two existing B&G pumps. Given the recent Monday morning minute (September ’21) on this topic, I thought you might be willing to help and give your opinion on this. We just need to be confident we can use these pumps to safely handle the reduced flow for the entire winter as the primary cooling source for MRI equipment. Reduced flow requirements are between 130 and 150 GPM for the 1510 5G and ~375 GPM for the VSX pump. Existing pumps are as follows:

1. Existing Chiller Evaporator Pumps – 1510 5G, 11.25, 1800 rpm, 40 hp

a. Current Design (summer) – 1115 GPM @ 90’ TDH, variable speed with current control setpoint @ 25’.

b. Proposed future winter mode is quite a bit less flow with slightly higher control setpoint of ~33’.

2. Existing Chiller Cond Pump – VSX-VSC 6x8x13.5A, 11.125,” 1800 rpm, 75 hp

a. Current Design (summer) – 2053 GPM @ 90’ TDH, current control setpoint is ~25’

b. Proposed future winter mode is quite a bit less flow with slightly higher control setpoint of ~42’. Variable speed driven.”

Determining the Minimum Flow Requirement of the Pump

First, the pumps are under 100 HP. If they are over 100 HP, I recommend checking B&G to make sure the Hydraulic Institute (HI) default of 20% of best efficiency point is adequate. Also note that this point of operation is intermittent and not continuous constant flow. That gives some “wiggle” room if you are close.

Here are the steps:

Step 1: Find the pump curve. Use the Bell & Gossett esp-Systemwize program and find the curve. Run the program choosing variable speed for the existing or design capacities Use the control head required for the expected low flow condition. In this example, use the new control head. Select the existing pump from the choices.

Step 2: Change the impeller to the existing size. Some variable speed selections will use the largest impeller with non-overloading characteristics for the selection and trim with a lower speed. If this is a new selection, keep the impeller the program suggests. If it is an existing pump, change the impeller to match the existing.

Step 3: Determine the minimum speed at the control head with 0 GPM. You can go into the program and add speeds if you need another speed curve for this step.

Step 4: For the lower speed shown in step 3, determine the flow rate at best efficiency point (BEP) for that speed curve.

Step 5: Identify 20% of that BEP flow rate from step 4 and that is the minimum HI suggested flow rate.

Here is a short video showing the steps for the chilled water pump shown above.

Why don’t you try determining the minimum flow on the condenser water pump yourself? In fact, send your answer in and R.L. Deppmann will select three random names with the correct answer to receive a small Bell & Gossett prize!

Submit answers here.

Need More Information?

If you are not sure why minimum flow rate is an issue or want to learn more, visit the following R. L. Deppmann Monday Morning Minutes.

Minimum Flow in Variable Speed Pumps for Building Hydronic HVAC Systems (Part 1)

Minimum Flow in Variable Speed Pumps for Building Hydronic HVAC Systems (Part 2)

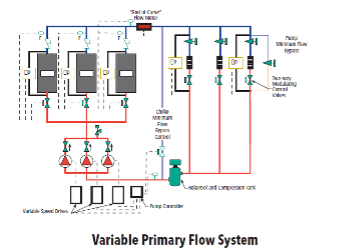

Solving Minimum Flow in a Primary Variable System (Part 3)

Minimum Flow in Variable Speed Pumps for HVAC and Building Plumbing Systems