In the last three RLD Monday Morning Minutes, I made the case for a pre-pressurized tank in variable-speed pressure booster systems. Today, let’s look at the minimum and suggested size of the tank.

To determine the booster system pump head, look at the discharge pressure required minus the suction pressure required plus package friction losses. The pressure on the discharge of the package is:

Booster Pump Discharge = Fixture pressure + Elevation + Discharge friction loss

When there’s no flow, we still need to create enough pressure to lift the water and maintain the pressure needed by the fixture. Bell and Gossett designs and manufactures several pressure booster systems. These systems use sensorless design and remote sensor design, as suggested in the 2013 version of the ASHRAE 90.1 standard. They can also be used with the traditional discharge mounted sensor.

Regardless of control, the booster system follows an algorithm to slow the pump down to the minimum speed that will still create the minimum pressure required. Once satisfied, the pump is shut down to save energy.

As identified in Part 3, water is incompressible. So the second that any water is used, the pressure will drop. Because of this, we need a tank. What is its pre-charge pressure and what is its drawdown or acceptance volume?

Drawdown Volume

The drawdown volume, or acceptance of the bladder tank, has to be enough water to satisfy demands during the 15 seconds it takes for the pump to come up to speed. This is a guess, but in most systems, it’s a very small number. The engineer can estimate this number or just use a couple of gallons. Another option in a system with normal usage is to use the work Bell and Gossett has already done for us.

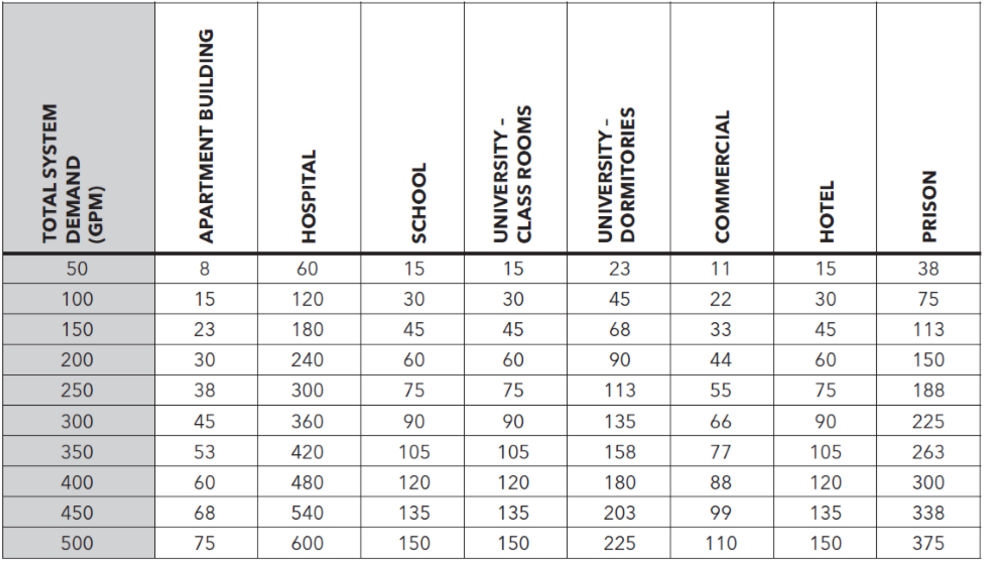

The B&G technical manual TEH-1096A gives recommendations for a storage volume for 30 minutes based on system demand (figure 5.4). If we simply take 10% of that number, it should be a small storage amount and satisfy the instantaneous load in a normal system.

Let’s look at the example system we’ve been using, an apartment building with a 200 GPM total design flow rate. In chart 5.4, the storage required for 30 minutes is 30 gallons. 10% of that number is 3 gallons of storage required. It may be more than is actually used but, it’s still very small. We need a drawdown of 3 gallons from the time the system starts until it comes up to the speed needed for pressure.

Tank Pressures

In a constant speed system with the tank on the discharge header, the tank maximum pressure is the design discharge pressure. There are rules of thumb that say to charge the tank at 10 PSIG less than the maximum pressure. In reality, the charging pressure should be the minimum pressure. But in a variable speed system, we just stated that, ideally, the booster system discharge pressure drops to the minimum before it shuts off. This leaves no pressure difference in the tank and no volume.

Since we need some storage, I recommend a minimum of 5 PSIG between tank charge and minimum pressure. Make the minimum pressure of the booster, the point the booster shuts down, at 5 PSIG more than you need. This will allow some pressure difference (5 PSIG) in the tank. Water can leave the tank on a tank flush or lav opening. Once the booster shuts down, the pressure will drop to the minimum while the small volume of water leaves the tank.

Example System

Let’s look at an example. Let’s say our apartment example has a lift of 100 feet (43 PSIG) and a minimum fixture pressure of 35 PSIG. If we assume the tank is at the booster system discharge, the minimum pressure is 43+35= 78 PSIG. We set the booster to shut down at 83 PSIG and we charge the tank to 78 PSIG. If the tank is located right at the fixture at the top of the system, the tank would be charged to 35 PSIG with the booster shut down still at 83 PSIG.

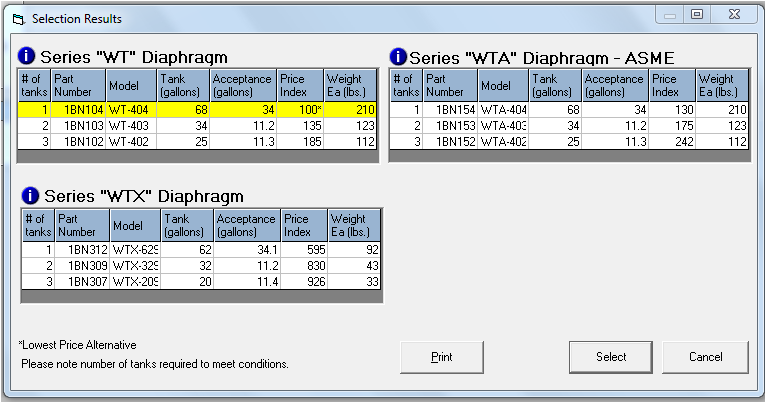

In our example we need at tank with a minimum pressure of 78 PSIG and a maximum of 83 PSIG while drawing down 3 gallons of water. Using the B&G hydropneumatic tank sizing program, we get the following results.

We could use a B&G WTA-404 ASME tank or one of the non-code choices. The ASME tank would have a 68-gallon volume with a maximum acceptance of 34 gallons and a drawdown of 3 gallons.

If this seems confusing, come back for next week’s Deppmann Monday Morning Minute!