The State of Michigan is very specific in codes regarding sump pumps located in hydraulic elevators. Our latest and updated R. L. Deppmann Plumbing website includes a section on these sump pumps. Today’s Monday Morning Minutes will offer the engineer a clear description and a link to a tool for simple detailing and specification to meet the code.

The State of Michigan is very specific in codes regarding sump pumps located in hydraulic elevators. Our latest and updated R. L. Deppmann Plumbing website includes a section on these sump pumps. Today’s Monday Morning Minutes will offer the engineer a clear description and a link to a tool for simple detailing and specification to meet the code.

Sump Pump Flow Rate Capacity in Elevator Pits

ASME has a safety section dedicated to elevators and escalators. Section A17.1 2.2 indicates “… all elevator pits for elevators that have Firefighters’ Emergency Operation, be provided with a drain or sump pump. The pit drainage shall be designed to remove a minimum capacity of 3,000 gallons per hour per elevator car.” So, each elevator must have a pumping capacity of 50 GPM. One shaft with one elevator will require 50 GPM. One shaft with two elevators will require 100 GPM.

This will not matter whether the elevator is hydraulic or electric.

Which Pump Do I Use?

It is rare for most elevator sump pumps to operate. They most likely will be needed in a fire emergency and we want them to operate flawlessly. We suggest engineers specify a 2” pump for 50 GPM single elevators. We default to the Bell & Gossett “Best” series 2EC for two reasons: Silicon Carbide seals and oil resistant wiring. This is a good choice whether the elevator is hydraulic or electric. We do have less expensive pump options if the project is cost sensitive in this safety area. Visit our Sump and Effluent section of the “Sump and Sewage” page for more details on the options we call Good, Better, and Best. This section also compares relative costs.

A Complete, Ready to Specify Package for Michigan Hydraulic Elevators

In Michigan, there are several options for the installation of the sump pump in hydraulic elevators. Our website has links to publications from the State of Michigan Department of Licensing and Regulatory Affairs (LARA).

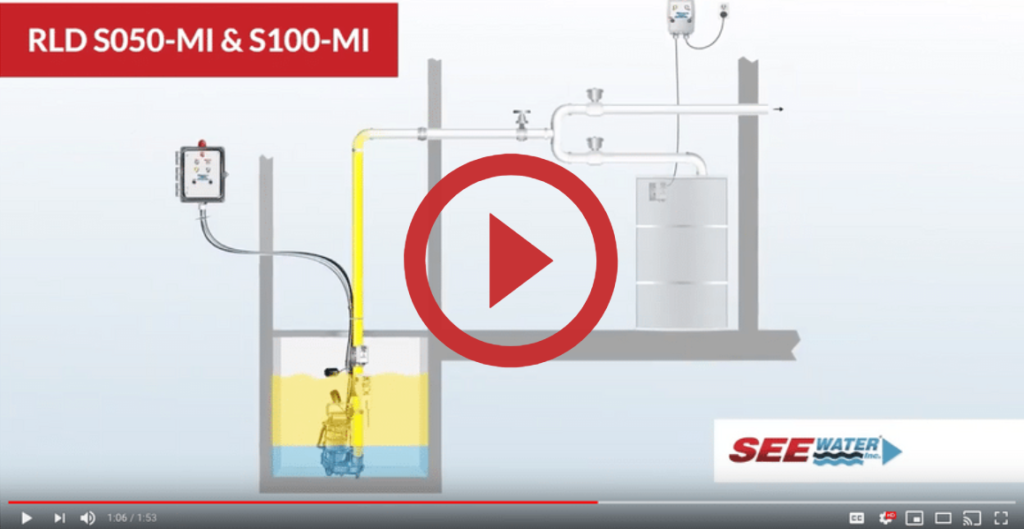

Once you have selected a “best” pump that can handle oil, there are two main concerns. The first is that you cannot turn the elevator sump pump off if the fluid level has activated the pump. It does not matter whether the fluid is water or oil, don’t turn the pump off. The second concern is to avoid pumping hydraulic oil into the sewer system.

Oil/water separators can be expensive to install and locate in the facility. The option we have detailed on our Elevator Sump Pump webpage satisfies both requirements while keeping costs down and limiting the space used in the building. This option uses a code approved panel and controls to determine whether the fluid is oil or water. The system then activates the appropriate solenoid to direct the fluid to the sewer or to a small waste storage drum.

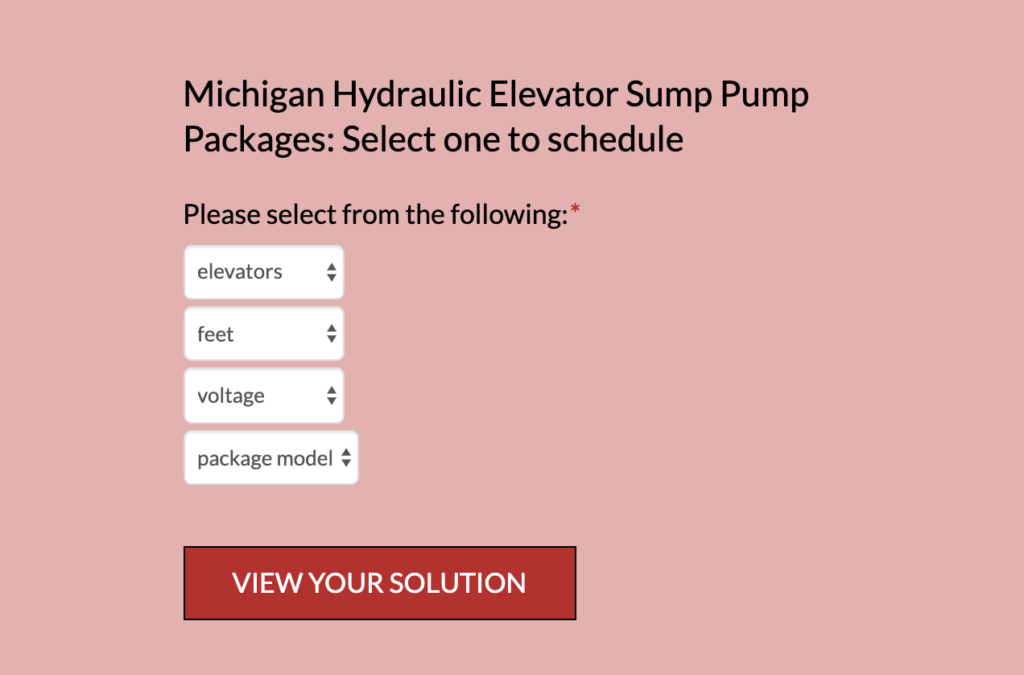

Here is a handy widget for sizing the RLD elevator sump pump systems. Try it out:

The widget is also located on the website for use when you need it. Next week we will look at the Ohio elevator sump pump systems.