The State of Ohio elevator codes leaves the solution of pumped hydraulic oil and water to the design engineer. Our updated R. L. Deppmann plumbing webpage includes a section on these sump pumps. Today we offer a few options for designers selecting sump pumps for projects in Ohio.

The State of Ohio elevator codes leaves the solution of pumped hydraulic oil and water to the design engineer. Our updated R. L. Deppmann plumbing webpage includes a section on these sump pumps. Today we offer a few options for designers selecting sump pumps for projects in Ohio.

Sump Pump Flow Rate Capacity in Elevator Pits

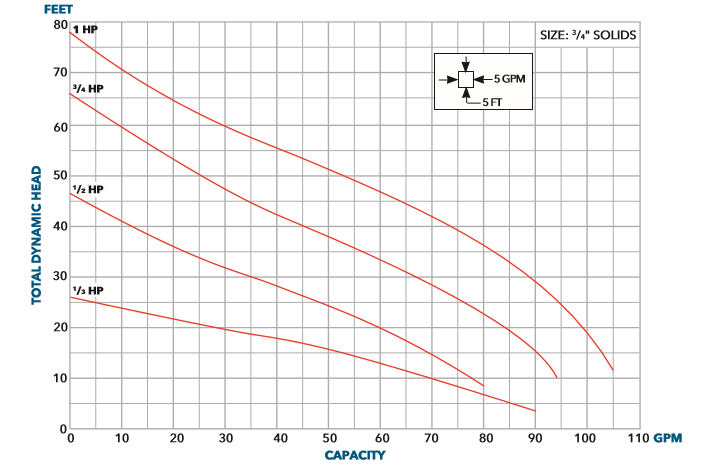

ASME has a safety section dedicated to elevators and escalators. Section A17.1 2.2 indicates “ […] all elevator pits for elevators that have Firefighters’ Emergency Operation, be provided with a drain or sump pump. The pit drainage shall be designed to remove a minimum capacity of 3,000 gallons per hour per elevator car”. As a result, each elevator must have a pumping capacity of 50 GPM. One shaft with one elevator will require 50 GPM. One shaft with two elevators will require 100 GPM.

This will not matter whether the elevator is hydraulic or electric.

Which Pump Do I Use?

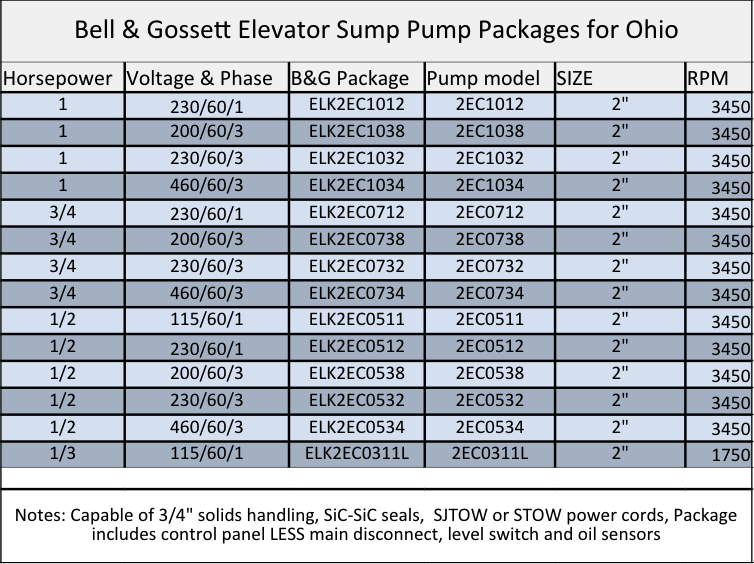

It is rare for most elevator sump pumps to operate. Most likely, they will be needed in an emergency and we want them to operate flawlessly. We suggest engineers specify a 2” pump for 50 GPM single elevators. We default to the Bell & Gossett “Better” series 2EC for two reasons: Dual seals and oil resistant wiring. This is a good choice, whether the elevator is hydraulic or electric. We do have less expensive pump options for electric elevators if the project is cost-sensitive in this safety area. Visit our Sump and Effluent section of the “Sump and Sewage” page for more details on the options we call Good, Better, and Best. This section also offers relative costs when comparing different options.

Once you have selected a “better” pump, which can handle oil, there are concerns. The Ohio plumbing code 4101:301.6 indicates the elevator shaft sump pump should be “…indirectly connected to the plumbing system”. If there is oil present, what do you do with the oil? Although the elevator code does not directly address the oil, the EPA is concerned about pumping hydraulic oil into the sewer system.

What Do I Need for Sump Pump Controls in Ohio?

The International plumbing code requires either an oil/water separator or an oil sensing alarm system. The State of Ohio plumbing code (OPC) was modified to delete this requirement. I thank Chip Updyke, the Chief of the Elevator Section of the Ohio Commerce Department, for clarification on this point.

So, the reality is that the engineer may simply specify a properly-sized sump pump for the application with a typical on-off “oil rated” float switch for operation. It would be up to the engineer to design the “indirect connection.” It is also up to the engineer or owner to figure out what to do with the oil pumped with the water.

R. L. Deppmann has a solution available for engineers and designers who are looking for an answer to the issue of oil in the water.

A Complete, Ready to Specify Package for Ohio Hydraulic Elevators.

Obviously, the engineer could install an oil/water separator on the project. Oil/water separators can be expensive to install and locate in the facility. Bell & Gossett offers an oil sensing system that will pump water but shut down in the presence of oil.

The Bell & Gossett ELK elevator sump pump package comes complete with controls and a panel. Everything is included except a main disconnect, pipe, and valves.

We also have packages that will pump into a small remote storage tank to provide an indirect connection. Call if you are interested in the S050-OH or S100-OH packages.