Pump shaft to motor shaft alignment is a critical part of the startup process that our service technicians perform on a daily basis. If a pump shaft and motor shaft are not properly aligned, it can lead to the following issues:

Pump shaft to motor shaft alignment is a critical part of the startup process that our service technicians perform on a daily basis. If a pump shaft and motor shaft are not properly aligned, it can lead to the following issues:

- Excess Noise

- Excess Vibration

- Shortened Seal Life

- Premature Pump and Motor Bearing Failures

- Coupler Sleeve Disintegration or Melting

The Two Types of Pump Shaft Misalignment

There are two types of misalignment and you can have both types in the same pump at the same time. These can occur both in the vertical and horizontal positions.

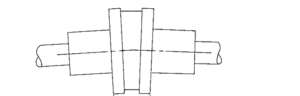

The first is Angular Misalignment where the shafts are not parallel:

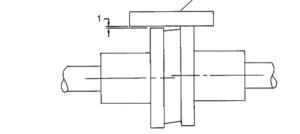

The second is Parallel Misalignment where the shafts are not parallel and have an offset:

Methods of Shaft Alignment

There are many methods to perform a shaft alignment on a flexible coupled pump. Here are the most commonly used methods:

- Straight Edge Alignment

- Rim-Face Dial Indicator Alignment

- Reverse Dial Indicator Alignment

- Laser Alignment

The list above is arranged in an order of least cost of no special tools required to higher cost of having a Laser Alignment tool.

The Rim Face Method and Reverse Dial Method both require some complicated math to achieve the proper alignment whereas the Laser Alignment tool does the math internally for the user. Regardless of which method is used, precision pump shims are a required material of the alignment process. Smaller pumps can be straight edge aligned where larger pumps are usually laser aligned. The alignment tolerances also get tighter as the rpm of the motor increases.

A proper alignment will include aligning the pump shaft to the motor shaft in both the horizontal and vertical planes.

Always follow the manufacturer’s instruction manual on how to properly align the pump as it can vary from one coupler type to another.

Remember to always have your pump aligned when replacing or moving the motor after maintenance has been performed on your pump. This will give your equipment the best possibility of minimizing issues and achieving its maximum life.

Take a look at this video where Shane Lombard, a Deppmann Service Technician, performed a straight edge alignment on a base mounted pump in a previous Service tip of the month.

Stay tuned for next month’s new Service Tip where we will show you how to align a pump using one of our Laser Alignment Tools.

If you have any questions, please reach out to the Deppmann Startup and Warranty Team.