Reduced cost is often viewed as the reason parallel pumping exists as a design option for engineers. In today’s hydronic heating and cooling systems, we are using variable speed drives for almost every pump. Will I save energy using parallel pumps? Will I save on construction costs if I use parallel pumping? I can’t say these are questions on everyone’s mind, but they are the subject of today’s R. L. Deppmann Monday Morning Minutes.

Reduced cost is often viewed as the reason parallel pumping exists as a design option for engineers. In today’s hydronic heating and cooling systems, we are using variable speed drives for almost every pump. Will I save energy using parallel pumps? Will I save on construction costs if I use parallel pumping? I can’t say these are questions on everyone’s mind, but they are the subject of today’s R. L. Deppmann Monday Morning Minutes.

Parallel Pumping and Energy Cost

If I stage parallel pumps and allow the operating pump to move out on the pump curve, will I save energy? The historical answer to this question was always yes. That “yes” often comes from us older engineers in the industry thinking about constant speed pumping. (OK, I’ll satisfy the HR people and say seasoned rather than older.) When we use variable speed pumps, which is most of the time, the answer becomes “yes, but is it a lot.”

Let’s look at two examples. A heating example could compare a single 500 GPM at 60 feet pump using a 15 HP motor with a parallel selection of two 250 GPM, 7-1/2 HP pumps. The energy used with parallel pumps compared to a single pump results in over 10% of savings. This is a large percentage, but since the horsepower is so small, the savings is about $600.00 per year. Is that worth the complexity of parallel staging of pumps?

In a chilled water example, I use a single 4000 GPM at 200 feet, 300 HP pump and compare it with two 2000 GPM, 150 HP pumps. In this example, the energy savings for parallel pumps were under 5%. This is a small percentage, but the savings were over $2,100.00 per year. It is worth the complexity.

Where do we draw the line for the efficiency of parallel pumps vs. a single operating pump? When will the energy savings make a difference? Here are a couple of quick thoughts.

- You do not need a standby pump.

- The system is sized for over 30% future capacity, you should review parallel pumping.

- The single pump is 30 HP or more and the parallel pump non-overloading HP in 50/50 operation is not over ½ the single pump HP. (Example: 15 HP, not 20 HP)

- The control head is over 50% of the design pump head. (Think pressure boosters)

Besides energy cost, there can be a great savings in first cost so let’s look at that.

Parallel Pumping and Installation Cost

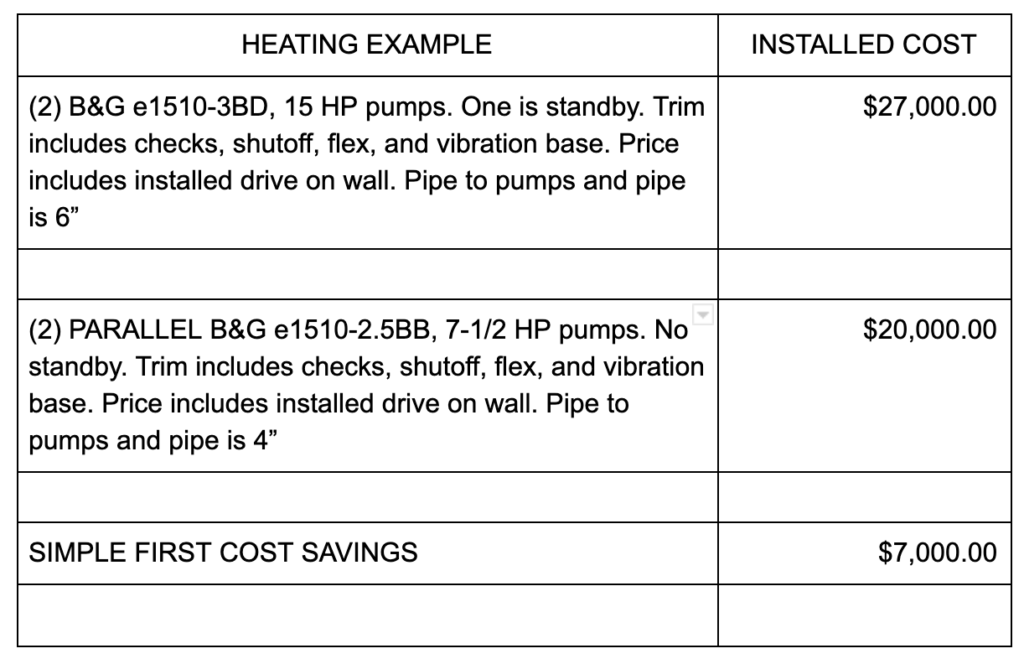

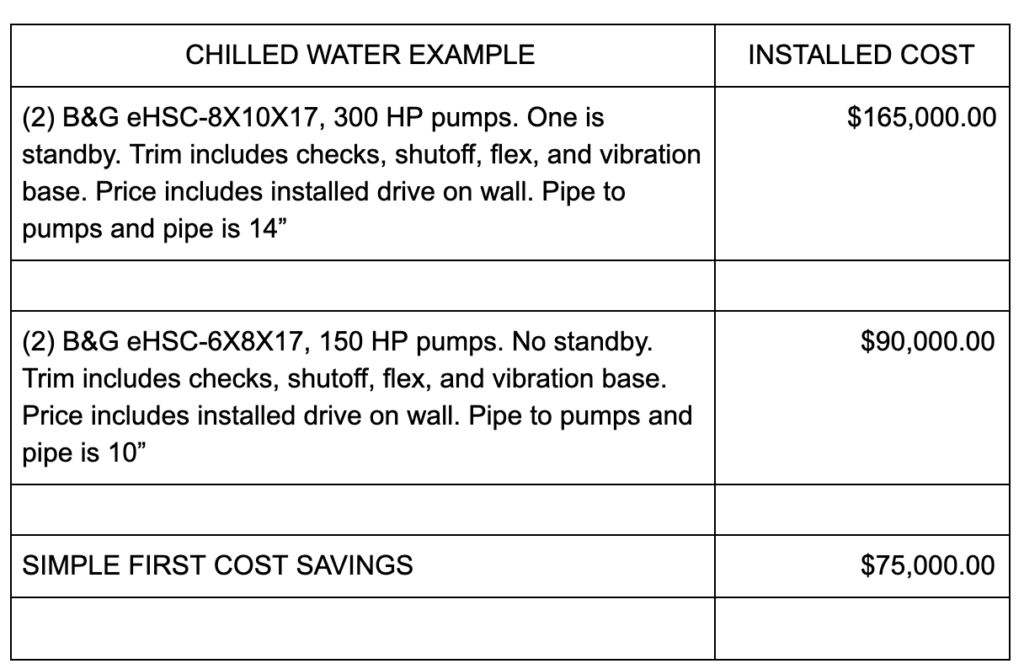

We live in the world of building construction and first cost is always important. Parallel pumping can result in a lower installed cost. Simply put, 7-1/2 HP pumps will cost less than 15 HP pumps. 4” pipe and fittings will cost less than 6” pipe and fittings.

If the pipe valves and fittings dropping down to the parallel pumps are sized for the flow of the pump, the savings can be huge. Let’s look at the two examples I used above. I asked a local contractor in Ohio for some installation costs. I also priced up the pumps, drives, and pump trim. Obviously, cost depends on circumstances, but this should get us close to understanding the savings with parallel pumps.

This is a clear case of size does matter. The difference in piping makes a difference. If the pipe is 4” vs. 3”, there will not be much installation savings. Once we get to pipe sizes over 6”, it makes a big difference. If your mains are 10” or larger, it is always worth looking at.

Next week we will summarize the parallel pumping advantages and offer some specifications and scheduling tips.

HVAC Hydronic Series:

Article 1: What is parallel pumping and why do it?

Article 2: Selecting parallel pumps and the curve

Article 3: Controlling parallel variable speed pumps

Article 4: Parallel pumping and standby capacity

Article 5: Parallel pumping and cost

Article 6: Parallel pumping specifications