Commercial heat pump water heaters using R-744 (CO2) refrigerant operate best when attention is paid to the piping and storage tank arrangement. Today, in part four of this series, we look at temperatures and tank piping for the best return on investment.

Water Heater Types

Before we look at the piping and storage of commercial heat pump water heaters, I want to get some terms straight.

Tank Type: The traditional tank type water heaters couple a high efficiency burner with a tank. Shown below as examples are the PVI Conquest gas fired and Durawatt Electric water heaters.

There are hybrid tank type heat pump water heaters on the market. They use a heat pump and electric elements so they will work in cold weather conditions. These units are limited to smaller residential applications due to the size of the heat pump components.

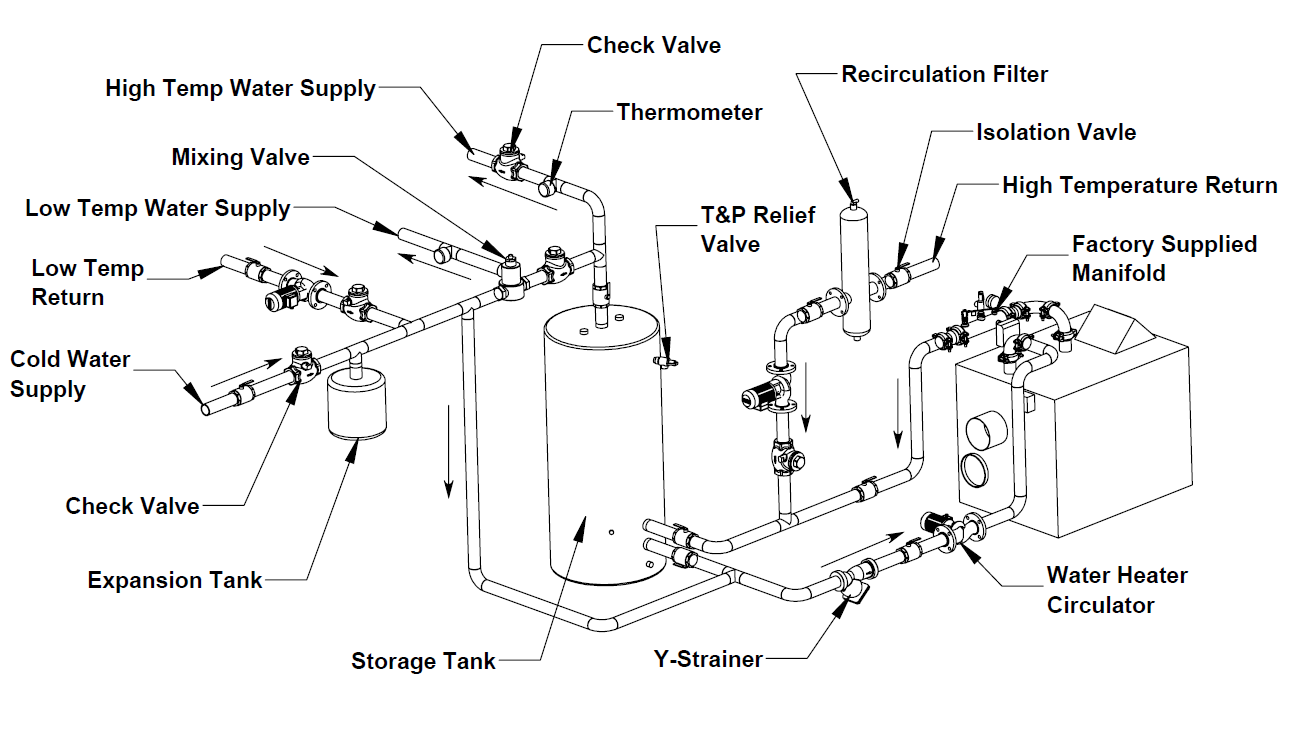

Volume Water Heaters or Tank & Heater: The commercial volume water heater has been around for a long time. It is a boiler and a separate tank with a pump to circulate the water between the two pieces. This allows the heater to be smaller in BTUH capacity while using the storage volume to handle the actual load.

The tank in this type of heater will have some stratification. The hottest water is at the top near the outlet and cooler water is down near the bottom. There is a very small gradient between the two. The heater will normally be a high flow rate, low temperature difference appliance. The delta T (ΔT) of the heater is often designed for a 20°F to 40°F maximum temperature rise. This means if we want a tank with 140°F storage at the top, the water going to the heater will be about 100°F subject to the circulating pump capacity

The traditional volume water heater is a multi-pass water heater. The pump pulls water out of the tank at a higher GPM, and it takes multiple passes before the tank gets to the storage temperature.

You can read more about these types of water heaters at Commercial Gas Fired Water Heater Types.

Water Inlet Temperature and COP

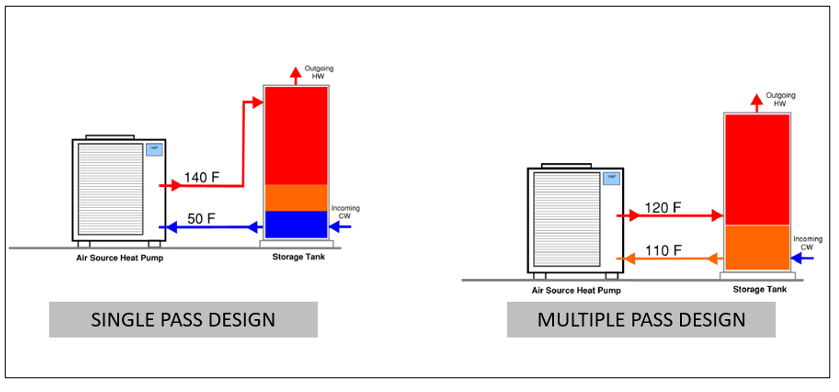

The natural refrigerant R-744, also known as carbon dioxide, works best when the domestic water inlet temperature is low. In the multiple pass style water heaters, as explained above, the return water temperature is only 20 to 40 degrees below the design storage temperature. If we did this with a heat pump and tank, the higher return temperature would reduce the coefficient of performance (COP) of the heat pump. The COP could be as low as half if we used a multi-pass design.

With R-744 we want the heat pump inlet temperature as low as possible. In water heaters located in Michigan and Ohio, that will often be a design temperature of 40°F. This will lead us to the use of a single pass piping design. This design will use a high ΔT and a low flow rate. The water will heat from 40-140°F in a single trip through the unit, hence the term “single pass.”

This could even require multiple heat pumps in series to reach a desirable higher storage temperature.

We recommend single pass piping for the Lync® by WATTS Aegis heat pump water heater packages.

Water Outlet Temperature and Carbon Dioxide Heat Pumps

We continue to recognize that R-744 filled heat pumps can be the preferred type for safety, reduced global warming, and future availability. Once we make the decision, or future regulation forces us, to use carbon dioxide refrigerants, how should our commercial building domestic hot water heater designs change? One change will be the single pass design piping. The other big change is the storage temperature.

The R-744 heat pump compressors can provide much hotter outlet temperatures than the higher global warming potential refrigerants. Why not take advantage of this? We may want to store water at 160°F when using R-744. Storing water at 160°F will obviously require master or point of use mixing valves to drop the temperature to the usable temperature required by code. We use these already due to code or if our designs are already storing at 140°F.

Storing water at 160°F will have two key advantages. 1) It allows us to reduce the storage volume by approximately 25%. 2) The storage temperature reduces the pathogen (Legionella) mitigation disinfection dwell time. For example, at 140°F it takes 32 minutes to inactivate 99.99% of Legionella bacteria. At 160°F, that dwell time is reduced from 32 minutes to about 2-3 seconds.

The drawback to higher storage temperatures is reduced COP. The reduction in performance is not nearly as severe as high temperature storage with gas-fired or resistance electric equipment, but it should be considered when deciding on the best solution for a particular application.

The carbon dioxide commercial heat pump is the preferred type. Given that, we want to be able to handle cold inlet water and we want hot outlet water. Our piping and tank storage design will reflect this. In the next R. L. Deppmann Monday Morning Minutes we will look at an example system and discuss more about the storage tank piping.

See the rest of the series here:

Heat Pump Water Heaters: The Road to Decarbonization (Part 1)

Heat Pump Water Heaters: How They Work (Part 2)